Overview

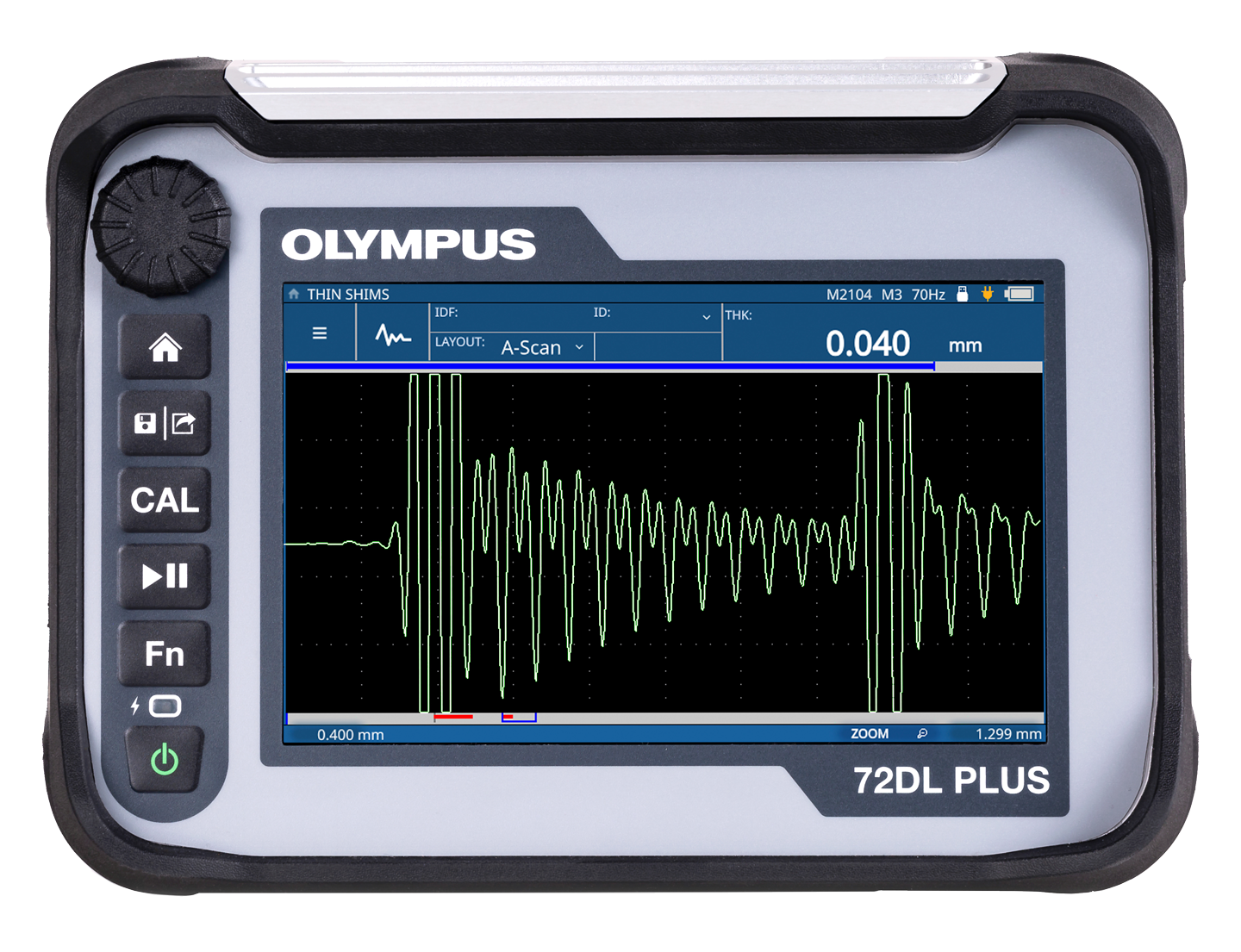

72DL PLUS™ Ultrasonic Thickness GaugeHigh-Speed, High-Frequency, High-Precision Measurements | |

