The annual American Society for Nondestructive Testing conference is one of the world’s largest gatherings of nondestructive testing (NDT) professionals. Over three days, our colleagues from all NDT-associated sectors connect to share their knowledge, experience, methods, and tools. It’s also an exciting occasion to bring to light all the recent advances in inspection tech, which makes it the ideal setting to introduce our latest innovation, the OmniScan X4 flaw detector!

If you’re attending ASNT 2024, you may cross paths with Emilie Peloquin. She’ll be making the rounds in person and on our social media platforms to help introduce the new addition to our OmniScan line. Emilie is not only our Executive Director of Global Advanced NDT Product Support, but also a director of the ASNT Board of Directors.

| Emilie, who started her career as a welder, maintains a close eye on NDT advancements. She uses and shares this knowledge in her various roles: supporting product applications at Evident, helping develop industry codes and standards with ASNT, ASME, API, among others, and spreading awareness about the NDT industry through her podcast, speaking engagements, among other platforms. |

Sarah Williams (left) discusses the new OmniScan X4 with Emilie Peloquin prior to ASNT 2024 in Las Vegas.

Before she headed to Las Vegas for ASNT 2024, I sat down with Emilie to get her firsthand take on the new OmniScan X4 flaw detector.

Be Ready for What’s Next: Stay Ahead of the Curve with the OmniScan X4 Flaw Detector

Sarah: Hi Emilie. Before we get into the OmniScan X4, let’s talk a little about the state of the NDT industry in general and your thoughts leading up to the show.![]()

Emilie: Sure! Most laypeople outside the industry rarely think about or understand nondestructive testing, even though it’s everywhere. NDT keeps all of us safe every day by making sure the integrity of our infrastructure is maintained.

The only time NDT hits the headlines is when it fails; for example, when damage in a pipeline causes a leak. The stakes are high if there is an accident, so industries such as oil and gas have strict regulations in place mandating regular in-service maintenance. Our infrastructure is continuing to age, but the demands on it are not relenting, making failure not a matter of “if,” but “when.”

The onus is on the NDT industry to inspect assets and infrastructure to help ensure their integrity. Detecting damage as early as possible, so it can be dealt with before it reaches the critical stage, is the goal of any asset owner. Catching flaws earlier can save time and costs as repairs are often less complex and expensive, and long costly shutdowns can be avoided.

The OmniScan X4 delivers a range of techniques designed to help detect damage mechanisms in aging infrastructure assets.

New Techniques to Detect the Damage Mechanisms in Aging Assets

Sarah: When you say that oil and gas infrastructure is aging—how old are you talking?

Emilie: Most of these components have been there since the 70s and the industry is still inspecting them in the same way using the same techniques as when they were constructed. But now they’re old and being affected by damage mechanisms that are not necessarily coming from the construction weld. This damage is caused by years of running the component under pressure, heat, and other sources of stress and wear. Damage mechanisms such as HTHA, H2S, and creep damage are now part of the NDT inspection landscape. These flaws are insidious and can be extremely hard to detect. We need to use different techniques and tools to properly discern them, as conventional techniques like UT (ultrasonic testing) are more likely to miss them due to their limitations: limited angles, limited sound beams, etc. You’re just throwing less at it.

Again, without wanting to sound dramatic, for these aging assets, it’s not if it will fail, but when. Having H2S in some components can be manageable, but you need to be able to give the engineers sufficient information about the damage. They can then use that information to assess the remaining life of the component, determine the new pressure level they’ll operate it at, or make repair recommendations to extend the life of the component.

Sarah: The OmniScan X4 is Evident’s newest flaw detector. What are the biggest contributions that it will make in improving the work of NDT inspectors?

Emilie: What the OmniScan X4 brings to the table is multiple ultrasonic technologies and powerful focusing capabilities so the inspector can throw every tool they have at the damage to provide as much data as possible to support their assessment. The last thing an inspector wants is to be unsure of a call they make, and possibly recommend a component’s premature retirement. With the access the OmniScan X4 provides to various techniques, additional beneficial views, and different ways to look at that information within the same working environment, you are far more likely to make the right call. You’re simply stacking the odds in your favor.

Sometimes it’s not only about what the inspector sees, but also how well they can present their findings to the asset owner. Even if the asset owner is inexperienced at interpreting ultrasonic imaging, you want to enable them to clearly visualize and understand the extent of the damage.

I think that’s the main way the OmniScan X4 will help inspectors.

