OLYMPUS CIX90

Productos discontinuados

Reliable

This product has been discontinued, check out our current cleanliness inspection system >>

Easy Setup for True Turnkey Functionality

Each component of the OLYMPUS CIX90 system is optimized for accuracy, reproducibility, repeatability, and seamless integration for reliable data in a high-throughput system. Leading-edge optics and imaging sensor are combined with an intuitive software workflow and integrated calibration and maintenance tools to help ensure that you’re using the correct settings.

1. Camera Cover |

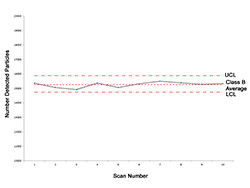

Reproducibility and Repeatability

High reproducibility: The diagram illustrates the variance of results for a validation sample run through the system ten times, illustrating the system’s precision. | The OLYMPUS CIX90 system is easy to use, so even inexperienced inspectors can acquire accurate and reliable data. Preconfigured, optimized hardware and dedicated system solutions help ensure that your settings are correct for accurate and repeatable inspection results. |

Excellent Optical Quality

| UIS2 objectives help ensure the best optical performance for excellent measurement and analysis accuracy. A dedicated light source maintains a consistent color temperature optimized for cleanliness inspection. |

Accurate Data

The integrated calibration slide helps maintain regular system verification. | Reproducibility has been optimized by eliminating moving parts from the illumination light path, maximizing automatic functionality, and creating intuitive workflows that limit potential operator errors. The integrated calibration slide helps maintain regular system verification. |

Fast Speed

| A innovative illuminator helps differentiate between reflecting and non-reflecting particles in a single scan, reducing inspection time by a factor of 2. |

Intuitive

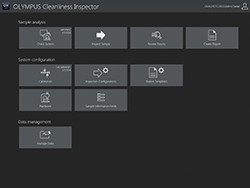

Software Guidance at Every Step

The new user interface not only makes cleanliness inspection repeatable and reproducible but also easy for experts and non-experts alike. | The OLYMPUS CIX90 system redefined user operation to make cleanliness inspection easy. The system reduces the need for complicated adjustments, and the workflow is based on just three steps: Inspect Sample, Review Results, and Create Report. The system provides extensive user guidance through each step in the inspection process with respect, helps users make inspections according to the selected international standard, and maximizes the use of automated functions. |

New User Interface

The intuitive workflow is based on just three steps so cleanliness inspection is not only repeatable and reproducible but also easy for operators to carry out. | OLYMPUS CIX90 redefined the user operation and make cleanliness inspection easy for everyone even by non-experts. Every kind of user produce inspection data they can rely on. The system reduces complicated adjustment by extensive. The intuitive workflow is based on just three steps: Inspect sample, Review results and Create Report. The system reduces complicated adjustment by extensive user guidance leading through all process steps in respect of international standards and by a maximum use of automated functions. |

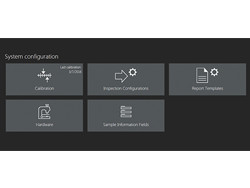

System Configurations

| The OLYMPUS CIX90 system is already configured and calibrated when it is delivered but can be easily modified and customized to your applications and requirements. |

Data Management

The data management section is where users can access sample data and reports.

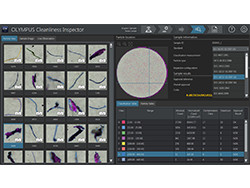

Sample Analysis

The sample analysis section contains all of the functions associated with analyzing a sample and checking the results including sample inspection, detection, and classification.

During the inspection process, all of the relevant data are displayed on a single screen, including live overview images and class results.

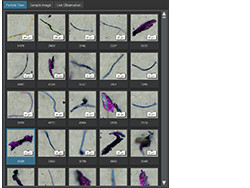

Result Review

Thumbnails of the largest particles are displayed | Thumbnails of all detected contaminants and dimensional measurements in every classification bin are linked together. It is easy to quickly review, revise, and recalculate all of the particles detected in the sample before documenting the results. |

One-Click Reporting

Professional analytical reports are produced with one-click reporting | Intuitive report creation makes it simple to produce reports that comply with international standards. |