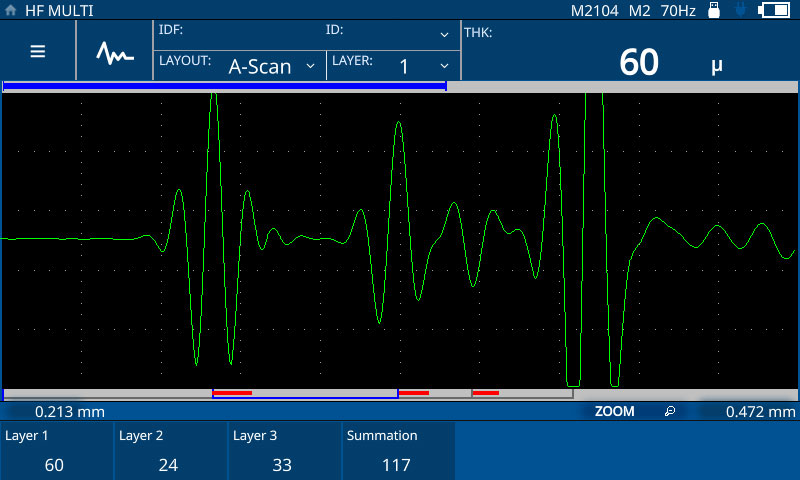

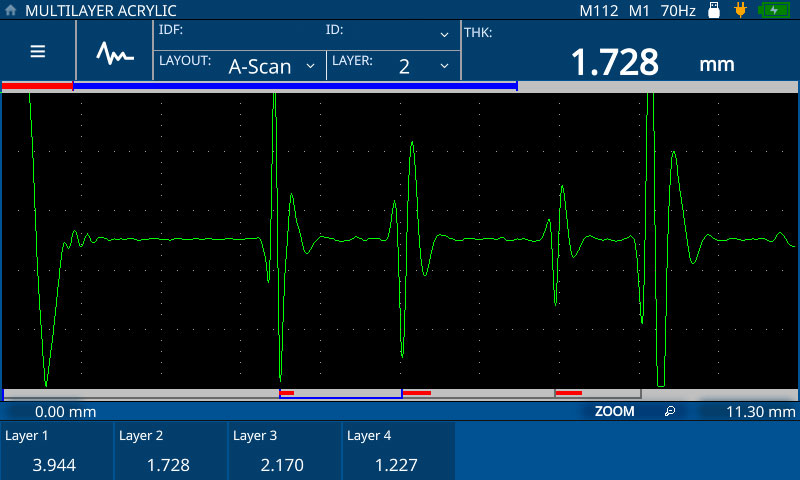

The 72DL PLUS™ ultrasonic thickness gauge delivers precision thickness measurements at high speed in a portable, easy-to-use device. With fast scanning, advanced algorithms, and our lowest-ever minimum thickness capability, you can confidently measure the thickness of very thin layers in the most challenging manufacturing applications. 72DL PLUS thickness gauges are available in standard frequency and high-frequency models. The high-frequency model can measure ultra-thin materials, including multilayer paint, plastics, metals, and coatings, and the Multilayer Measurement feature can simultaneously display the thickness of up to six independent layers. All 72DL PLUS models have the features to perform fast, accurate thickness measurements:

|

72DL PLUS Features at a Glance

Confidently Control Your Thickness Inspection Process

We’ve made precision ultrasonic thickness gauging easier with smart tools so you can set up, perform, and analyze your inspections faster and with more confidence.

- Large, clear screen: see thickness measurements on a 177.8 mm (7 in.) high-resolution touch screen WVGA display

- Versatile layouts: A-scan, B-scan, A/B-scan, trend, and zoom measurement layouts provide an accurate picture of thickness changes

- Guided inspection: Interactive part map with thickness measurement locations (TMLs) show a quick view of the inspection status and quality

- Inspection data management and analytics: internal data logging and PC interface application speed up inspection data collection and review

- Connected: supports Wi-Fi® and Bluetooth® for Industry 4.0 practices

- Easy application setup: create custom applications to reduce device setup time for routine thickness inspections

Intuitive User Interface with an Easy-to-View, Large Screen

- Wide viewing angle for outstanding visibility in most ambient conditions

- 177.8 mm (7 in.), full color touch screen provides access to the setup and measurement layouts

- Guided configuration makes it easy to change the settings based on your needs

Precision Ultrasonic Thickness Gauge Built for Industrial Environments

- Designed for IP65 to protect against dust and moisture

- Drop tested (MIL-STD-810G) to protect against falls and reduce the need for costly repairs

- Takes reliable measurements in a wide operating temperature range of –10 °C to 50 °C (14 °F to 122 °F)

- Portable for the production floor, weighing 2.1 kg (4.6 lb)

