Brake pad

Background

Brake pads decrease the rotation of a wheel by applying a frictional force against both sides of a disk on the wheel. This subjects the brake pads to stress and elevated temperatures. Depending on the material composition, manufacturing method, and strength of the pads, cracks may develop during use.

Application challenges

Detecting and defining cracks is an important part of quality control. Cracks are usually inspected by observing them through a microscope. However, brake pad materials generally are not good at reflecting the light projected by a microscope’s illuminator. Therefore, ordinary brightfield observation often is not an effective method for detecting brake pad cracks.

The Olympus solution

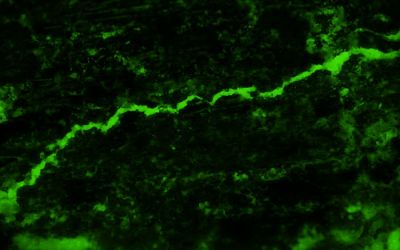

Brake pad cracks can be observed using an Olympus digital microscope with fluorescent capabilities.

Olympus digital microscopes can be equipped with fluorescent filters capable of emitting ultraviolet light. By applying a fluorescent agent to brake pads, cracks are permeated by the agent. When illuminated by ultraviolet light, the cracks are subsequently clearly visible through the microscope.

Product features

- The microscope’s graphical user interface (GUI) enables users to easily switch between brightfield and fluorescent observation.

- Advanced focusing functions provide clear images of the overall field, despite the presence of superficial irregularities in the pad material being observed.

- The automatic stitching function creates a single composite image of the pad material, which displays cracks over an extended distance.

- An integrated measurement function can evaluate the length and width of cracks.

- Areas of interest can simply be enlarged on the GUI by using power-zoom optics.

Images

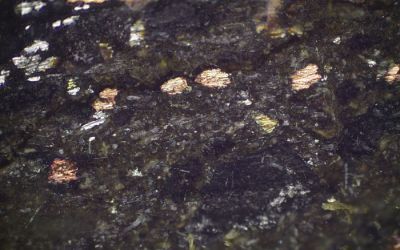

Example of a brake pad that is worn after use

Brightfield image (10x objective lens)

Fluorescence image (10x objective lens; excitation light set to B state)