Quality assurance is considered essential in the development and production process of automotive vehicles, as even small defects in components can cause serious accidents. Industrial borescopes are commonly used to inspect the quality of core automotive components, such as engines. They contribute extensively to quality improvement in the automotive industry.

In fact, the rapid increase in demand for electric vehicles, or EVs, has expanded the area of borescope inspection needs. Considering that the EV parts to be inspected are different from those for conventional internal combustion engines, the borescope inspection methods are also slightly different. One example is the inspection of inverters—a key component of electric vehicles and other modern cars.

This best practice guide offers tips to drive efficiency in EV inverter inspection, highlighting key considerations for selecting a suitable borescope for the task.

What Is an Inverter in an Electric Vehicle?

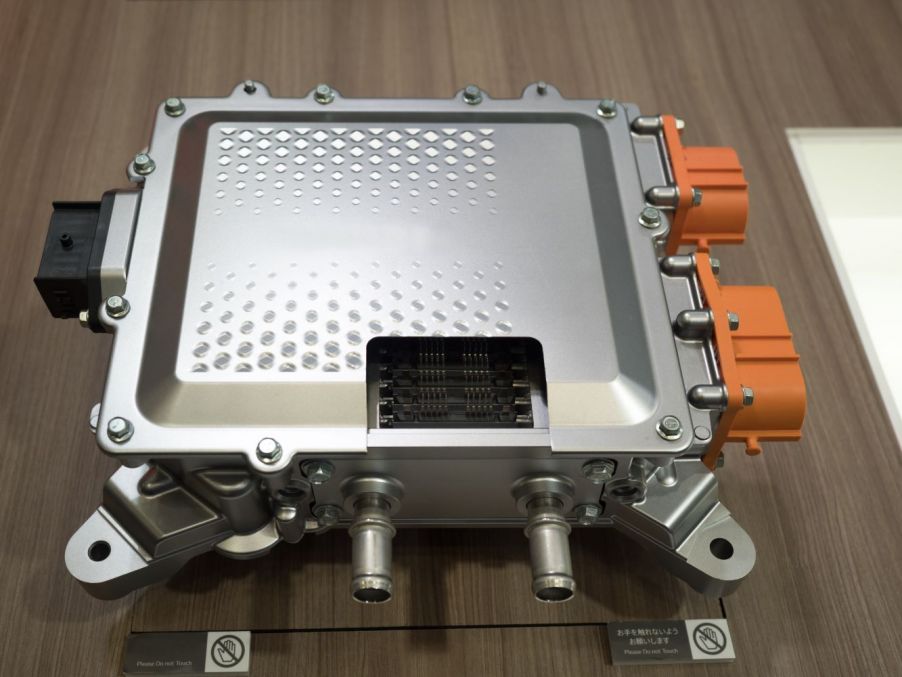

Broadly speaking, an inverter is an electronic device that converts direct current (DC) power to alternating current (AC) power. In an electric or hybrid vehicle, the inverter supplies and controls electricity to a traction motor to drive the wheels.

The inverter is responsible for controlling the AC frequency and adjusting the motor speed and torque. Fine control of this adjustment enables efficient drive, enhancing ride comfort. With the expansion of electric vehicles in the future, demand for inverters is expected to increase.

Example of an inverter for an electric vehicle.

Why Is Borescope Inspection Required for EV Inverter Assembly?