- Easy to control from the touch screen, key controls, and adjustment knob

- Can be used indoors and outdoors, on a work surface, or using a four-point chest harness or shoulder strap

- Long battery life up to 8 continuous hours

Measure the Thickness of Up to Six Layers for Multilayer Coatings, Paint, Plastics, and Other Materials

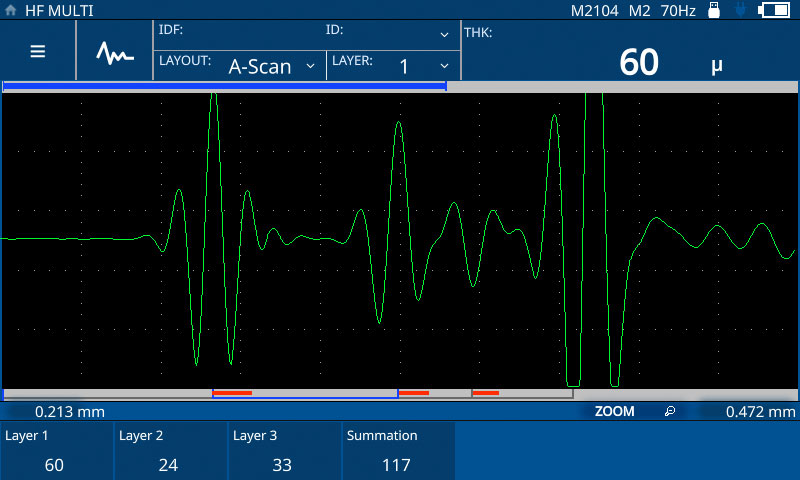

The Multilayer Measurement feature offers multilayer thickness measurements of up to six layers. Measurement settings for each layer—including material, velocity, target thickness ranges, and alarm thresholds—are easily accessible through the configuration workflow and touch-screen controls.

Workflow

Streamlined Thickness Data Collection and Processing

All 72DL PLUS™ models have built-in datalogging with up to 2 GB of data storage, along with convenient onboard file management features.

- On-screen alphanumeric keypad for file naming and editing report headers to organize your work

- File Manager menu makes it simple to review and edit application files, review and delete inspection data files, and see the inspection completion percentage; once a file is identified, it can be conveniently recalled

- Connect a foot switch for hands-free activation of the save/send data function

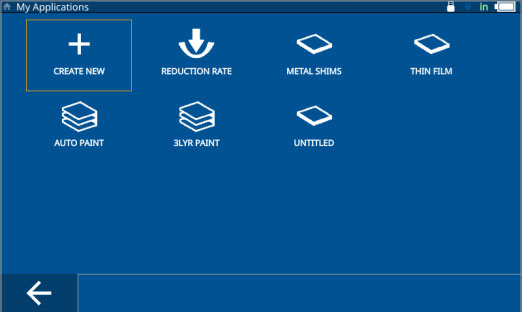

Easy Application Setup for Routine Thickness Measurements

For routine applications on simple or complex parts, store and recall settings in the My Applications menu to simplify the device setup process. This reduces manual selection and setting adjustments before each inspection, enabling efficiency and confidence in the measurement quality.

The My Applications menu makes it easy to create custom applications right from the gauge:

- Predefined configurations for single layer, multilayer, barrier, and reduction rate

- Menu guides you through each process step, from choosing the configuration for an inspection to setting up the transducer, material, alarms and alarm conditions, measurement mode, and the part map

- Applications are easy to recall—just turn on the gauge and the instrument shows the My Applications menu as the startup screen

For added flexibility, the PC Interface Application can also be used to create applications and send the files to different gauges on the production floor or across facilities.

Get to Work Fast with Standardized Inspection Guidance

With the interactive custom template, inspectors can do their job faster and without stress by following standardized inspection guidance on the gauge. Supervisors can have more security that a job is done right by intelligently monitoring the quality and progress of ongoing thickness inspections.

- Save time and resources training inspectors:create custom part maps and setups once and push them to all your instruments; all inspectors follow the same process to consistently evaluate the thickness of parts

- Confidence in your thickness inspections: know you’re capturing data at every required thickness inspection location; see progress with color-coded inspection points for each stage—before measuring, active thickness measurement location (TML), after measuring, and alarms/loss of signal (LOS)

- Easily retake thickness measurements as needed: quickly confirm out-of-spec measurements identified by alarms/LOS readings

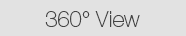

Track and Visualize Thickness Changes with Versatile Measurement Layouts

All 72DL PLUS models include five measurement layouts, so thickness changes on a test material can be accurately tracked and visualized.

