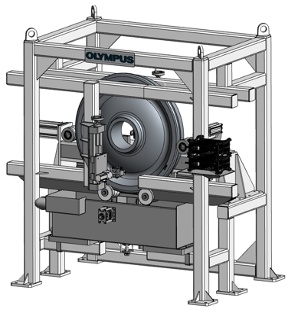

The bottom line for manufacturing facilities often means increasing production line productivity to remain competitive. Quality control (QC) is an area of production that can be a bottleneck. Train wheel manufacturers seeking faster and more reliable QC can benefit from our phased array ultrasonic testing (PAUT) based Train Wheel Inspection System (WIS).

| It’s a cost-effective solution for manufacturers looking to increase their inspection efficiency, offering a high return on investment (ROI) thanks to three key benefits: 1. Easy IntegrationContrary to more cumbersome and inflexible in-line inspection systems, the WIS is designed to adapt to fit the physical specifications of the train wheel production line.

|

The WIS is scalable to optimize productivity and easily configured for top loading if required

Electronics are all onboard; the data acquisition devices (four FOCUS PX units, one per probe) are contained on the system itself

- Input/output OPC enables communication with the production line

2. Simple Operation and Fast Inspection

The WIS provides train wheel manufacturers with a reliable, easy-to-operate phased array inspection solution supported by application-dedicated software:

Fast (less than 1 minute) inspection of all parts required by international manufacturing standards (volume of the rim from the tread and side, as well as both hub faces)

RailView software provides a clear image of the wheel with flaws

Go-no-go configuration possible for operators with less experience

Automatic adjustment by the software to a change in wheel size (diameter, profile, and weight)

To learn more about the powerful data acquisition device that drives the phased array inspection, check out our FOCUS PX.

3. Reliability and Durability—Built for the Long Haul

When developing Olympus’ train wheel inspection system (WIS), our engineers realized that many in-line systems on the market are overly complex and poorly designed for the rigors of the production floor. Here are a few factors behind the WIS’s longevity:

Adjustment mechanisms and rollers are positioned so they stay dry, eliminating unnecessary wear and corrosion and extending the life of the system

Containing the electronics on the system reduces the probe cabling length

Retaining arms prevent shock to the rollers, minimizing misalignment and adjustments

Manufactured using high-quality, durable components

- Dependable global support: as manufacturer, provider, and installer of the WIS, we perform on-site testing to ensure the system’s performance meets our guarantee

We also support the WIS through the life of the system. Olympus is dedicated to our customers’ satisfaction, providing high-quality service around the globe.

Go to www.olympus-ims.com or Contact Us for more information.

Related Content

Introduction to the Olympus Automated Train Wheel Inspection System

Automated Train Wheel Inspection System

Inspecting Train Wheels Using Phased Array

Get In Touch

.jpg?rev=E9A9)