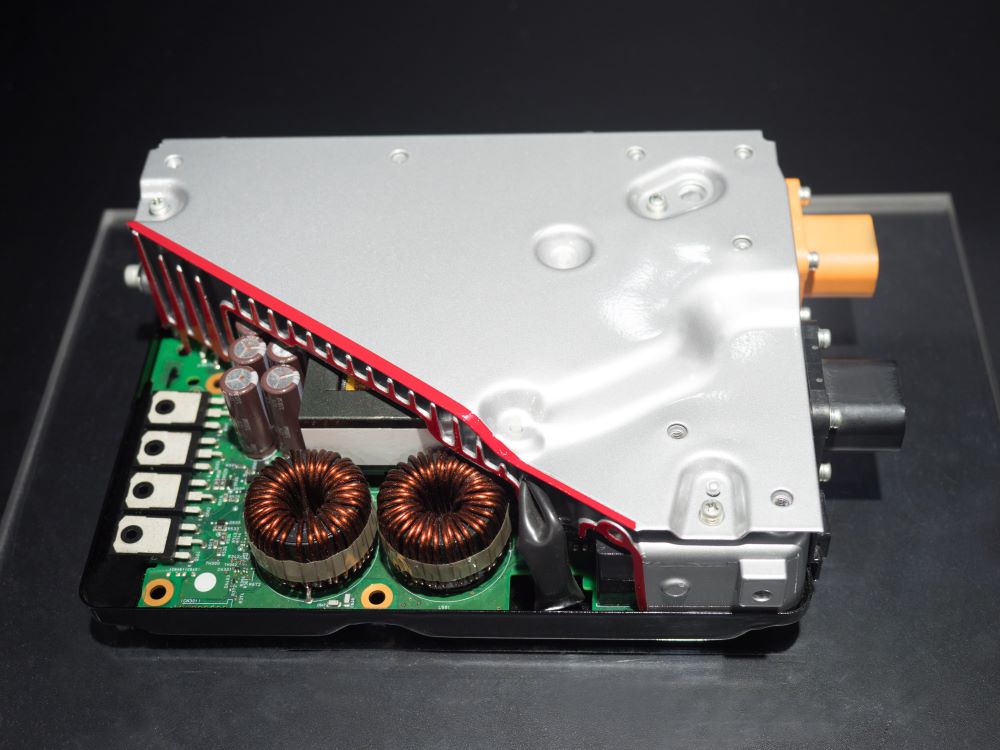

After an inverter is assembled, a borescope is used to inspect the soldered parts of the board. Specifically, a borescope is used to check proper soldering and the absence of foreign matter or other adhesions. Any abnormality here will adversely affect the speed control function of the car and other functions. Visual inspection of the soldering is also performed before assembly. The challenge is that the parts to be inspected are small, so defects may be overlooked. Therefore, it’s important to perform a detailed borescope examination after assembly.

Electronic circuit board.

Since inverters are critical components of electric vehicles, there are many cases where all inverters are inspected. In these cases, inspections are conducted once every several tens of seconds in the manufacturing process. When a defect is found, it is common to ask the quality department for a detailed investigation.

When the manufacturing department conducts a full inspection in this manner, the time spent on the inspection of each part is limited. This can lead to cases where defects are overlooked. It is important to prevent oversights during inspections in the manufacturing process to maintain the quality of inverters.

Challenges of Inspecting EV Inventers

In the inspection of EV inverters, a small-diameter video borescope is generally required because of the narrow insertion opening to reach the part to be inspected. An inspector inserts the scope through a small hole in the board to reach a position where the soldered area can be observed. The scope must be able to reach the inspection point in a short time through a narrow insertion opening. This requires fine control of the scope.

Another challenge is lighting. Despite the narrow opening, the space inside the board is large, requiring a certain amount of light from the scope for proper inspection. On top of that, it is necessary to adjust the light intensity appropriately since the soldering area tends to create halation when the scope reaches a close distance.

To perform remote visual inspection of an EV inverter properly, quickly, and efficiently, make sure to use a video borescope with ability to finely control the scope and adjust the light intensity according to the distance to the object being inspected.

Selecting the Right Video Borescope for EV Inverter Inspection

The IPLEX™ TX II video borescope has been evaluated by inverter-related companies for its ability to effectively perform these inspections. Here's why they like it so much:

1. Insertion performance

The IPLEX TX II video borescope has an ultra-thin flexible scope with an outer diameter of 2.0 mm, enabling insertion through the narrow insertion slot of the inverter board without issues. We designed the borescope with a primary focus on improving insertion—a key factor to help ensure that the scope reaches the point to be inspected in a short time after insertion.

Ultra-thin borescopes have less space in their internal structure, limiting the tip curvature method to two directions—up and down. In the past, there were cases where the articulation section was damaged during inspection when the scope was forcibly pushed in with loads applied from both sides of the curved part.

The IPLEX TX II video borescope has an improved insertion tube structure that makes the scope distal end flexible enough to bend in all directions. In addition, the short length of the distal end achieves outstanding maneuverability. These features give the IPLEX TX II borescope high insertion performance for EV inverter inspections.

IPLEX TX II video borescope features high insertion performance in narrow spaces.

2. Lighting control

The IPLEX TX II video borescope also has a feature for adjusting light intensity—the second key factor for efficient EV inverter inspection. The borescope is equipped with Scene Mode, a function that lets you switch between standard and customized settings tailored to inverter inspections.

Consider how it works in the following example. An inspector sets the brightness level suitable for observing a large space and the brightness level suitable for observing soldering details in close distance, respectively. With one touch of a button, they can instantly switch the brightness level according to the inspection location. This reduces the time required for inspection.

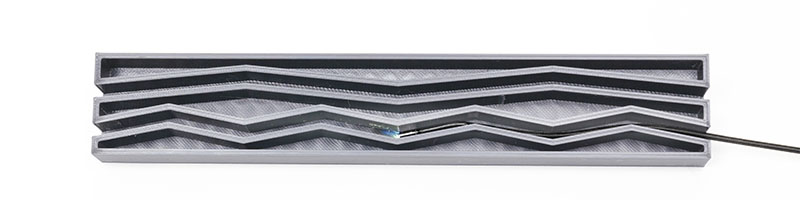

Quickly switch the brightness level according to the inspection location using Scene Mode on the IPLEX TX II video borescope.

3. Wide viewing angle

In addition, the IPLEX TX II video borescope has a viewing angle of 120 degrees. In general, small-diameter borescopes have a narrow viewing angle of 60 to 90 degrees and can observe only a limited area at a time. The IPLEX TX II borescope, with its 120-degree viewing angle, can observe a wide area at once—another factor that helps reduce inspection time.

With a 120-degree viewing angle, the IPLEX TX II video borescope can observe a wide area at once.

Driving Efficiency in Electric Vehicle Inverter Inspection

By driving efficiencies, these remote visual inspection capabilities make the IPLEX TX II video borescope an asset in EV inverter inspection. If you encounter any challenges with borescope inspections related to automotive parts, such as inverters and e-axle cooling furnaces and gears, reach out to our remote visual inspection team! We’re happy to find solutions suitable for your inspection needs.

Related Content

Brochure: IPLEX TX II Videoscope

Video: Better Imaging in Small Spaces with the IPLEX TX II Videoscope

Visual Inspection of Part Defects: Methods, Challenges, and Opportunities