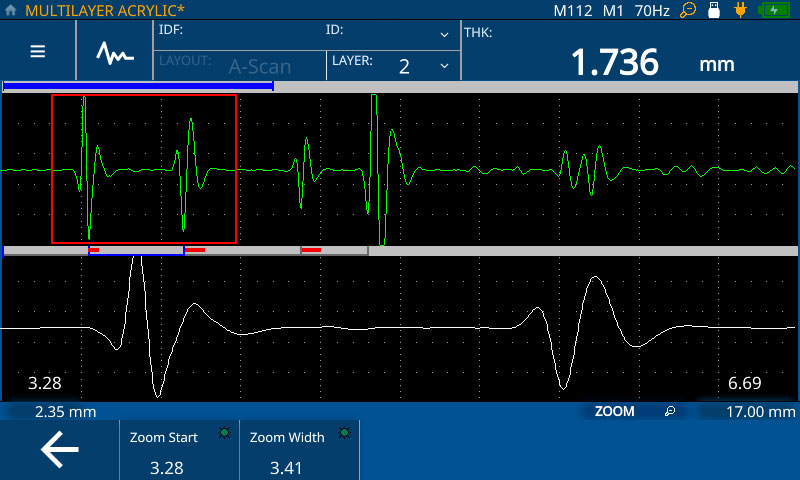

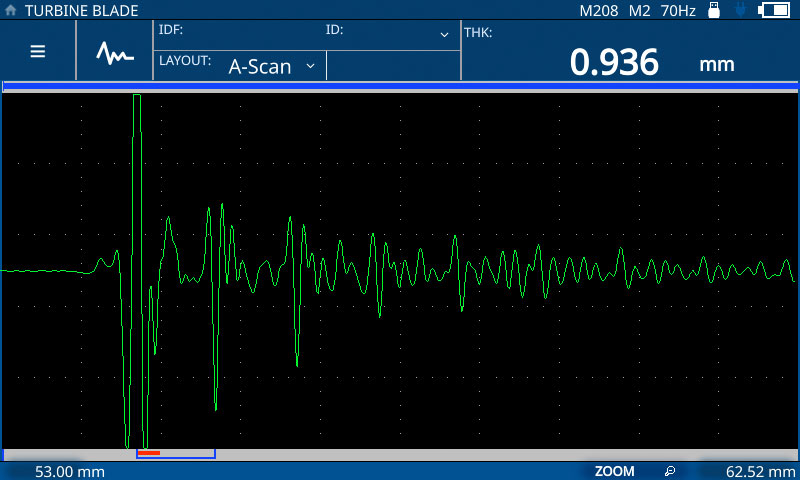

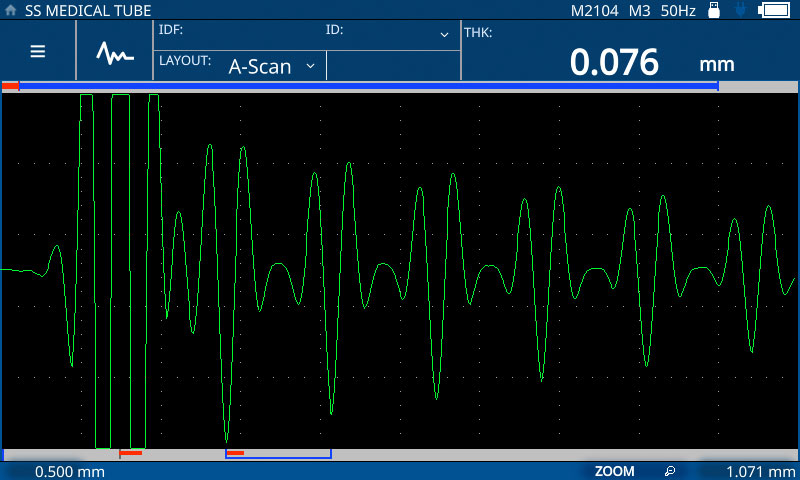

A-Scan

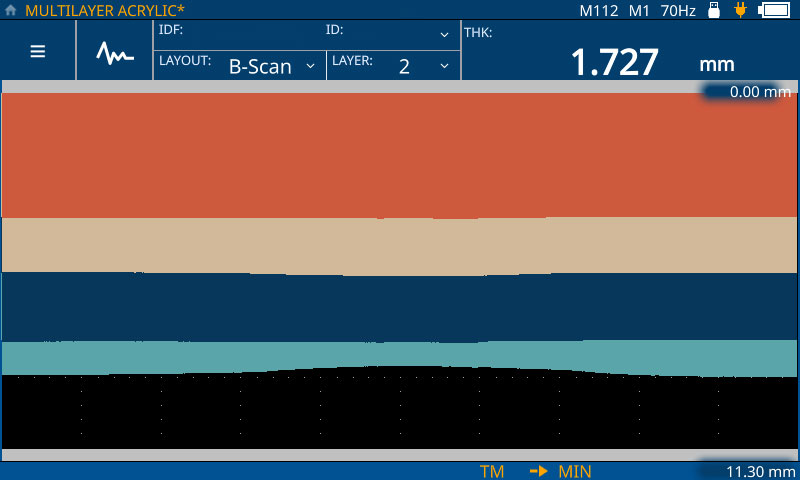

B-Scan

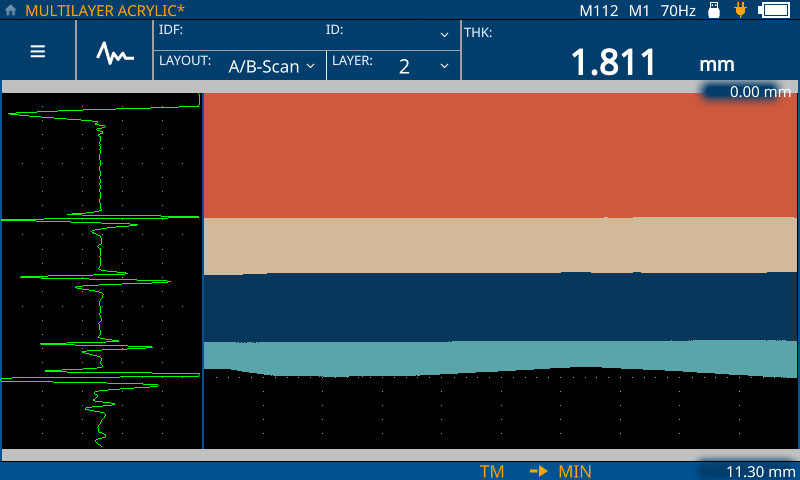

A/B-Scan

Trend

Zoom

Improve Product Quality with Inspection Data Management and Analytics

Collect more inspection data to better control product quality. The PC interface application offers data creation, management, sharing, and analysis tools to empower data-driven decisions on the manufacturing production floor. Monitor thickness trends, spot quality issues, and generate reports to help maintain consistent product quality and improve processes.

- Monitor thickness trend changes: analyze data points in statistics, trendline, and histogram views

- Spot quality issues: see the history of a part or measurement locations across multiple parts in the analytics dashboard

- Assess inspection quality: organize data and application files from multiple gauges in a single storage location

- Generate manufacturing inspection reports in a PDF format for individual components or entire production lines using customizable templates

- Fast, simple data recording: supports data transfer using USB and Wi-Fi® to reduce errors and bias in data collection; data can be exported to Excel for further analysis

Applications

Fast Precision Thickness Gauging for Many Applications

The 72DL PLUS™ instrument can be used as a paint thickness gauge, coating thickness gauge, or material thickness gauge. No matter the application, the gauge delivers reliable, lab-quality measurements at high speed to maximize productivity and throughput on the production floor.

