In der schnelllebigen Welt der Automobilherstellung spielt jedes Bauteil eine entscheidende Rolle, um die optimale Leistung, Haltbarkeit und Sicherheit von Fahrzeugen zu gewährleisten. Einer der wichtigsten Werkstoffe für Komponenten bei der Automobilherstellung ist Aluminium. Aluminium ist für sein geringes Gewicht und seine Festigkeit bekannt und wird für die Herstellung von Fahrzeugen verwendet, die leichter, sicherer und kraftstoffsparender sind.

Darüber hinaus ist Aluminium vielseitig einsetzbar. Es ist in einer Reihe von Legierungen erhältlich, die einzigartige mechanische Eigenschaften, wie gute Formbarkeit und ein gutes Verhältnis von Festigkeit zu Gewicht bieten. Aufgrund spezifischer Eigenschaften eignen sich bestimmte Aluminiumlegierungen für verschiedene Fahrzeugkomponenten, sodass im gesamten Fahrzeug verschiedene Legierungen verwendet werden, um die Leistung zu optimieren.

Zudem bieten die richtigen Oberflächenveredelung und Beschichtungen den Aluminium-Autoteilen eine zusätzliche Leistungs- und Schutzschicht. Die richtige Oberflächentechnik für Aluminiumteile kann die Ästhetik verbessern, vor Korrosion, Verschleiß und anderen Umwelteinflüssen schützen oder eine bessere Formbarkeit gewährleisten.

Bezüglich dieser Faktoren hängt die Leistung des Fahrzeugs von der Verwendung des richtigen Materials und der richtigen Beschichtung für das richtige Teil ab. Während die Erstausrüster (OEMs) einen strengen Qualitätsprozess einhalten, müssen Automobilhersteller die Integrität der von den OEM-Lieferanten eingehenden Materialien bestätigen, um die Qualitätskontrolle und -sicherung zu gewährleisten. Hierzu gehört die Überprüfung der Beschichtungsdicke von OEM-Autoteilen aus Aluminium.

Im Folgenden werden die verschiedenen Arten von Aluminiumoberflächen und -beschichtungen, die in der Automobilindustrie verwendet werden, genannt und ihre wirtschaftlichen und physikalischen Vorteile hervorgehoben. Zudem erfahren Sie mehr über ein effizientes Gerät zur Qualitätskontrolle für die Messung und Analyse der Beschichtungsdicke von Aluminium.

4 Arten von Aluminiumoberflächen und -beschichtungen für Automobilkomponenten

Eine Vielzahl von Aluminium-Oberflächenbehandlungen und -beschichtungsverfahren werden für Automobilkomponenten und -teile verwendet. Diese sind:

1. Eloxieren

Das Eloxieren ist eine häufig verwendete Oberflächentechnik für OEM-Autoteile aus Aluminium. Bei diesem Verfahren wird auf der Oberfläche eine Oxidschicht erzeugt. Diese Schicht verbessert die Korrosionsbeständigkeit und ermöglicht Farboptionen. Darüber hinaus bietet eloxiertes Aluminium Haltbarkeit, erhöhte Härte und hervorragende Hafteigenschaften. Aufgrund dieser Eigenschaften eignet es sich für Karosserieteile, Räder und andere sichtbare Komponenten.

2. Chromatfreie Konversionsbeschichtungen

Chromfreie Konversionsbeschichtungen bilden eine Schutzschicht auf Aluminiumoberflächen und erhöhen so deren Korrosionsbeständigkeit. Diese Beschichtungen bieten eine ausgezeichnete Haftung für nachfolgende Farbaufträge. Sie werden häufig für komplexe Anwendungen, wie für Motorkomponenten und Luft- und Raumfahrtteile, eingesetzt.

Die Ti/Zr-Beschichtung (eine Beschichtung auf der Basis von Titan und Zirkonium) ist eines der bekanntesten Beispiele. Es wird durch Aufsprühen eines chemischen Mittels für eine Ti/Zr-Behandlung und anschließendes Abspülen und Trocknen hergestellt. Viele Automobilhersteller wenden die Ti/Zr-Behandlung an, da sie die Haltbarkeit der Bindung von Aluminiummaterialien für Fahrzeuge verbessert.

