In a previous post, we mentioned how critical it is for pharmaceutical manufacturers to visually inspect newly fabricated welds in processing pipes. Regional standards, such as ASME BPE 2016, govern the construction and certification of bioprocessing and pharmaceutical equipment. These standards provide strict guidelines for the initial visual inspection of new welds, including an examination log of the results for each weld. Remote visual inspection (RVI) tools such as borescopes or videoscopes are typically used for this assessment.

Pharmaceutical plants also need to enact regular cleaning and maintenance protocols that align with good manufacturing practices (GMP). An important part of plant maintenance includes periodic visual inspections of in-service welds, elbows, and joints in process pipes. These are typical problem spots for residue buildup and production-line contamination. Again, borescopes or videoscopes are the tools of choice to inspect these difficult-to-access targets.

In-service weld inspection protocols include keeping careful records to monitor equipment hygiene and integrity. The same goes for other pharmaceutical production equipment—tanks, vessels, mixers, etc. All processing equipment needs to be strictly examined, validated, and documented on a regular basis.

Streamline Your BPE Weld Inspection Log Process

Fortunately, there are software tools to help ease the rigorous inspection documentation demands placed on pharmaceutical plants. Traditionally, before beginning a borescope inspection, you would refer to isometric drawings to plan your inspection based on the equipment design and target locations.

Since you may have numerous locations to inspect—hundreds, even thousands, of welds, in some cases—managing the RVI image archive and generating inspection reports can be complex tasks.

The Standard Visual Inspection Workflow: Tedious and Time-Consuming

When recording inspection images with a standard borescope, you can usually add text directly on the image. When using ASME BPE 2016’s Form WEL-1 Weld and Examination/Inspection Log, the inspector designates a location and weld number for each weld they inspect. So, embedding the location and weld number on the image enables the inspector to associate it with a specific weld in the weld inspection log.

Pharmaceutical plants need to record these weld inspection images as part of evidential data and to produce reports. If you want to recall and review the images later, you may waste a lot of time scrolling through numerous image files and opening each one to find what you need. And preparing your report is also tedious since you have to manually copy and paste each image into the document.

Read on to learn how our IPLEX videoscopes and InHelp™ Viewer software can help you better manage image and video files during your equipment inspections and make your report generation more efficient.

Simple Tricks to Make Image Management Easier During Inspection

Using the IPLEX image folder management function, you can create image folders for each location and weld number before you start the inspection. When you capture a still image, the file is automatically named, including the folder name plus a 5-digit sequence number, i.e., “location_weld#_00001.jpg”.

Video file names are generated using the same logic. Because the file name includes the location and weld number, it's easy to identify the inspection object without opening it. This improved visibility makes managing your files and preparing your report much smoother.

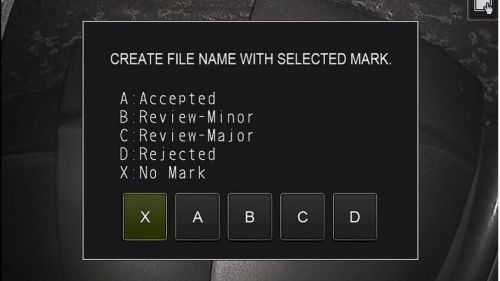

As you record your images, you can use the IPLEX videoscope’s File Mark function to attribute an accept, reject, or review diagnosis to the weld. You can preset up to 5 severity levels; for example:

- A for Accepted

- B for Review Minor

- C for Review Major

- D for Rejected

- X for New or Normal

This diagnosis data is saved with the file and displayed with the image in the InHelp Viewer gallery for easy post-inspection review. InHelp Viewer is our IPLEX videoscopes’ complimentary companion software for PCs.

When you move to inspect a new weld, you can easily switch to the next location/weld number folder using the joystick or the arrows on the touch screen.

Boost Your Efficiency with Advanced Automatic Report Generation

Report generation is fast and efficient with InHelp Viewer; simply click to select images to include them in the report, eliminating time-consuming copying and pasting. While reviewing your images, you can also update diagnostic results and add and edit comments. Once the relevant images are selected and you’re satisfied with the diagnostic data, choose from among your saved templates to generate a complete report.

Pro Tip #1: When you use the IPLEX videoscope's File Mark function, it can also add the diagnosis attribution (A, B, C, or D) to the end of the image file name. This enables you to know at a glance the severity of that weld. When reviewing the images in the gallery in InHelp Viewer, you can choose to sort and display them according to their A, B, C, and D attributions, respectively. This can help expedite your inspection review and image selection for your report.

Pro Tip #2: Give your reporting process an efficiency boost. When you periodically inspect the same production equipment, InHelp Viewer software can be configured to enable you to automatically generate reports with images and linked video clips. If you are interested in InHelp Viewer software’s automatic report generation, contact your local Olympus representative for more details.

I hope you found these tips for documenting your processing-equipment inspections helpful. Note that InHelp Viewer is available for free on our Software Downloads webpage (under IPLEX).

Related Content

3 Ways to Maintain Pristine Pipe Welds in Pharmaceutical Plants Using RVI

Keeping an Eye on Contamination in the Pharmaceutical Processing Line

Olympus Borescopes and Visual Inspection Equipment

Medical Device Industry Medical Device and Component Inspection

Get In Touch