TOFD Solution

Overview

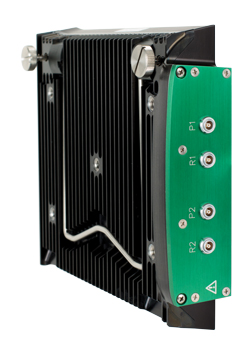

The Olympus OmniScan MX2 with the UT2 module and the OmniScan® SX are powerful yet affordable solutions for TOFD inspection. Representing the latest developments in software and hardware, the OmniScan SX and the UT2 module for the OmniScan MX2 are designed to make weld inspection using the TOFD technique fast and easy. Numerous performance enhancements and a leading-class signal-to-noise ratio provide you with optimum data quality for TOFD inspection.

Key Improvements

When combined, these features offer you a faster and simpler setup, easier results interpretation, and more accurate defect sizing for an overall increase in productivity. |  |

Lateral Wave Straightening

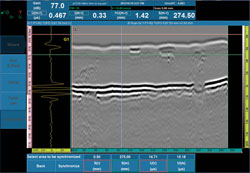

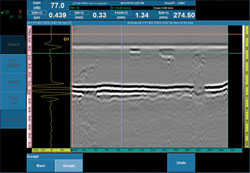

The lateral wave straightening function has been optimized so that the readability of TOFD results is improved. A straighter lateral wave also enables more precise depth evaluation and flaw sizing.

Raw TOFD Data |  TOFD data after lateral wave straightening is applied. |

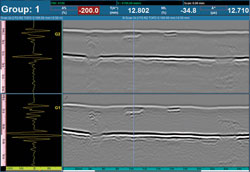

Multi-TOFD Layouts (OmniScan MX2 only)

The new Multi-TOFD layout, offered in the latest OmniScan® MXU software, can display more than one group at a time. This enables you to easily position and size flaw indications by visual correlation between groups.

OmniPC Analysis Software

All of these improved software capabilities have also been incorporated into the OmniPC™ software. This gives you the flexibility to analyze data on a computer, while the OmniScan unit is redeployed to the next data acquisition job.

Dedicated Scanners and Accessories

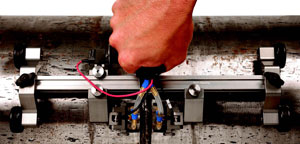

HST-Lite TOFD ScannerThe HST-Lite scanner is an ideal tool for performing cost-effective, one-channel TOFD inspection with consistent and reliable data quality. The combination of magnetic wheels and spring-loaded probe holders offer the stability required to perform high-quality, one-line inspections. The scanner can be operated with one hand, and it maintains a firm hold on ferromagnetic surfaces even when held upside-down. |  |

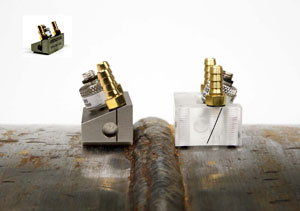

Stainless Steel TOFD WedgesOlympus offers an HST-Lite scanner kit that comes standard with stainless steel TOFD wedges. For many applications, stainless steel wedges are a better option than common Rexolite wedges as they offer several advantages:

These wedges are compatible with the Olympus line of high-performance TOFD transducers (ST1 case type). |  The approach of the stainless steel wedge (on the left) is 3 mm shorter than the Rexolite wedge for better weld coverage |

TOFD Inspection of Small PipesDesigned specifically for use with the COBRA® pipe scanner, an additional line of TOFD wedges is available for small-diameter-pipe weld inspections. These wedges can be fitted with 3 mm element-diameter transducers to inspect pipes measuring from 1 in. to 4.5 in. OD. Olympus ST1 wedges are available in various refracted longitudinal angles, and they can be ordered for specific diameters or in a kit covering the complete diameter range. |  The COBRA small-diameter pipe scanner can perform TOFD inspections with the appropriate wedges, cables, and transducers. |

