Application

Using ultrasonic testing to identify the presence or absence of bonding between an outer layer of high impedance material, such as metal or ceramic, and an inner layer of low impedance material, such as plastic, composite, or rubber. This technique also applies to many metal-to-metal glue joints.

Background

When materials of similar acoustic impedance (density multiplied by sound velocity) are joined to each other, such as metal welded or brazed to metal, or plastic fused to plastic, the presence or absence of bonding can usually be determined from the amplitude of the first reflection from the boundary. Typically, there will be a significant difference in reflected signal amplitude between bonded and disbonded conditions. However, if there is a large difference in the acoustic impedance of the two materials, as in the case of bonds between metal and polymers, then that acoustic impedance mismatch will cause a significant reflection from the boundary even if the materials are mechanically bonded. The change in echo amplitude between bonded and disbonded conditions may be small and hard to detect, especially in situations where transducer coupling conditions are not uniform. This same situation often occurs in cases where metal is bonded to metal by means of epoxy or other low impedance adhesives. Unless the adhesive layer is extremely thin, it will constitute a low impedance bond line with a significant reflection, even from a good joint.

Equipment

This test can be performed with any standard ultrasonic flaw detector, such as the EPOCH® 650 or EPOCH 6LT flaw detector. Ultrasonic pulser/receivers can also be employed. The transducer will usually be a common delay line transducer in the frequency range between 2.25 MHz and 20 MHz, such as a V207-RB, V206-RB, V202-RM, or V208-RM. The specific transducer for a given test will be selected based on material thickness, geometry, and acoustic properties.

Procedure

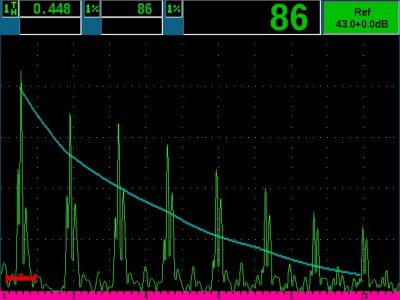

Set gain such that the first backwall echo from a well bonded reference sample is at 80% screen height, and set screen range large enough to display a series of backwall echoes. In the first waveform below, the first peak is the delay line interface echo, and the subsequent peaks are multiple backwall echoes from 0.1 in. (2.5 mm) steel bonded to a plastic liner. Because the metal is bonded to a backing material, the bonded polymer on the back side of the steel acts as a mechanical damping mechanism, and the echoes decay relatively quickly. It is helpful to use the DAC function to draw a curve marking the ringdown envelope from a known good bond.

Slow ringdown pattern from bonded metal, DAC curve set as reference:

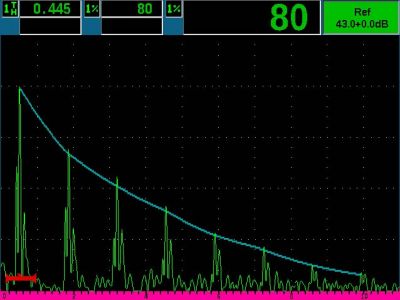

| If these two materials are disbonded, the damping effect is removed and the peaks become larger, rising above the reference curve as seen below. |