Overview

Vanta™ iX In-Line XRF Analyzer for Automated Material Analysis

Keep Your Process Up to Speed

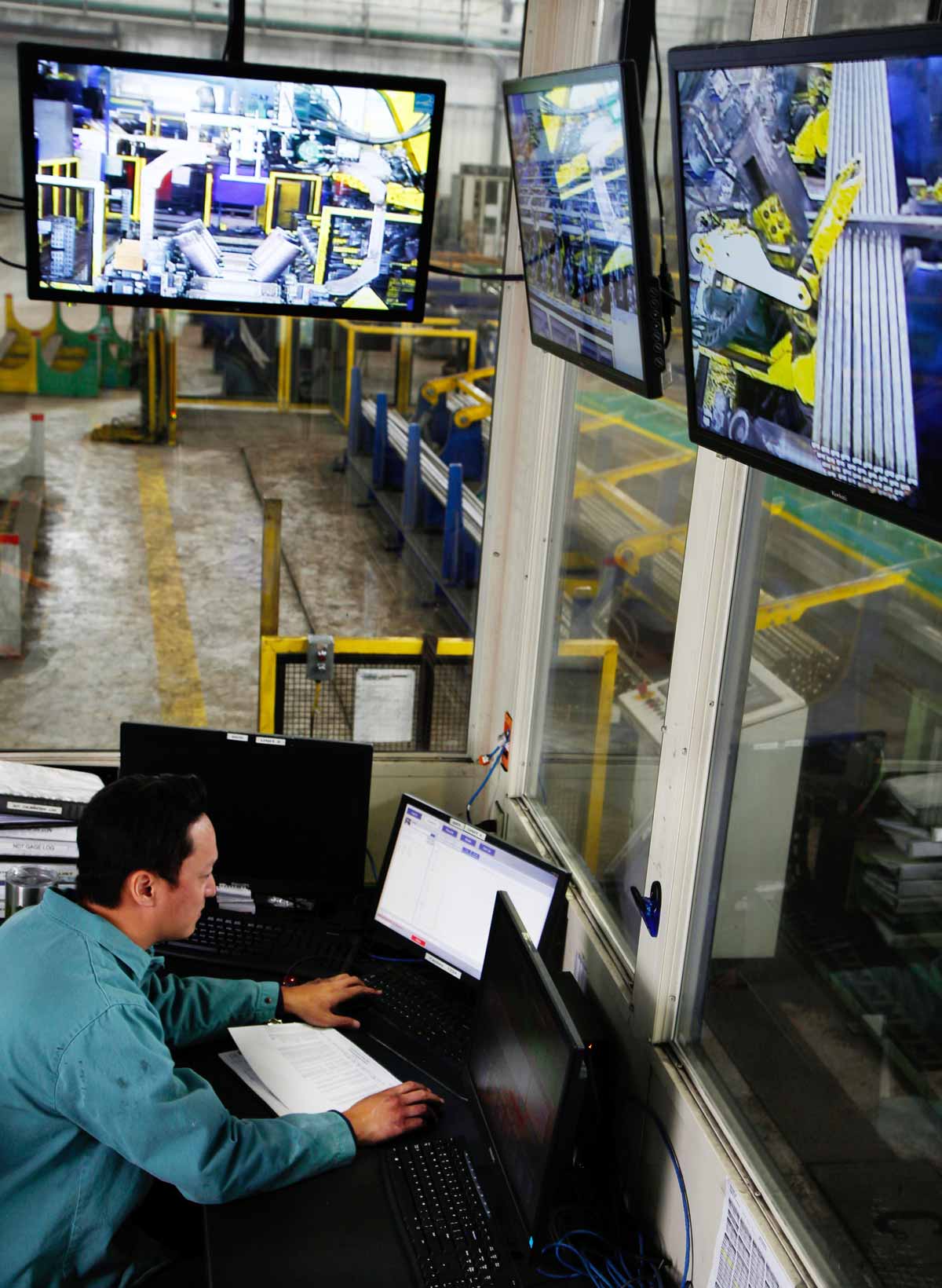

The Olympus Vanta™ iX in-line X-ray fluorescence (XRF) analyzer gives you confidence in your products by automating material analysis and alloy identification on the manufacturing line:

|

100% Inspection for Metal Fabrication of Tubes, Bars, and RodsFor organizations adopting Industry 4.0 practices and 24/7 process control to verify alloys with pass/fail analysis, the Vanta iX analyzer delivers material verification and lot/heat control for bar, billet, tube, and rod manufacturing, as well as machined parts and customized components. Automating your testing with a Vanta iX analyzer adds a competitive edge to your finished product since you can demonstrate that materials are 100% tested and verified. |

Scanning and Monitoring for Ore Grade Control in MiningFor geological processing and mining, the Vanta iX analyzer enables core scanning and on-belt analysis with real-time results to monitor process variability and ensure ore grade consistency. During on-belt analysis, the analyzer provides blending verification and process validation of concentrates. |  |

| Fast and Accurate Elemental Analysis for Continuous Quality ControlLike all Vanta electronics, the Vanta iX analyzer works fast while delivering reliable, actionable results to guide critical decisions.

|

Easily Integrates into a Variety of Production SystemsThe Vanta iX analyzer is versatile, compact, and easy to install—use the mounting holes on each side to mount the analyzer onto robotics and other systems. There is no external control box, so you can easily control the analyzer with either the Vanta Connect API or a PLC and discrete wire. Connector options:

|  |

Rugged for Greater Uptime in Manufacturing EnvironmentsThe Vanta iX analyzer is built to endure the high levels of vibration, electromagnetic and acoustical noise, dust, and moisture of production facilities for increased reliability and uptime.

A built-in heat sink lowers the internal temperature, while fan attachment points are available if additional cooling is needed. The analyzer offers toolless window changes for fast maintenance. |

Specifications

Vanta™ iX Specifications

| Dimensions (W × H × D) | 10 cm × 7.9 cm × 26.6 cm (3.9 in. × 3.1 in. × 10.5 in.) |

| Weight | 2.4 kg (5.29 lb) |

| Excitation Source |

X-ray tube: Rh or W anode (application optimized) 5–200 μA

MR model: 8–50 keV (4 W max) CW model: 8–40 keV (4 W max) |

| Primary Beam Filtration | Eight filter positions automatically selected per beam per method |

| Detector |

MR model: Large-area silicon drift detector

CW model: Standard silicon drift detector |

| Power | Power over Ethernet (PoE) or 18 V AC power adaptor |

| Elemental Range |

Method dependent:

MR model: Mg–U CW model: Ti–U (with standard window and calibration) |

| Pressure Correction | Built-in barometer for automatic altitude and air pressure correction |

| IP Rating | IP54 |

| Operating Environment |

Temperature range: –10 °C to 50 °C (14 °F to 122 °F) under continuous duty cycle

Humidity: 10% to 90% relative humidity, non-condensing |

| Operating System | Linux |

| Application Software | Olympus proprietary data acquisition and processing package |

Resources

BlogVidea |