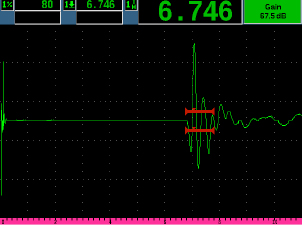

This application note explores how to measure the depth of steel and fiber ply cords or belting in all types of rubber tires, as well as the total wall thickness in some cases. Quality Control in Rubber Tire ManufacturingFor quality control purposes, manufacturers of rubber tires need to know the position of the steel or fiber ply cords that are embedded in the walls of automotive, truck, and off-road vehicle tires. This is particularly important in the case of the large, expensive tires used for heavy trucks and construction equipment, where improper cord positioning can lead to costly failures. In some cases, manufacturers also want to measure total wall thickness. These measurements require special consideration because rubber is very attenuating to high-frequency sound waves and because of the complex pattern of echoes that are generated by the internal structure of most tires. Equipment for Rubber Tire Thickness MeasurementThere are two common approaches to rubber tire measurement, depending on the thickness of the tires to be measured. We recommend the following instruments for specific applications: 1. Ultrasonic Thickness Gauges for Automotive and Light Truck TiresThe first method uses an ultrasonic thickness gauge, such as a 39DL PLUS™ or 45MG gauge with Single Element software, paired with an M1036 (2.25 MHz) transducer. These gauges are used mostly for automotive and light truck tires, and—along with a low-frequency transducer—are generally used to measure the depth of ply cords only. The measurement range is approximately 3 mm (0.125 in.) to 25 mm (1 in.), with a calibrated accuracy of ± 0.25 mm (0.01 in.) or better. The waveform display, which is standard on the 39DL PLUS gauge and optional on the 45MG gauge, is useful for verifying detection of the first ply cord echo that represents the minimum rubber thickness. 2. Ultrasonic Flaw Detectors for Larger TiresThe second method uses an ultrasonic thickness gauge, such as an EPOCH™ series flaw detector with a square wave pulser. Either the EPOCH 6LT or EPOCH 650 instrument used with selected low-frequency transducers would work. These square wave flaw detectors with selectable bandpass filtering offer much greater penetration than a thickness gauge and are recommended for larger tires, such as those for trucks and off-road vehicles. Rubber thicknesses of 200 mm (8 in.) or more can usually be measured with 500 kHz transducers, sometimes in pairs in pitch-catch mode. Typical measurement accuracy ranges from ± 0.25 mm (0.01 in.) or better on passenger car tires to ± 1 mm (0.04 in.) on very large truck and off-road vehicle tires. Procedure to Measure Rubber Tire ThicknessSound attenuation and internal structure vary widely between various types of tires, so it is important to evaluate each application individually. The measurement of rubber always requires low-frequency transducers of 2.25 MHz or lower. In some cases, it is advantageous to use a transducer with an epoxy wear surface to improve sound coupling between the transducer and the rubber. Commonly recommended transducers for tire testing are the M1036 (2.25 MHz, 12.5 mm [0.5 in.] diameter, high penetration) and the V601-RB (500 kHz, 25 mm [1 in.] diameter). In applications involving very thick tires (greater than 4 in. or 100 mm of rubber), pairs of V601-RB transducers have been successfully used in pitch-catch mode with a flaw detector. Separating the transmitter and receiver functions allows the use of very high receiver gain without the potential noise problems associated with amplifying the excitation pulse recovery. Gel couplant is normally recommended for all rubber tire applications. To help ensure good wetting, the couplant must be worked into the surface. As with any ultrasonic thickness measurement, it is necessary to calibrate the sound velocity of the rubber in question using a sample of known thickness. The velocity of rubber changes rapidly with temperature, so for best accuracy, the sound velocity must be measured at a temperature that closely corresponds to actual measurement conditions. Successful ultrasonic measurement of total tire thickness—as opposed to the depth of the ply cords—depends on the structure of the ply cords. In some types of tires where there are many layers of ply cords and/or the ply cords are very close together, not enough sound energy will reach the inside wall to permit measurement of the total thickness. In other tires where there is more separation between the individual ply cords, some sound energy will get through to the inside wall and measurement of total thickness will be possible. This must be evaluated on a case-by-case basis. In cases where an inside wall echo is visible, the instrument can be switched to a second stored setup that can be used to make the measurement. Figure 1 shows the echo from steel ply cords, measured from the outside tread, in an automotive tire whose tread is approximately 12.5 mm (0.5 in.) thick. It is measured here with the 39DL PLUS gauge and an M1036 transducer (2.25 MHz). In this case, the echo is measured to the first positive lobe.

Figure 1 Figure 2 shows the total wall thickness measurement of a large construction vehicle tire with a thickness of approximately 171.5 mm (6.75 in.), using an EPOCH 650 flaw detector in through-transmission mode with two 500 kHz V601-RB transducers. The measurement gate has been positioned to capture the rubber thickness, which is represented by the peak near the right side of the display.

Figure 2 |

Measuring the Thickness of Rubber Tires

The 39DL PLUS™ gauge is field-proven and reliable for virtually every ultrasonic thickness inspection. It works as a precision or corrosion thickness gauge to meet the challenges of demanding applications across industries, including maintenance, manufacturing, and energy production. With world-class ultrasonic capability, fast scanning speeds, and fully integrated wireless connectivity, this handheld gauge delivers results you can trust in a seamless workflow.

The 72DL PLUS™ advanced ultrasonic thickness gauge delivers precision thickness measurements at high speed in a portable, easy-to-use device. Compatible with single element transducers up to 125 MHz, this innovative instrument is ideally suited to measure the thickness of ultra-thin materials, including multilayer paint, coatings, and plastic. It can simultaneously display the thickness of up to 6 layers.