![]()

Fuel Injection Nozzle and Needle Tip

Background

A vehicle’s overall quality is equal to the sum of its parts, and it is imperative for manufacturers to maintain rigid standards of excellence for every component. Manufacturers must also take into account requirements such as emission reduction, fuel efficiency, long-term durability, and regulatory standards. The increasing complexity of auto parts and components also requires manufacturers to place a strong emphasis on material characteristics, fitting tolerances, and technical cleanliness, which all play a strong role in the long-term durability, durability, and life-expectancy of the final product.

Application

During operation, a needle blocks the fuel injection aperture at the tip of the nozzle. The needle is electromagnetically lifted to provide pressurized injection of the fuel. To completely close off the fuel injection aperture, the configuration of the two components needs to match precisely. This calls for highly precise measurement equipment capable of evaluating the configuration of both parts.

The Olympus solution

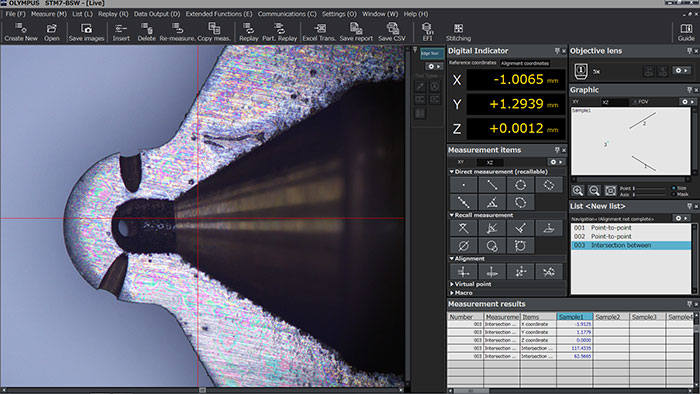

Olympus STM7 measuring microscopes’ dedicated calculation software offers automatic recognition of end sections, allowing for an almost total elimination of the positioning errors caused by manual adjustment.

Upper:Injector nozzle

|

Sectional view of injector nozzle | ||

STM7 calculation software GUI