Specifications

Ordering Information

| Instrument | ||

| Part Number | Item Number | Description |

| OMNI2-P2-UT-2C | U8100132 | OmniScan MX2 and 2-channel UT2 module package |

| OMNISX-UT | U8779743 | OmniScan SX and 1 UT channel |

| OMNISX-PA1664PR | U8779744 | OmniScan SX phased array 16:64 with 1 UT channel |

| OMNIPC-A | U8775269 | OmniPC software |

| Scanner Packages | ||

| 1 in. to 4.5 in. OD — Single-group TOFD weld inspection with COBRA scanner | ||

| Part Number | Item Number | Description |

| COBRA | U8750053 | Small pipe scanner kit with encoder |

| COBRA-A-ST1-70L | U8701348 | 70° L-wave wedge kit including 2 flat and 9 pairs of curved TOFD wedges for pipes of 1.05 in. to 4.5 in. OD |

| COBRA-A-ST1-80L | U8710172 | 80° L-wave wedge kit including 2 flat and 9 pairs of curved TOFD wedges for pipes of 1.05 in. to 4.5 in. OD |

| COBRA-SP-BASIC | U8775166 | Basic spare parts kit |

| COBRA-SP-FULL | U8775188 | Basic spare parts kit, plus links and encoder assembly |

| C563-SM | U8435028 | Centrascan composite transducer, 10 MHz, 0.125 in. (3 mm) diameter with straight Microdot connector |

| V564-SM | U8474029 | Videoscan transducer, 15 MHz, 0.125 in. (3 mm) element diameter with straight Microdot connector |

| C174-LM-UDOT90-3M | U8779694 | Cable LEMO-00 male 180 to Microdot 90°, 3 m, coaxial RG174 |

| WTR-SPRAYER-4L | U8775153 | 4 L manual water pump with irrigation tubes and fittings |

| 4.5 in. OD up to flat — Single-group TOFD weld inspection with HST-Lite scanner | ||

| Part Number | Item Number | Description |

| HST-Lite-Kit01 | U8750062 |

Manual TOFD scanner package. Includes: scanner with two spring-loaded probe holders for 31.75 mm wide TOFD wedges, four magnetic wheels and OmniScan-compatible encoder with 5 m long cable, irrigation tubing, and protective cable conduit. The scanner has a 345 mm long frame bar.

The package also includes: two 5 m LEMO-00 to Microdot probe cables, two 10 MHz, 3 mm (C563-SM) and two 5 MHz, 6 mm (C543-SM) composite TOFD transducers with Microdot connector, 2 each of 45°, 60°, and 70° stainless steel TOFD wedges with irrigation and scanner holes (ST1-45L-IHS, ST1-60L-IHS, and ST1-70L-IHS), and one carrying case. |

| WTR-SPRAYER-8L | U8775001 | 8 L manual water pump with irrigation tubes and fittings. |

| 4.5 in. OD up to flat — Multi-Group TOFD weld inspection with HSMT-Compact or HSMT-Flex scanner | ||

| Part Number | Item Number | Description |

| HSMT-COMPACT | U8750024 | Manual scanner with four spring-loaded probe holders, four magnetic wheels, and OmniScan-compatible encoder with 5 m long cable and irrigation tubing. Includes frame bars of three different lengths (250 mm, 450 mm, and 650 mm). |

| 60BA0131 | U8775093 |

0.3 m of divisible cable conduit with 24.2 mm ID.

Well-suited for 2 × PA, 4 × conventional UT, irrigation tube, and encoder cable. Unit: 0.3 m (1 ft) long. |

| C563-SM | U8435028 | Centrascan composite transducer, 10 MHz, 0.125 in. (3 mm) element diameter with straight Microdot connector |

| C543-SM | U8435020 | Centrascan composite transducer, 5 MHz, 0.25 in. (6 mm) element diameter with straight Microdot connector |

Specifications

| Pulser | |

| Voltage | 95 V, 175 V, and 340 V |

| Pulse Width | Adjustable from 30 ns to 1,000 ns; resolution of 2.5 ns |

| Pulse Shape | Negative square wave |

| Output Impedance | <30 Ω |

| Receiver | |

| Gain | 0 dB to 120 dB maximum input signal 34.5 Vp-p (full-screen height) |

| Input Impedance |

64 Ω in pulse-echo mode

51 Ω in pulse-receive mode |

| System Bandwidth | 0.26 MHz to 27 MHz (−3 dB) |