1. Background

A vehicle’s overall quality is equal to the sum of its parts, and it is imperative for manufacturers to maintain rigid standards of excellence for every component. Manufacturers must also take into account requirements such as emission reduction, fuel efficiency, long-term durability, and regulatory standards. The increasing complexity of auto parts and components also requires manufacturers to place a strong emphasis on material characteristics, fitting tolerances, and technical cleanliness, which all play a strong role in the long-term durability, durability, and life-expectancy of the final product. Particle contaminants can directly affect a part’s reliability, especially when the part is assembled using components from multiple suppliers. As systems and components shrink, even the smallest particles can cause catastrophic failure, making it essential to assess the technical cleanliness and integrity of components and liquids.

2. Application

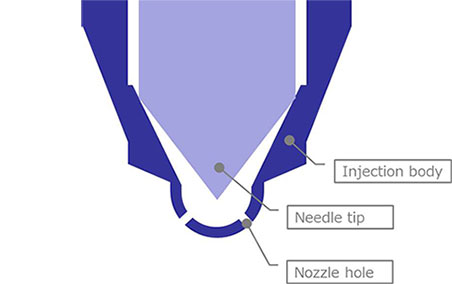

A diesel injector is a vital, ultra-precision part used in diesel engines. The injector has a small nozzle (50 to 250 μm) that injects diesel fuel into the engine’s combustion chamber at high pressure (Figure 1). If the nozzle is clogged with contaminants, the engine’s efficiency may decrease and the engine or injector may be damaged. Checking the cleanliness of diesel injectors is one of the most important steps in the injector manufacturing process, and helps prevent metal chips and other contaminants from damaging the engine.

Figure 1. A diagram of a diesel injector.

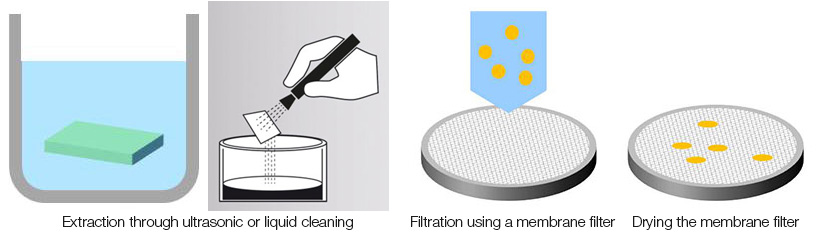

Counting the number of contaminant particles is an important method for evaluating the cleanliness of injectors. The contaminant particles are first removed using a liquid shower or an ultrasonic bath. The washing rinse is then filtered through a membrane to collect the extracted particles, and the filter membrane is dried for the further analysis. Once the sample is fully prepared, the particles trapped on the filter surface are evaluated using a microscope (Figure 2). Once the size and number of particles are quantified, the data must be analyzed and evaluated according to industry standards to determine the injector’s technical cleanliness.

Figure 2. The process of inspecting the cleanliness of a diesel injector.

3. The Olympus solution

Olympus' CIX100 Technical Cleanliness Inspection System is a dedicated, turnkey solution for manufactures who need to evaluate the cleanliness of essential components, ensure their compliance with company and industry standards, and document the results for their customers. The system automatically scans the entire filter membrane surface using a combination of advanced microscopopy, a motorized XY stage, digital camera, and software. Both reflecting and non-reflecting particles are counted and sorted into size classes in accordance with defined standards. The CIX100 system supports major international standards, including: ISO 16232-10 (A) (N) (V), VDA 19.1 (A) (N) (V), ISO 4406, ISO 4407, ISO 12345, NAS 1638, NF E48-651, NF E48-655 and SAE AS4059.

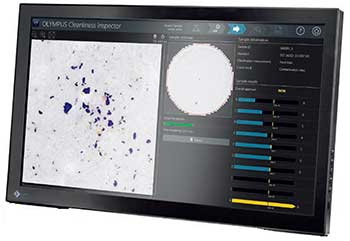

All relevant data, including live and oveview images, are displayed live on a single screen during the inspection (Figure 3), where a statistical control chart visually illustrates the level of particle class compliance for improved reliability. Thumbnail images of each contaminant are linked with dimensional measurements for easy data review, and results are reported using a customizable Microsoft Word template. Long-term data storage provides access to results and decisions for future review.

Figure 3. Image processing discriminates between contaminant types captured by the Technical Cleanliness Inspection System. |

Figure 4. A cleanliness analysis report. |