Background

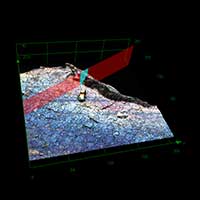

Machining parts by punching and stamping can be problematic because the process typically creates shear droops with smooth surfaces on the punch side and burrs with serrated surfaces on the die side. This makes subsequent machining difficult if the workpiece is thick or if the material is difficult to process, such as stainless steel or titanium. In addition, the speed and accuracy of punching and press machining has remained stagnant. Because of these issues, laser cutting has become increasingly popular. Two advantages of laser cutting are that it works well on a variety of materials and yields high quality finished products. While laser cutting does not produce shear droops or burrs, the heat of the laser sometimes causes material to melt off the workpiece and adhere to the back of the laser-irradiated plane. To help prevent adhesion, molten material is blown off by an assist gas before it cools. In some cases, though, a portion of material is able to re-solidify. This unwanted material is called ‘dross.’ To ensure the accuracy of laser cuts and the quality of finished products, the amount of dross must be carefully measured (Figures 1 and 2).

The Olympus solutions

The Olympus LEXT 3D laser measuring microscope enables you to make non-contact, highly accurate 3D measurements on workpieces to evaluate the size and shape of dross. The microscope’s high inclination sensitivity makes accurate measurements of dross with complex geometries and steep angles.

Features of the product

The Olympus LEXT makes 3D microshape, non-contact measurements. The microscope features ultra-high-resolution measurement capabilities with a high pixel density to ensure accuracy. The LEXT’s high inclination sensitivity is excellent for making accurate measurements of complex and steep-sided dross.

Image

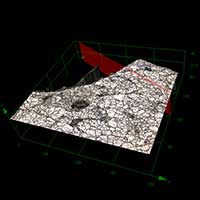

Figure 1: High-resolution image of incoming laser side of a workpiece and associated measurements

Figure 2: High resolution image of outgoing laser side of a workpiece and associated measurements showing dross