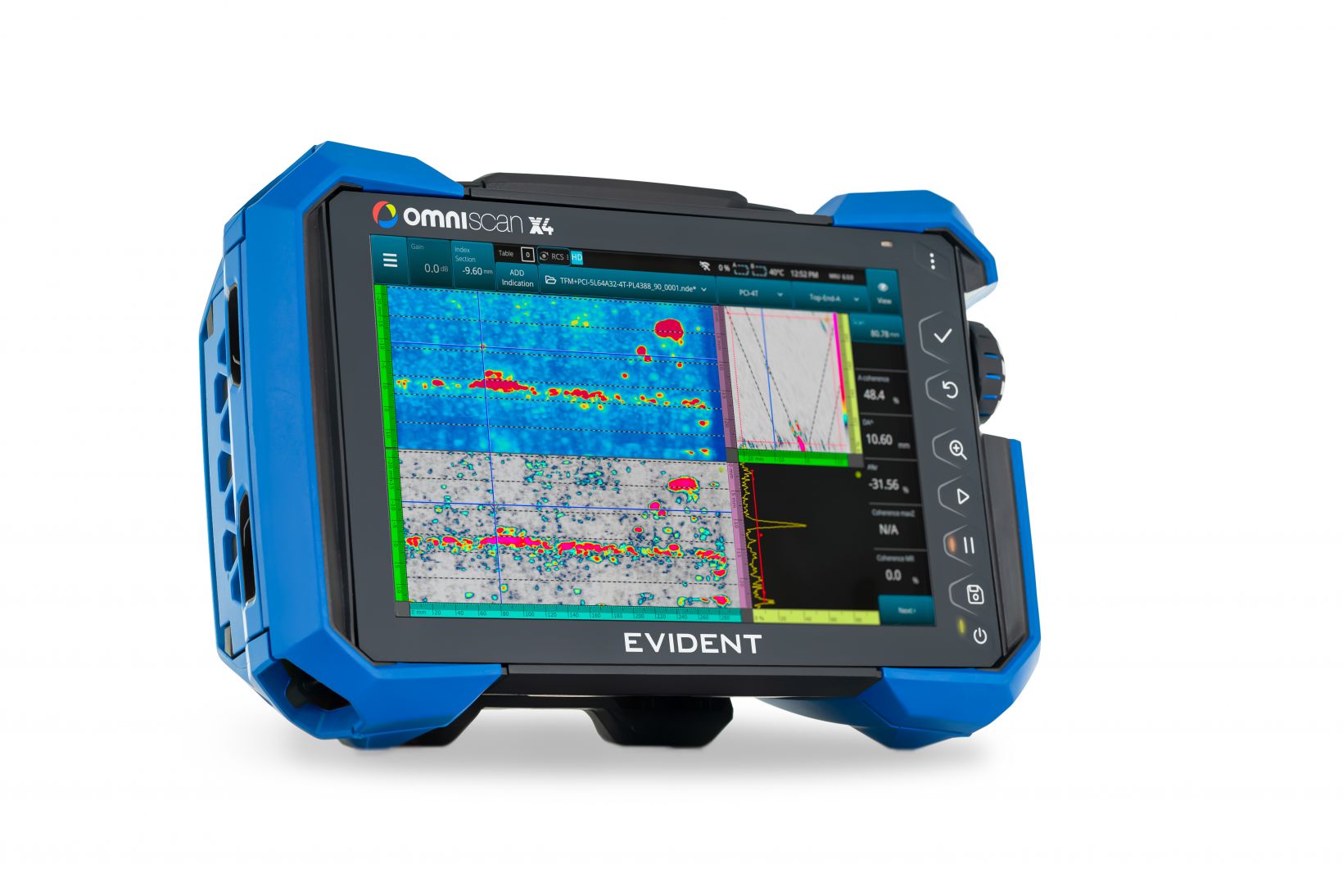

The new OmniScan X4 is an advanced multitechnology flaw detector equipped with TFM, PCI, and PWI inspection capabilities.

The new OmniScan X4 is an advanced multitechnology flaw detector offering high-quality imaging and an array of tools that enable you to detect even hard-to-detect damage mechanisms and measure them with precision. Using all its validation tools, you can decisively assess the severity of flaws and provide irrefutable evidence to the asset owners, so they can be as proactive as possible.

“With access to a variety of techniques, you are far more likely to make the right call.”

Sarah: What are the various validation tools that the OmniScan X4 flaw detector offers inspectors?

Emilie: Every OmniScan X4 model is equipped with Evident’s complete range of ultrasonic testing techniques. We’ve equipped it with the power it needs to perform the complex processing required for imaging techniques such as TFM (total focusing method), PCI (phase coherence imaging), and PWI (plane wave imaging). That means that even if you purchase the basic model, you can perform TFM, PCI, and PWI inspections. Having these techniques in addition to PA (phased array) can be a huge help in making a definitive determination about the extent of certain damage. Again, more tools mean less doubt.

