2.1 What is Ultrasound?

Sound waves, which are all around us, are simply organized mechanical vibrations traveling through a medium, which may be a solid, a liquid, or a gas. This applies to both the everyday sounds that we hear and the ultrasound used for flaw detection. Sound waves will travel through a given medium at a specific speed or velocity, in a predictable direction, and when they encounter a boundary with a different medium they will be reflected or transmitted according to simple rules. This is the principle of physics that underlies ultrasonic flaw detection. In short, ultrasonic waves will reflect from cracks or other discontinuities in a test piece, so by monitoring the pattern of echoes in a part a trained operator can identify and locate hidden internal flaws.

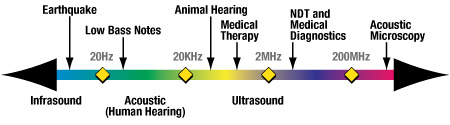

All sound waves oscillate at a specific frequency, or number of vibrations or cycles per second, which we experience as pitch in the familiar range of audible sound. Human hearing extends to a maximum frequency of about 20,000 cycles per second (20 KHz), while the majority of ultrasonic flaw detection applications utilize frequencies between 500,000 and 10,000,000 cycles per second (500 KHz to 10 MHz). At frequencies in the megahertz range, sound energy does not travel efficiently through air or other gasses, but it travels freely through most liquids and common engineering materials like most metals, plastics, ceramics, and composites. Sound waves in the ultrasonic range are much more directional than audible sound, and because of their short wavelengths they are also far more sensitive to small reflectors that lie in their path.

The speed of a sound wave varies depending on the medium through which it is traveling, affected by the medium's density and elastic properties. Different types of sound waves (see Modes of Propagation, Section 2.3) will travel at different velocities.