Automotive

Paint thickness gauge for cars and other vehicles

- Accurate automotive paint thickness measurements

- Measure up to 6 paint layers

- Simultaneously display all paint layer measurements at once

Aerospace

- Fast measurements for turbine blade manufacturing

- Turbine blade inspection and repair

- Aircraft window inspection

- Aerospace paint and coatings

- Single and multilayer coating material thickness on composite aircraft

- Measure coatings on composite aircraft radomes

- Aluminum composite panel measurement

General Manufacturing

- Measure thin-walled and small-diameter tubing

- Plastic and metal tubing

- Medical tubing and catheter wall thickness

- Coating thickness gauge for manufacturing

- Single and multilayer coating material thickness measurements

- Waterproof and antireflective coatings

- Dry film thickness

- Thick and thin film thickness measurements

- Plastic thickness gauge for manufacturing

- Multilayer plastic thickness measurement of bottles, trays, and tanks

- Multilayer plastic food containers

- Material thickness gauge for manufacturing

- Multilayer material measurements

- Silicon wafer thickness

- Metal sheet and plate thickness

- Gold foil thickness

- Adhesive tape thickness

- Polypropylene packaging thickness

Choose Your Gauge

Choose the Thickness Gauge Model That Best Suits Your Needs

Choose from standard frequency and high-frequency models with the Multilayer Measurement feature, depending on the application.