Sarah: What information can these advanced techniques, such as TFM and PCI, provide inspectors that conventional PA or UT cannot?

Emilie: Let’s look at H2S (hydrogen sulfide) damage as an example, since it’s good for showing the comparison. When using conventional PA, it can be challenging to see whether H2S-induced blisters have propagated to the internal surface. And even TFM results may not be conclusive as they are also amplitude-based. With amplitude-based techniques, you may be able to detect hydrogen blistering using a zero-degree inspection, but it can be difficult to determine whether we’re looking at a lamination (which can be perfectly tolerable), or if it’s a stepwise connection reaching the internal surface.

Seeing the full extent of the damage can be a struggle with only one angle in amplitude. If the reflection from the stepwise cracking is too weak to make it back to the probe, it won’t present as a significant indication. On the other hand, PCI uses the phase information to reveal this hidden but essential information. You’ll see a clear diffraction in the data that enables you to easily distinguish whether it’s a lamination or if there is indeed microfissuring reaching the internal surface or creeping toward another blister, which puts the whole component at risk.

Detect Insidious H2S, HTHA, or Creep with Confidence

Sarah: Can you explain to me a bit more why PCI is better at revealing flaws in such detail?

Emilie: PCI is especially sensitive to small defects and crack tips, so you can even easily distinguish each crack in a group, such as colonies of stress corrosion cracking. Though these flaws can have a weak amplitude response with PAUT or TFM, the phase response from their edges is highly coherent so they appear crisp and clear in the PCI results.

That said, amplitude techniques are still very proficient at detecting most common flaws, and utilizing several techniques simply increases your chances of a more precise and confident severity assessment. With the OmniScan X4 series, you choose layout options that display and allow you to compare your TFM and PCI results or four TFM wave sets results simultaneously. Vertical cracks are typically hard-to-detect reflectors, for example, but certain propagation modes, or wave sets, tend to give you a better result. One wave set may only provide a partial view, so additional wave sets can help complete the picture. For a vertical crack, you should be able to get a good image using a self-tandem mode such as the TTT-TT or TT-T wave set, while pulse-echo wave sets such as T-T and TT-TT can be used to detect corner trap echoes and diffraction tips. Choosing to display TFM and PCI results side by side gives you the full picture of amplitude versus phase, so you can benefit from both of their attributes to have more proof to support your call.

Sarah: What do you say to PAUT practitioners who aren’t familiar with these advanced techniques and think they will take a long time to learn to use properly?

Emilie: First off, the scan plan workflow is very intuitive, even for TFM and PCI setups, and now we have a new addition that will help lessen the learning curve for inexperienced users, as well as ease the experience for more seasoned users. With the OmniScan X4, we’ve introduced application presets featuring preprogrammed parameters for several common setups. There are choices for PA and PCI inspections, already containing the required values for our RollerFORM, HydroFORM, and FlexoFORM scanners. This eliminates the need to verify the specs for the scanners and their probes and helps remove the risk of human error affecting the results.

PCI is also easier to set up than you might expect. Being a phase-based technique, no gain calibration is required since amplitude isn’t a factor. There is no gain adjustment during inspection, which prevents signal saturation, helping make sure no flaws are hidden by larger diffractors in proximity. I’m convinced that the ease-of-use of PCI, its clarity and sensitivity to small defects, and the fact that it’s available in every OmniScan X4 model is going to help democratize the technique, making it more accessible for users of every level.

We are also diligent in the support we offer OmniScan X4 owners, and Evident has an extensive network of training partners to help inspectors fully exploit the instrument’s capabilities. If an OmniScan X4 user needs our tech support, our experts are ready and willing to help.

Sarah: Are there other features of the OmniScan X4 that ease the job for inspectors in the field?

Emilie: Absolutely! On a hardware level, it’s a highly portable instrument. When performing in-service maintenance, you may have to squeeze into tight spots or climb up on top of a large component, so the fact that the OmniScan X4 unit is not heavy or cumbersome is a plus. It features the same lightweight yet rugged and field-proven casing as Evident's OmniScan X3 series, even for the fully loaded 64 pulser models.

The OmniScan X4 is a highly portable instrument that can be used by solo inspectors with a variety of scanners, including HydroFORM, RollerFORM, and AxSEAM scanners.

Evident also offers portable scanners, such as the HydroFORM™ scanner for corrosion or RollerFORM™ XL scanner for composites, which you can manipulate with one hand. Even the AxSEAM™ scanner, used mainly for long seams of pipes, is easy to use for solo inspectors. It’s equipped with a control pad, the ScanDeck™ module, that lets you communicate with the OmniScan X4 unit at a distance. So even while you’re using two hands to steer it, you can start and stop the data acquisition, and it has warning lights to let you know when you’re scanning too fast or if coupling between the probe and the part is lost, so you can avoid having to rescan.

