The X-ray detector in your analyzer has a small window that enables the X-rays to enter and reach the detector. Without this, the analyzer wouldn’t work. What this window is made of is important and impacts the effectiveness of your device. Light elements (like magnesium, aluminum, and silicon) have the weakest X-rays, so the thinner and lighter the window, the more of these X-rays can pass through. The more X-rays can pass through, the better the sensitivity of your XRF analyzer.

For a long time, the window was made of a beryllium foil. Beryllium is very light, but it’s hard to manufacture, fragile, brittle, and toxic. Even relatively slight impacts can damage the window, and, if it breaks, it’ll need to be replaced. Most beryllium windows are 8 microns or more thick.

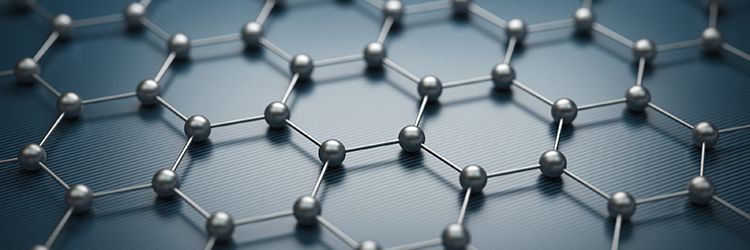

Vanta™ VMR models are now equipped with graphene detector windows that are only 0.9 microns thick, enabling better light element detection than conventional beryllium windows.

Advantages of graphene

Graphene is made of carbon; even though the window is very thin, it’s incredibly strong. Graphene windows allow more X-rays to pass through, increasing the analyzer’s sensitivity to key light alloy elements such as magnesium (Mg), aluminum (Al), silicon (Si), and even phosphorus (P) and sulfur (S). In addition, graphene is not toxic, unlike beryllium.

The unique benefits of graphene enable the Vanta model VMR handheld XRF analyzer to:

- Detect magnesium (Mg) faster in aluminum alloys (0.53% Mg in 3 seconds of beam 2)

- Achieve lower limits of detection for aluminum (Al) in nickel alloys

- Measure silicon (Si) under 1000 ppm in low-alloy steels faster and with better precision

- Measure phosphorus (P) and sulfur (S) in low-alloy steels below 0.035%

Related Content

Vanta for Light Element Detection Info Sheet

Video: Innovations for Vanta Analyzers and the Graphene Window

How Recent Handheld XRF Developments Impact Alloy PMI Testing