Industries

Oil & Gas

|

Olympus Solutions for Oil & Gas

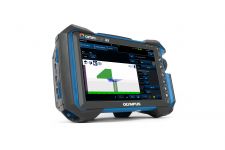

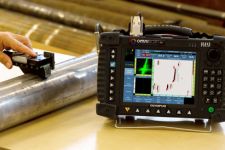

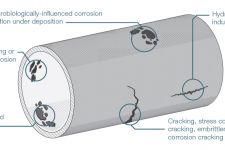

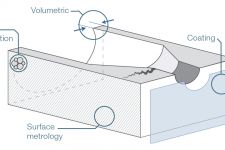

In the oil & gas industry, safety is the highest priority, and unplanned downtime is costly. A robust nondestructive testing program is important to help maintain the safety of people and the environment and keep pipelines operating efficiently.

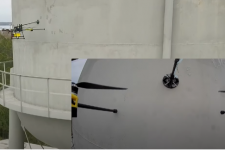

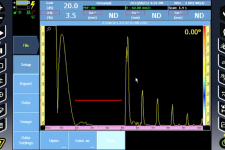

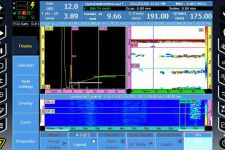

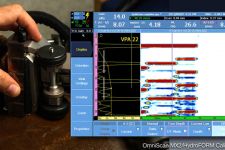

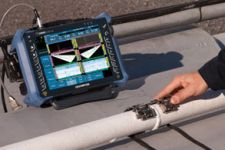

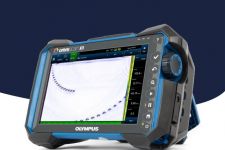

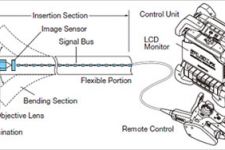

Inspectors use X-ray fluorescence analyzers to verify that pipelines are made from the proper alloy and ultrasonic and phased array flaw detectors to check pipelines and welds for flaws and corrosion. Worker safety is paramount when it comes to inspections in challenging environments, like offshore and at height, so options like harnesses and one-handed operation make all the difference.

Corrosion Inspection Solutions Corrosion Inspection Solutions |  Weld Inspection Solutions Weld Inspection Solutions |  Measurement Solutions Measurement Solutions |  Vanta for PMI Vanta for PMI |  Tube Inspection Solutions Tube Inspection Solutions |  Bar Inspection Solutions Bar Inspection Solutions |

More Resources

Sorry, this page is not available in your country

Let us know what you're looking for by filling out the form below.