7.2 Shafts, Forgings, and Bolts

Shafts and bolts have in common a long cylindrical geometry that is usually suitable for ultrasonic testing. Since cracks tend to occur perpendicular to the ends, testing is typically performed with straight beam transducers, from both ends in the case of long shafts. In both cases the typical procedure is to identify the echo from the far end and look for echoes appearing ahead of that peak as the transducer is moved around the face of the part.

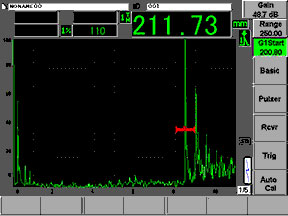

In the case of bolt inspection, the operator must notes any thread echoes that are generated by the part and look for crack indications that appear against that background. Note that the surface of the bolt must be sufficiently flat to permit proper sound coupling, thus bolts with rounded or hex-type heads may not be inspectable. Bridge hanger pins represent a related application, and they can usually be testing for shearing with a similar straight beam test. The example below shows detection of a small notch representing a crack originating in the threads of a 212 mm (8.35”), using a 10 MHz contact transducer. The waveform at left shows the backwall echo from an intact bolt, and the waveform at right shows the indication from the reference notch in the “cracked” sample.

|  |

| Good bolt, gate on backwall echo | Indication from reference notch |

While inspection of smooth shafts, even very long ones, is usually straightforward, shafts whose diameter changes in steps require special consideration. Insets and large-to-small diameter changes will produce predictable echoes at screen locations corresponding to their distance, and sometimes additional mode-converted echoes caused by beam spreading and sidewall bounces will be present. The inspector must note the position of all of these fixed indications and then look for localized echoes that appear against that background. He or she must also be aware of dead zones not reached by the sound beam due to the “shadow” of diameter changes, although frequently testing from both ends eliminates this problem. In some cases involving stepped diameters, low angle longitudinal wave wedges are used to aim the sound beam at a specific point of interest such as a corner that is known to be susceptible to cracking.

Forgings of all sizes can be inspected for internal flaws such as piping, laminar cracking, and ruptures. Testing is commonly done with straight beam transducers, often from two directions to permit detection of discontinuities aligned both parallel with and perpendicular to the surface of the part. Surface breaking cracks are most easily detected through eddy current inspection as a supplement to ultrasonic testing.