Overview

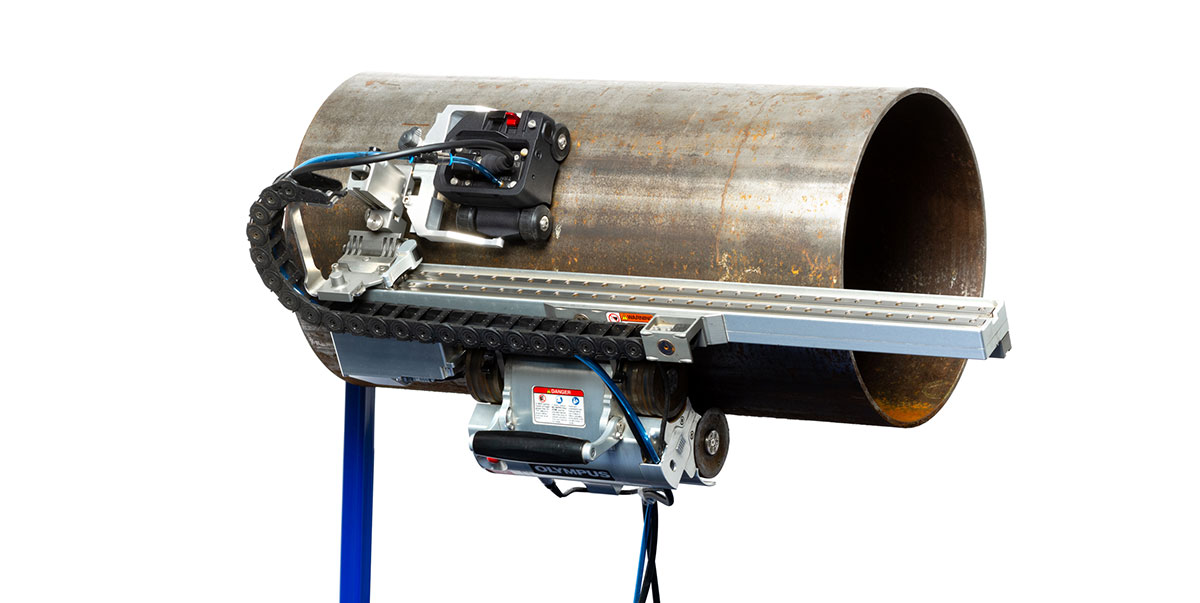

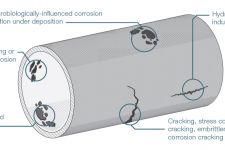

An easy-to-deploy 2-axis encoding phased array (PA) solution, the semiautomated HydroFORM™ scanner enables fast and reliable wall-thickness mapping and midwall damage detection by acquiring high-resolution data of large surfaces in minimal time. While the standard HydroFORM package comes equipped with the proven phased array linear probe and local immersion system, you can now choose for a dual array probe configuration. Both options allow for a resolution of up to 1 mm × 1mm. To optimize the productivity of raster scanning, the HydroFORM system is equipped with several efficiency-boosting features:

| |

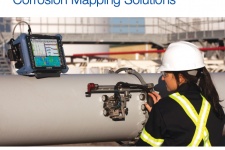

Easily adapting to curvatures 4 in. OD (101 mm) and greater, this PA solution facilitates a wide range of applications including:

|

XY mapping principle on pipes with the HydroFORM and ChainSCANNER. | High-Performance Corrosion Mapping for Rough and Uneven Surfaces Using the I8 Local Immersion SystemAchieve immersion-tank-quality phased array inspection without concerns about water coupling. The HydroFORM scanner's unique low-flow water-column design with foam gaskets conforms to the surface, eliminating the need for a wedge. Other innovative features of the HydroFORM water-coupling system:

|

Effortless High-Resolution Corrosion Mapping with the REX2 DLA ProbeIncrease the versatility and efficiency of corrosion mapping with the HydroFORM scanner by opting for the REX2 Dual Linear Array™ probe.

|  |

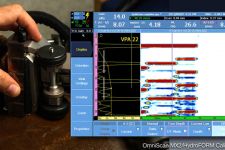

ScanDeck™ ModuleIntegrated Controls and Status IndicatorsThe ScanDeck module is like your scanning dashboard, situated directly in your eyeline while you operate the HydroFORM scanner. Using a combined HydroFORM and OmniScan™ X4 solution, you fully benefit from all the functionalities of the ScanDeck module. Control button:

Indicator LEDs:

|

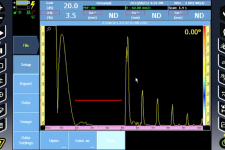

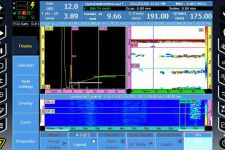

Complete PA SolutionHydroFORM Scanner and Omniscan™ X4 Multitechnology Flaw DetectorBy combining a water column system with gate synchronization on the interface echo available in the OmniScan X4 software, the HydroFORM scanner provides class-leading signal quality, reliable remaining wall measurements, and an enormous improvement in flaw characterization and imaging over conventional UT. When combined with the REX2 DLA probe, the HydroFORM scanner further improves the near-surface resolution for applications where a constant water flow is impractical or logistically impossible. The REX2 DLA probe is also compatible with the latest advanced ultrasonic technologies, such as TFM and PCI. |

Configurations

Manual Encoded

An easy-to-deploy 2-axis encoding PA solution, the HydroFORM scanner has integrated X and Y axis encoders. | Semiautomatic

The HydroFORM mounted on a MapSCANNER. |

Automatic

Conduct automated 2-axis corrosion mapping at high acquisition rates using the motorized MapROVER™ scanner and HydroFORM scanner. |

Achieve PA corrosion mapping in difficult-to-reach locations using the remote-controlled SteerROVER™ motorized scanner and HydroFORM scanner. |

HydroFORM Specifications

| HydroFORM | DLA Corrosion | DLA Corrosion | |

| Phased array probe | 7.5L64-I8 | REX2 | REX2-1DEG |

| Maximum one-line scan coverage (width) | 60 mm | 60 mm | 60 mm |

| Delay line medium | Water | Rexolite | Rexolite |

| Delay line height | 14 mm or 38 mm | 7.5 mm | 7.5 mm |

| Roof angle | N/A | 5° | 1° |

| Maximun inspection thickness (in steel) |

50 mm (14 mm delay line)

150 mm (38 mm delay line) | 30 mm (recommended) | 95 mm (recommended) |

| Typical near-surface resolution (1/8 in. FBH) | 1.5 mm | 1 mm | 1 mm |

| Depth resolution | 0.1 mm | 0.1 mm | 0.1 mm |

| OD inspection range | 4 in. and greater | 4 in. and greater | 4 in. and greater |

| ID inspection range | 10 in. and greater (16 in. with index encoder) | 10 in. and greater (16 in. with index encoder) | 10 in. and greater (16 in. with index encoder) |

| Dimensions | 16 cm × 12 cm × 8.5 cm with index encoder | 16 cm × 12 cm × 8.5 cm with index encoder | 16 cm × 12 cm × 8.5 cm with index encoder |

| Scanner compatibility | ChainSCANNER, SteerROVER, MapSCANNER, and MapROVER | ChainSCANNER, SteerROVER, MapSCANNER, and MapROVER | ChainSCANNER, SteerROVER, MapSCANNER, and MapROVER |