3. Pulverbeschichten

Das Pulverbeschichten ist ein Beschichtungsverfahren, bei dem ein trockenes Pulver auf die Oberfläche aufgetragen wird, das anschließend zu einer dekorativen Schutzschicht aushärtet. Dieses Verfahren bietet außergewöhnliche Haltbarkeit, Chemikalienbeständigkeit und eine breite Palette von Farboptionen. Pulverbeschichtete Aluminiumteile sind in verschiedenen Bereichen zu finden, wie bei Fahrwerkskomponenten und Innenverkleidungen.

4. Elektroplattieren

Beim Elektroplattieren wird mithilfe einer Elektrolysezelle eine Metallschicht auf die Aluminiumoberfläche aufgebracht. Mit dieser Technik wird die Korrosionsbeständigkeit verbessert, die Oberfläche wird glatt und dekorative Effekte können erreicht werden. Die behandelten Aluminiumteile werden häufig für Außenverkleidungen und dekorative Zwecke verwendet.

Das Streben nach leichteren Elektrofahrzeugen hat zu Fortschritten in der Beschichtungstechnologie geführt. Die Bemührungen in der Forschung und Entwicklung konzentrierten sich auf die Entwicklung von Beschichtungen mit verbesserter Korrosionsbeständigkeit, Haltbarkeit und geringerem Gewicht.

Zu diesen Fortschritten gehören Nanobeschichtungen, Dünnfilmbeschichtungen und fortschrittliche Verbundstoffwerkstoffbeschichtungen, die einen verbesserten Schutz bei gleichzeitiger Gewichtsreduzierung bieten können. Diese Innovationen werden dem Ziel gerecht, das Gesamtgewicht des Fahrzeugs zu reduzieren und gleichzeitig optimale Leistung und Schutz zu bieten.

Es kommt auf die Qualität an: Dickenmessung der Beschichtung mittels RFA – von Nanometer bis Mikrometer

Für Automobilingenieure und -hersteller ist es von entscheidender Bedeutung, eine gleichbleibende Qualität und die Einhaltung von Spezifikationen zu gewährleisten. Ein wichtiger Aspekt bei der Qualitätskontrolle ist die genaue Messung der Dicke von Oberflächenbeschichtungen.

In diesem Zusammenhang erweist sich die Röntgenfluoreszenzanalyse (RFA) als zuverlässige und effiziente Lösung, selbst für Proben mit komplexer Geometrie. Die RFA ist ein zerstörungsfreies Analyseverfahren, das die Elementzusammensetzung von Materialien misst. Außerdem lässt sich damit die Dicke von Beschichtungen auf Aluminiumoberflächen präzise bestimmen, ohne dabei das Teil zu beschädigen.

Technische Fachkraft mit einem RFA-Handanalysator bei einer Beschichtungsanalyse.

Die RFA ist eine bekannte Technik mit mehreren Vorteilen für die Messung der Beschichtungsdicke:

Zerstörungsfreie Prüfung: Mithilfe der RFA-Technologie lässt sich die Beschichtungsdicke messen, ohne die Integrität und Nutzbarkeit der OEM-Aluminiumteile zu beeinträchtigen.

Genauigkeit und Präzision: RFA-Analysatoren ermöglichen hochpräzise und wiederholbare Dickenmessungen von Beschichtungen und verringern so das Risiko von Abweichungen von den Spezifikationen.

