This application note summarizes important information on normal incidence shear wave transducers, such as our V150-V157 and V220-V222 series. These transducers are commonly used with ultrasonic thickness gauges, flaw detectors, or pulser/receivers to measure shear wave velocity in test materials, often in connection with the calculation of elastic modulus as described in our application note on Elastic Modulus Measurement.

How Normal Incidence Shear Wave Transducers Work

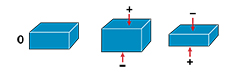

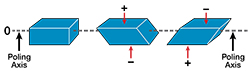

Normal incidence shear wave transducers are single element contact transducers that introduce shear waves directly into the test piece without the use of refractive mode conversion. By definition, these waves propagate perpendicular to the test surface while particle motion is parallel to the surface. The transducers use piezoelectric elements cut perpendicular to the electrical poling direction so that, when pulsed, they vibrate in shear (transverse) mode rather than longitudinal (compressional) mode when an excitation voltage is applied, as seen in the concept drawing below.

Longitudinal wave element |

Shear wave element |

5 Key Considerations When Using Shear Wave Transducers

Because of their specialized nature, shear wave transducers require attention to the factors noted below for good response.

1. Excitation pulse limit

Always drive shear wave transducers with the lowest excitation voltage possible in a given test, preferably 100 volts. When too much power is delivered to the transducer over time, the element can actually be re-poled to a longitudinal mode element. This effect can occur with long-term use of the 300–400 V pulsing available in most ultrasonic flaw detectors. Higher frequency elements (5 MHz and up) are most susceptible to this re-poling because they are thinner. There is no way to reverse this effect. When damaged this way, the re-poled transducer essentially becomes a longitudinal wave transducer.

2. Coupling

A high viscosity shear wave couplant, such as SWC-2 (Q7700010), must be used to couple a normal incidence shear wave into the test piece. Standard ultrasonic couplants will not work because they are liquids or gels. A basic property of a liquid is that it does not support a shear stress. Thus, low and medium viscosity liquids, such as conventional ultrasonic couplants, will not transmit shear waves.

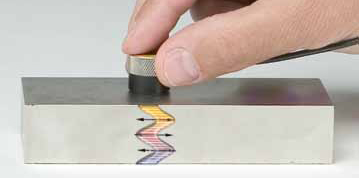

For best results, use a very thin layer of the SWC-2 high viscosity couplant with firm coupling pressure. The suggested procedure is to put a very small amount of couplant on the transducer and spread it into a thin layer with a razor blade or straight edge, then couple onto the test piece and further wring out the couplant by rotating the transducer. You will typically see the echo amplitude increase as the couplant layer becomes progressively thinner.

3. Polarization direction

The direction of polarization of the shear wave (the axis of particle movement) in our shear wave transducers is nominally in line with the right-angle connector in standard RM and RB style cases. Shear wave transducers with SB or SM connectors have a line engraved on the case marking the polarization axis. In anisotropic materials, it is common that pulse transit time and amplitude will vary as the transducer is rotated on the surface of the test piece, which changes the orientation of particle movement with respect to directionally varying the mechanical properties of the material.

4. Material attenuation

Shear wave propagation is typically good in common engineering metals and ceramics unless a coarse grain structure is present. However, shear wave attenuation is usually extremely high in flexible materials such as rubber and soft plastics. Thus, there will typically be no usable shear wave echo, even with proper couplant. Hard plastics, such as acrylics, as well as structural composites usually do transmit usable shear waves at low ultrasonic test frequencies, but care should be taken with transducer selection and instrument setup.

5. Longitudinal wave artifacts

All normal incidence shear wave elements generate some underlying longitudinal wave energy as well. Typically, this longitudinal component is at least 30 dB lower than the shear signal. However, in materials with very high shear attenuation and lower L-wave attenuation (such as flexible plastics) or in situations where non-viscous couplants are used, the shear component may be highly attenuated while some L-wave energy remains and is seen as the primary waveform in the display. This phenomenon can also occur when shear wave transducers have been damaged by excessively high excitation voltages, as noted in the excitation pulse limit section above.

For further information on normal incidence shear wave transducers, please contact us.