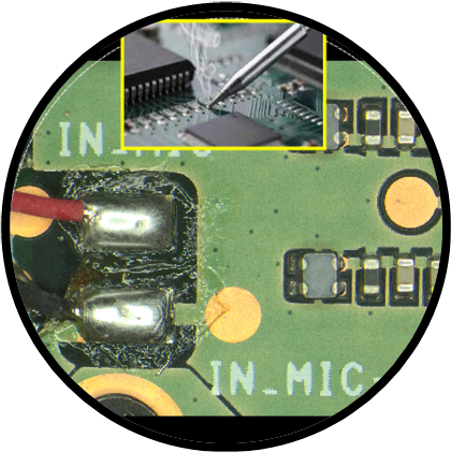

Augmented reality can simplify complicated microscope-based manufacturing processes by overlaying text, images, videos, and measurements into the view seen from the eyepieces. This technology enables users to follow directions, point out potential defects on the sample, and watch videos—all without having to remove their eyes from the oculars. To bring the power of augmented reality to our microscopes, we developed the AR1 module. The AR1 module turns our SZX stereo microscopes into powerful augmented reality tools for microscope-based manufacturing tasks, such as:

This smart augmented reality system speeds up manufacturing tasks in three main ways: |

1. More Efficient Assembly ProcessStandard operating procedures (SOPs) can be displayed in the microscope’s field of view. With the directions projected onto the sample, workers don’t need to take their eyes away from the microscope to check a digital or printed SOP. This enables the worker to stay on task, perform work more efficiently and comfortably, and reduce the chance of memorization errors. Various items can be projected into the worker’s field of view, such as:

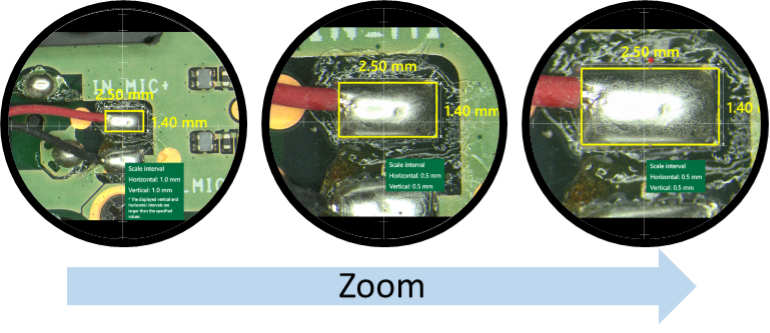

Note that gauges and reticles automatically adjust to the zoom magnification to enable accurate dimensions. |

The zoom magnification sensor tracks the magnification in the software to help ensure correct measurements

For ease of use, the SOPs are created in a slide presentation format. Simply build SOPs with multiple steps as numbered slides, and workers can load these SOP slide decks for different assemblies and tasks. It’s also easy to access and navigate through the SOPs thanks to smart features. The barcode scanner lets you scan QR codes to quickly open specific SOPs. You can easily move forward and backward through the SOP using buttons on the zoom magnification sensor or using a third-party footswitch for hands-free navigation.

2. Improves Employee Training

Augmented reality microscopes can also increase training effectiveness and minimize costs. In fact, one of our customers found that using the AR1 module on their stereo microscope reduced their training time from six weeks to four days.

Here’s how it works:

Using the AR1 module, trainees don’t have to alternate looking through the eyepieces and checking a reference document. The trainer can point out areas of interest using the software functions for annotations, such as the pen, shapes, text, images, videos, reticles, and gauges. These annotations appear in the field of view so that the trainee can easily follow along.

Training workers to perform electronics assembly tasks is a straightforward process using an augmented reality microscope

In addition, the AR1 module reduces costs through remote training. Assemblers can easily share the field of view using third-party collaboration software, such as Microsoft Teams, with offsite managers for remote guidance. This cuts down on travel costs as managers can perform the training from anywhere. Trainings can also be easily recorded via Microsoft Teams to save as future trainings and refreshers. These recorded training videos can be projected into the field of view to save time.

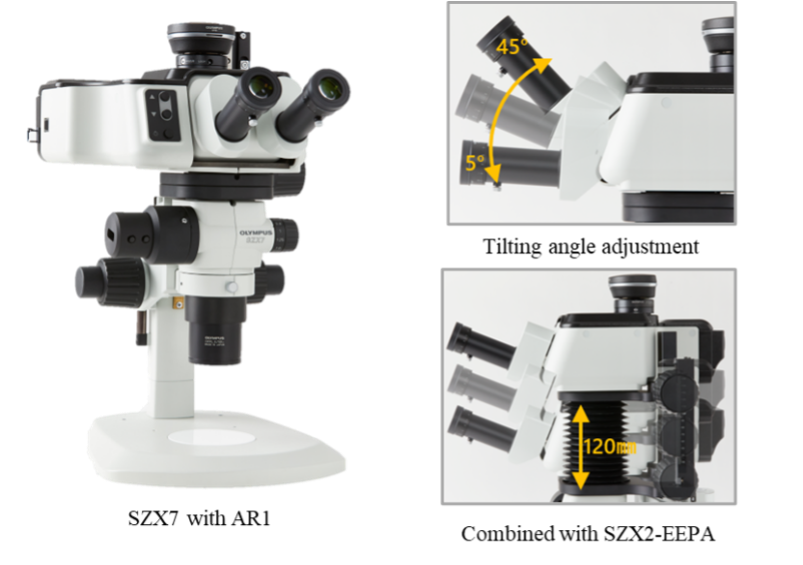

3. Keeps Workers Comfortable

To improve efficiency and safety, our SZX stereo microscopes used in the augmented reality system promote proper ergonomics. The tilting trinocular head and eyepoint adjuster enable assemblers to adjust the microscope to a comfortable, natural posture. Further, the AR1 module reduces head and neck movement by projecting instructions directly on the field of view.

The SZX-AR1 augmented reality microscope system features ergonomic components, such as a tilting trinocular head

Learn More about Augmented Reality Microscopes for Manufacturing Tasks

The AR1 module improves device inspections and assemblies using stereo microscopes by maximizing efficiency, minimizing training costs, and supporting proper ergonomics. Another benefit is the seamless integration process into both new and existing SZX stereo microscopes. For existing SZX microscopes, minimal components need to be added:

- The AR1 tilting trinocular head

- Camera: DP23, DP27, or DP28 digital microscope camera

- Monitor

- PC (if current system is not already equipped with one)

To learn more about how automated reality can improve your manufacturing process, check out the quick video below:

Related Content

Video: Introducing Augmented Reality Microscopes for Manufacturing

Brochure: SZX-AR1 Augmented Reality Imaging System

Get In Touch