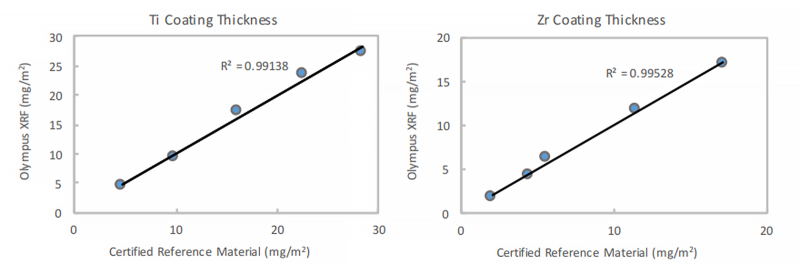

| Beschichtungsdicke | Beschichtungsdicke | ||

|---|---|---|---|

| Labor | RFA | Labor | RFA |

| 4,74 | 4,5262 | 1,94 | 1,6535 |

| 9,87 | 9,4366 | 4,47 | 4,1885 |

| 16,13 | 17,075 | 5,61 | 6,2165 |

| 22,67 | 23,5199 | 11,51 | 11,7935 |

| 28,36 | 27,2368 | 17,19 | 16,8635 |

Die obigen Daten zeigen eine ausgezeichnete Korrelation zwischen den Ergebnissen, die mit einem Vanta RFA-Handanalysator und den Referenzmaterialien für die Dicke der beiden Beschichtungen Titan (Ti) und Zirkonium (Zr) erzielt wurden.

Zeit- und Kosteneffizienz: Die RFA-Technologie ermöglicht schnelle Messungen, minimiert Ausfallzeiten und erhöht die Produktivität. Es macht zerstörende Prüfungen oder eine komplexe Probenvorbereitung überflüssig, was zu Kosteneinsparungen führt.

Vielseitigkeit: RFA-Analysatoren können eine Vielzahl von Beschichtungen messen, wie Eloxal-Beschichtungen, Konversionsbeschichtungen u.a., sodass sie für verschiedene Anwendungen in der Automobilindustrie geeignet sind.

Im folgenden Video ist zu sehen, wie die RFA zur Qualitätssicherung von Beschichtungen beiträgt:

Einführung von Inline-RFA bei der Fahrzeugherstellung für Qualität 4.0

Manchmal ist eine präzise Kontrolle der Beschichtungsdicke im Nanobereich erforderlich (ein Nanometer oder nm entspricht einem Millionstel Millimeter). Bei der Dickenmessung im Nanobereich ist die Konsistenz des Messverfahrens wichtig. Eine manuelle Messung kann nicht immer den optimalen Ablauf gewährleisten.

Aus diesem Grund bieten wir ein automatisiertes Inline-System an, das den Praktiken der Qualität 4.0 entspricht. Ein Roboterarm mit integriertem Inline-RFA-Analysator kann Messpunkte in Echtzeit analysieren und so eine 100%-ige Qualitätskontrolle der Oberflächenbehandlung gewährleisten.

Für eine zuverlässige Qualität von Beschichtungen für Aluminium-Fahrzeug-Komponenten

In der sich kontinuierlich weiterentwickelnden Automobilindustrie sind Oberflächenveredelungen und -beschichtungen unverzichtbar, um die Leistung, den Schutz und die Optik von OEM-Aluminiumteilen zu verbessern. Eloxieren, Chromatieren, Pulverbeschichten, Elektroplattieren und organische Beschichtungen dienen alle unterschiedlichen Zwecken und unterstützen die allgemeinen Haltbarkeit und Funktionalität von Automobilkomponenten. Durch die sorgfältige Auswahl der geeigneten Oberflächentechnik können Automobilingenieure optimale Leistung, Haltbarkeit und Kundenzufriedenheit sicherstellen.

Denken Sie daran, dass Oberflächenbehandlung und Qualitätskontrolle eng miteinander verbunden sind, wenn es um OEM-Aluminiumteile in der Automobilindustrie geht. Indem Automobilingenieure über die neuesten Fortschritte bei der Oberflächenbehandlung informiert bleiben und Spitzentechnologien, wie RFA, integrieren, können sie Innovationen vorantreiben, die Produktleistung steigern und in dieser dynamischen Branche erfolgreich sein.

Ähnliche Themen

Handanalysator für die Röntgenfluoreszenzanalyse (RFA) für chromatfreie Konversionsschichten

Video: DURA Automotive verwendet den Vanta RFA-Handanalysator für die Qualitätskontrolle

Durch dick und dünn: RFA für die Messung der Beschichtungsdicke