Informative

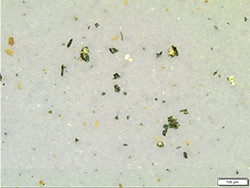

Efficient Data Evaluation

Thumbnail images of all detected contaminants are linked with their dimensional measurements, making it simple to review, revise, and recalculate particle data before documenting the results | The OLYMPUS CIX90 system makes reviewing and documenting your samples quick and easy. Thumbnail images of every contaminant detected by the system are linked together with dimensional measurements, making it easy to review the data. Retrieving a particular contaminant’s information is simple. Through the review process, all results are updated and displayed automatically in all views and size classification bins. |

Particle and Sample View

| Thumbnails of detected particles are displayed in the particle view in order from largest particle to smallest. The sample view displays the selected image in full view, showing the complete particle even when the image is stitched together. |

Particle Location

| When selecting a dedicated thumbnail, its location is automatically shown in the overall image. With just one click, particles can be deleted or reclassified into another particle family. |

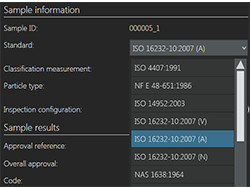

Standard Configuration

Screen showing the selected inspection configuration | The current inspection configurations are highlighted in the interface so you clearly know what standard is being used. All other defined and available configurations are listed and can be selected by clicking your mouse. The data are automatically recalculated when you change configurations. |

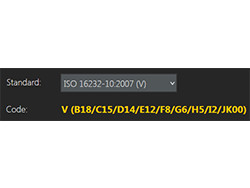

Overall Result

The resulting component cleanliness code is depending on the standard and is composed of the size classes and the contamination levels of particles found. | The overall classification results based on the selected standard are calculated and displayed. |

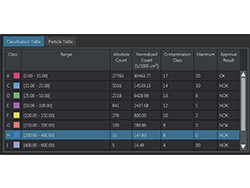

Classification and Particle Information

| Classification and particle tables show the results according to the selected standard and particle data respectively. If necessary, the results can be recalculated with a different standard. Thumbnail images and data are updated automatically. |

Link Data to Particle

| Thumbnail images of all detected contaminants are linked with their dimensional measurements, making reviewing, revising, and recalculating particle data before documenting the results simple. |

Reclassification

Different Cleanliness Codes | The system supports one-click reclassification of all supported standards. Select the standard and the cleanliness code is displayed. |

Quick and Easy: Review, Revise, and Recalculate

Operators can easily revise their inspection data. Powerful software tools including delete, split, and merge make revising the data simple.

Particles can be edited during the revision process.(1. Delete, 2.Split, 3.Merge)

Compliant

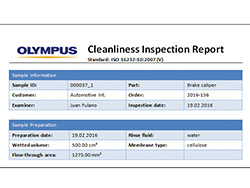

One-Click Reporting

Reports that comply with international standards. | Users have the choice of creating analytical reports that comply with the standard used during analysis or create their own custom templates in MS Word with a single mouse click. Templates and reports can be easily adapted to meet company regulations. |

Efficient Report Creation

Predefined templates for easy reporting. | Creating a report can take longer than capturing the image and taking the measurements. The OLYMPUS CIX90 system makes reporting fast and easy with intuitive report creation that repeatedly produces smart and sophisticated reports based on pre-defined templates. Editing is simple and reports can be exported to MS Word or PDF. In addition, the OLYMPUS CIX90 system’s reporting function enables digital zooming and magnification on acquired images. Report files are sized for data exchange by email. |

Predefined Templates

List of available report templates | All available templates are clearly listed. |

Supported Standards

Report templates according to the selected standard | A list of available templates is displayed based on the standard used during analysis. |

Various Output Selection

The software supports output formats such as MS Word or PDF.

Sample Information Area

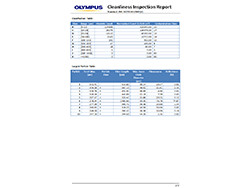

The information page of a report | This area of the report consists of information about the sample such as customer, examiner, order number, and date of inspection. All data are inserted automatically. |

Classification Table

Because the largest particles detected during the scan are of high interest, this report section lists the ten largest particles found during the inspection. | This section of the report incorporates the data calculated during the inspection according to the standard used and displays information such as size class and range information, as well as the absolute numbers of particles detected and the contamination class. |

Images of Largest Particles

The result page showing images of the largest particle | Thumbnails of the largest particles are displayed together with the particle parameters and the particle class. Thumbnails also show images of contaminants reconstructed by stitching smaller images together. |