Bone loss can occur due to a variety of causes. This includes bone fractures caused by muscle and bone deterioration from aging or lifestyle changes, bone tumors, osteomyelitis, and loosening of artificial joints.

To replace bone loss, an autologous bone graft is used, where the patient's own bone is transplanted from a different part of the body. This technique has the advantage of using the patient's own living tissue, which has no immune response and has excellent bone formation capabilities. However, the surgical procedure to harvest the bone that can be transplanted is taxing on the patient's body, and the amount of bone harvested may not be sufficient.

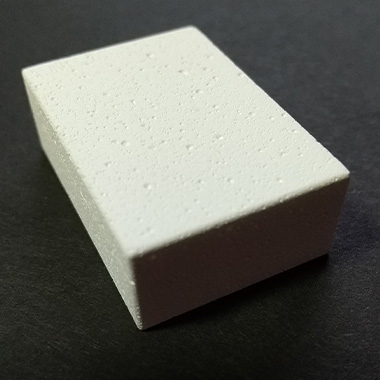

Artificial bone grafts are an effective solution to these problems. They can be used to fill in bone defects and gaps to stabilize the tissue. The porous calcium phosphate-based ceramics are available in block, granule, and paste forms. These forms are selected according to the shape and size of the bone defect to suit the workability.

The pores in the filler material can be as large as 100–200 µm in diameter to enable the growth of osteoblasts or as small as a few µm in diameter to help supply air and nutrients to the inside of the bone. In some cases, block-shaped filler materials need to be strong to prevent the material breaking during surgery or recovery. If the material breaks, it will affect the healing process.

As a result, controlling the pore size and its ratio is important because the dispersion of pore size and strength greatly influence the performance of the bone replacement material.

The Challenges of Observing Pore Size

Until now, observation of pores has been performed using scanning electron microscopy (SEM) and other methods on small pieces of resin-embedded filler material. However, the sample preparation involved in these methods, such as the sample fragmentation, resin embedding, and sputtering used in SEM, added two to three days to the inspection time. Today there is a faster method―3D laser scanning microscopy.

Measurement Solution for Evaluating Pore Size of Artificial Bone Replacement Material

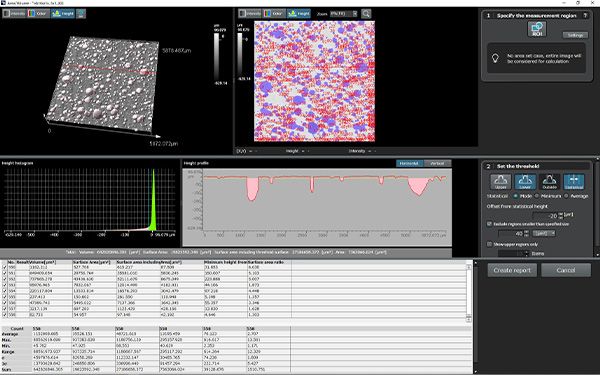

Inspectors can quickly evaluate the pore size of artificial bone replacement material using a 3D laser scanning microscope such as the LEXT™ OLS5100 system. This microscope combines powerful measurement capabilities with a simple workflow so users of all skill levels can measure the area ratio, pore diameter, and pore depth with ease.

Solution benefits:

- Uses a 405 nm laser, which enables you to immediately begin a nondestructive observation by simply placing the sample on the stage. No sample preparation is required, significantly shortening the inspection time.

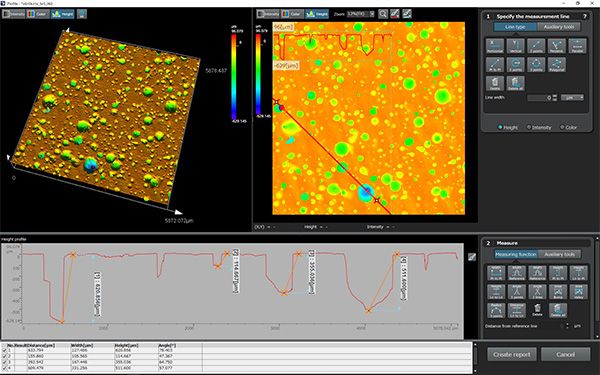

- Can acquire height data in a plane, enabling a wider range of measurements and observations. This includes pore diameter and area ratio by particle analysis, pore depth measurement by profiles, and 3D display. Tolerance judgment can also be used to make a pass/fail judgment of individual measurement results against a set standard.

- Can stitch 3D data together in a planar orientation, enabling the acquisition of highly accurate data over a wide area.

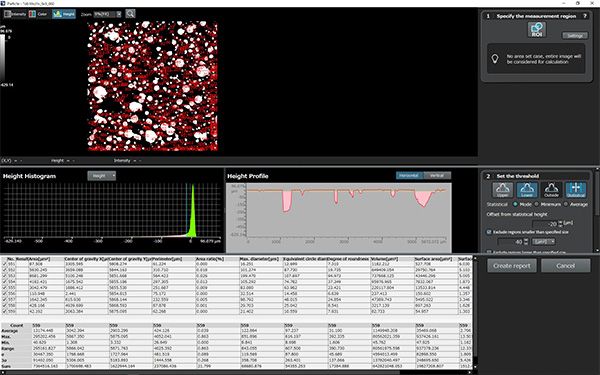

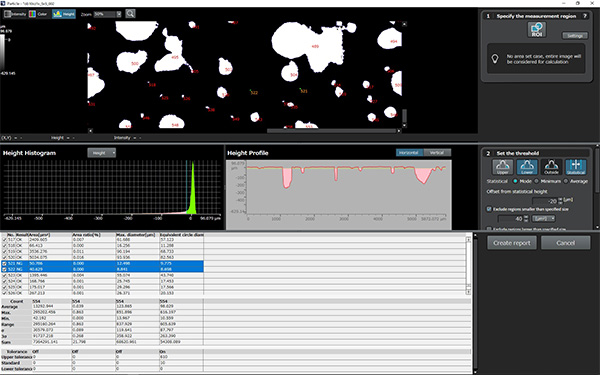

Particle analysis (area ratio of pores, maximum diameter, Feret diameter, and equivalent circular diameter).

Images captured using a 10X objective lens and stitched into a 5 × 5 image (5 mm square).

Particle analysis tolerance determination.

For example, when focusing on the equivalent diameter and checking for pores larger than a certain size, a pass/fail judgment can be displayed for all measured particles. This is done by setting a reference value and upper and lower limits (±), which can be transferred to Microsoft Excel.

Profile measurement (depth of hole).

Area/volume measurement (pore area/volume).