Achieve More with Intuitive Measurement Tools3DAssist™ software’s powerful and intuitive measurement tools unlock a new level of insight, revealing hidden defects inside your pipes and assets. |

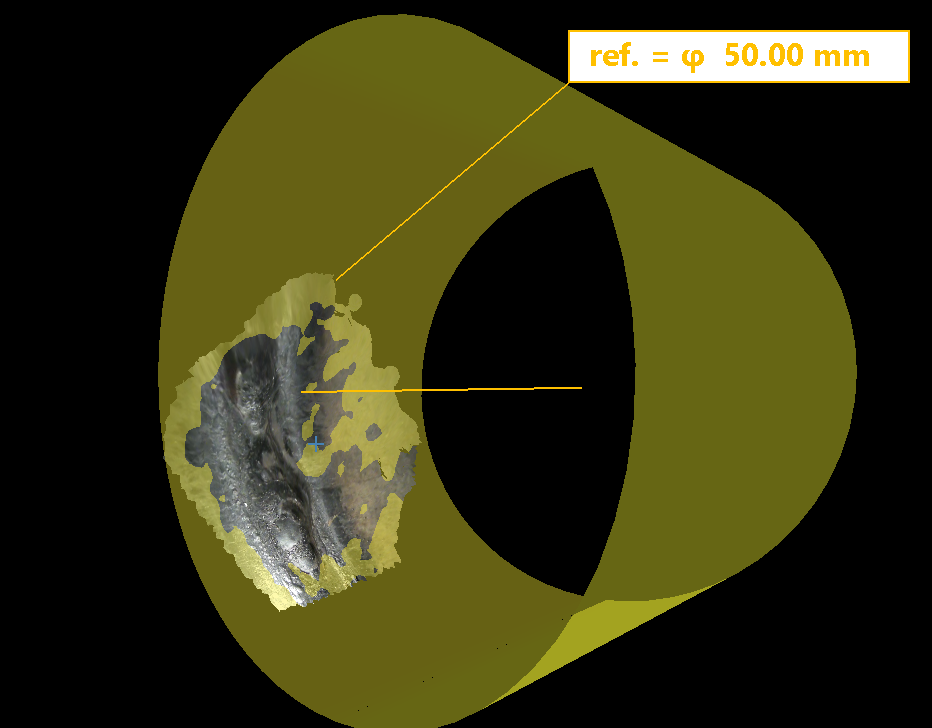

Measurement Mode to Solve Piping Inspection ChallengesIn piping inspections, accurately assessing bulges and wall thinning is crucial. Point to Curve measurement mode enables precise depth and height measurements using the pipe's surface contour as a reference. With this innovative method, you can evaluate defects more precisely than with conventional methods. | Left: 3D view of a bump sample. Right: The same sample in Point to Curve measurement mode with Color Gradient analysis. You can easily understand the higher and deeper areas using Color Gradient and place the measurement point using Point to Curve mode.

|

|---|

Comprehensive Analysis Tools to Elevate Your Reports3DAssist software provides a variety of analysis tools designed to significantly enhance the quality of your reports. These include:

| Incorporating these quantitative insights into your inspection reports will elevate them to a higher level of clarity and depth.

|

Unlike complicated analysis tools, 3DAssist software is optimized to provide an intuitive and consistent user experience. A simple and clear workflow reduces the analysis time, so you can reach accurate conclusions faster than ever. Left: 3D view of an airfoil with Distance and Depth measurement. Right: The curved shape of the whole reference cylinder.

|