Gain Insights and Eliminate Inefficiency with Twin TFM and PCI

Sarah: With the OmniScan X4 you can use both TFM and PCI and use two probes to scan welds in one pass. Can you tell us a little more about that?

Emilie: Yes, an added bonus for setups using the AxSEAM scanner and an OmniScan X4 unit is the efficiency boost that comes with twin TFM and PCI. This is a new feature that enables you to acquire data from both sides of the weld with two probes and produce TFM and PCI results, which you can display simultaneously. This makes TFM and PCI more attractive options to support pipeline weld inspection.

The OmniScan X4’s twin TFM and PCI enables the acquisition of data from both sides of the weld and produces TFM and PCI results simultaneously.

In the past, the slower inspection rates associated with processing heavy techniques like TFM may have deterred some users from wanting to add more than one probe, but with the OmniScan line, we’ve been continually enhancing our TFM and PCI processing speed. According to our testing, we can now confidently say that depending on configuration, the OmniScan X4 series’ TFM speed is up to three times faster than its predecessor.

Sarah: Have there been any enhancements in terms of data storage?

Emilie: Inspection technicians can also work longer gathering data without stopping since all OmniScan X4 models have a 1 terabyte solid-state drive to store your acquisition files. And it’s also faster in terms of the software’s reactivity. The refresh rate, for example, as you scroll through the scan results or when you move the measurement cursors, it’s nearly instantaneous.

Speed and efficiency are important factors in being proactive. Any delays in completing an inspection have an impact on the asset owner’s ability to take action to repair a damaged component before it gets too critical. This can have a big impact on the length of the downtime for the component, and longer shutdowns equal more money. Enabling the inspector to move more quickly, and transport, set up, and operate their equipment with more ease and agility is contributing to them getting their job done faster.

Sarah: Would you say that the use of the OmniScan X4 is more efficient than other NDT methods?

Emilie: In NDT, applications and configurations vary so drastically that no “one method” alone is a winner. They all should play together as a team. The efficiency of a method also depends a lot on the inspection parameters. It may help to give you a hypothetical example from pipeline construction, comparing PAUT to RT (radiographic testing), which are similar methods in that they are both used to examine the volume of a weld or a part.

When a pipeline is being built, the welder’s work is inspected to ensure the quality of the weld. If we compare PAUT with RT, which is a commonly used method for new fabrication welds, there could be some clear advantages in my view. The inspection tech operating the OmniScan X4 unit can be next to the welder, and they can inspect the weld right after its completion, giving immediate feedback on the quality. For example, if there is a lack of fusion, the welder can use that information to adjust their technique, paying closer attention to or adjusting the settings on their welder to avoid a lack of fusion in the next weld.

The equipment to perform RT is often heavy and bulky, but more than that, a safety radiation barricade around the perimeter is required. This means that construction has to stop during the RT inspection, so it’s often performed at night or during shift changes when no one is around. With gamma ray cameras, the RT techs also need to develop the film in a dark room, so it takes more time to get the results. Either way, any flaws identified are dealt with as a post-repair.

If a repair is identified with RT, either the construction crew will dig it completely out, which could result in good weld being cut out, or they use ultrasonic testing to find the actual depth of the flaw. If a repair is found with PAUT, the results show you the depth from each surface, including height and length measurements within the weld in real-time.

This situation shows how having immediate, easy-to-characterize results could enable proactive and cost-saving action. The welder adapting their technique can use the information to improve the quality of subsequent welds, avoiding the need for additional repairs. This offers an immediate benefit for the pipeline construction contractor and the asset owner down the line.

Sarah: That makes perfect sense! So lastly, if you had to narrow it down to one thing, what would you say differentiates the OmniScan X4 series from all other flaw detectors?

Emilie: What makes the OmniScan X4 so different is that it gets smarter over time. Evident continually develops the flaw detector’s onboard software, enhancing it and adding new features that target specific needs of the industry. We listen to customers’ feedback about what they need to make their job easier or more efficient, and then our R&D works hard to find a way to make their wish list a reality. Every improvement we make is then provided for free to OmniScan X4 users through quarterly software updates. You don’t get that anywhere else.

A big thank you to Emilie for taking the time to sit down with me! If you are heading to ASNT 2024, Emilie and the Evident Team will be waiting for you at booth #600, ready to give you a firsthand look at the new OmniScan X4. Check out our ASNT presentation and demo schedule here.

Related Content

Advantageous Applications for Phase Coherence Imaging

Investments in Quality Training and Equipment—Concocting a Recipe for Inspection Success