Standard frequency model: offers reliable thickness measurements at high speed (2 kHz measurement speeds and a 60 Hz display update for A-scan) using single element transducers with a frequency range of 0.2 to 30 MHz

High-Frequency model: includes all the features of the standard frequency model, as well as up to 125 MHz transducer frequency support for measurement of ultra-thin materials

Multilayer Measurement Feature: simultaneously displays up to six multilayer measurements

| Supported Feature or Mode |

72DL PLUS

Standard Frequency |

72DL PLUS

High Frequency |

| 177.8 mm (7 in.) Touch Screen WVGA Display | X | X |

| 60 Hz Display Update for A-Scan | X | X |

| Measurement Rate up to 2 kHz | X | X |

| Calibration, Gain, and Blank Controls on Frozen Waveforms | X | X |

| Multilayer Measurement | X | X |

| 0.2 to 30 MHz Frequency Range | X | — |

| Up to 125 MHz Frequency Range for Ultra-Thin Materials | — | X |

Choose Your Transducers

The 72DL PLUS thickness gauge is compatible with our single element ultrasonic transducers with frequencies up to 125 MHz:

- 0.2–30 MHz range for the standard frequency and high-frequency models can measure materials at high speed for fast results

- 20–125 MHz range for the High-Frequency model can measure ultra-thin materials

Specifications

72DL PLUS™ Specifications

| Standard Frequency | High Frequency | |

|

Overall Dimensions

(W × H × D) | 238.76 × 172.72 × 86.36 mm (9.4 × 6.8 × 3.4 in.) | |

| Weight | 2.08 kg (4.6 lb) | |

| Power Supply | AC/DC adapter 24 V, or lithium-ion battery 73 Wh | |

| Battery Life | 8 hrs | |

| Battery Storage Temperature | -20°C to 40°C (-4°F to 104°F) | |

| Operating Temperature | -10°C to 50°C (14°F to 122°F) | |

| Display | 177.8 mm (7 in.) WVGA (800 × 480) PCAP touch, refresh rate 60 Hz | |

| Resolution | LOW: 0.1 mm (0.01 in.) | LOW: 25 μm (1 mil=0.001 in.) |

| STD: 0.01 mm (0.001 in.) | STD: 2.5 μm (0.1 mil=.0.0001 in.) | |

| HI: 0.001 mm (0.0001 in.) | HI: 0.25 μm (0.01 mil=0.00001 in.) | |

| Thickness Range (dependent on probe frequency, probe type, and material) | Steel 0.20 mm to 635 mm (0.008–25 in.) | Plastic 0.0127 mm to 25.4 mm (0.0005 in - 1 in) |

| Multilayer Measurements | Up to 6 layers | |

| Measurement Rates | 1–3 layers 2 kHz max | 1–3 layers 1 kHz max |

| 4–6 layers 1 kHz max | 4–6 layers 500 Hz max | |

| Calibration | Single- or two-point automatic calibration; zero offset and/or velocity manual adjustment; single-point calibration from frozen waveform | |

| Display Layouts | A-Scan, B-Scan, A/B-Scan, Trend, Zoom, Template, and A-Scan/Template | |

| Capacity | 2 GB; ~400,000 thickness readings, 20,000 waveforms | |

| Frequency Range | 0.2–30 MHz (-3 dB) | 20–125 MHz (-3 dB) |

| Gain | Automatic or Manual (max 100 dB) | Automatic or Manual (max 80 dB) |

| IP Rating | Designed and tested for IP65: protected against dust and water jets from all directions | |

| Explosive Atmosphere | MIL-STD-810F, Method 511.4, Procedure I | |

| Shock Tested | MIL-STD-810F, Method 516.5, Procedure I, 6 cycles each axis, 15 g, 11 ms half sine | |

| Vibration Tested | MIL-STD-810F, Method 514.5, Procedure I, Annex C, Figure 6, general exposure: 1 hour each axis | |