9.6 Phased Array

This tutorial has focused on conventional flaw detection using single element and dual element transducers. But as ultrasonic NDT technology develops, phased array systems that use sophisticated array probes with as many as 256 or more elements are seeing increasing use in industrial settings to provide new levels of information and visualization in common ultrasonic tests that include weld inspection, bond testing, thickness profiling, and in-service crack detection.

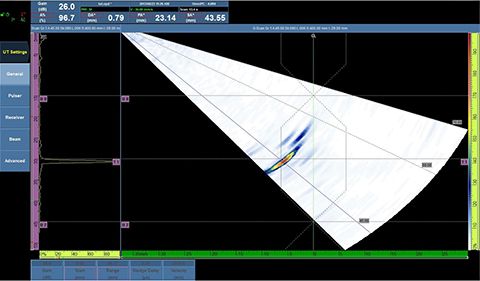

The benefits of phased array technology over conventional UT come from its ability to use multiple elements to steer, focus and scan beams with a single transducer assembly. Beam steering, commonly referred to sectorial scanning, can be used for mapping components at appropriate angles. This can greatly simplify the inspection of components with complex geometries. The small footprint of the transducer and the ability to sweep the beam without moving the probe also aids inspection of such components in situations where there is limited access for mechanical scanning. Sectorial scanning is also typically used for weld inspection. The ability to test welds with multiple angles from a single probe greatly increases the probability of detection of anomalies. Electronic focusing permits optimizing the beam shape and size at the expected defect location, thus further optimizing probability of detection. The ability to focus at multiple depths also improves the ability for sizing critical defects for volumetric inspections. Focusing can significantly improve signal-to-noise ratio in challenging applications, and electronic scanning across many groups of elements allows for C-Scan images to be produced very rapidly.

For further information on phased array testing, Olympus NDT has a brief Introduction to Phased Array and a comprehensive Phased Array Tutorial.