Our customers use their Vanta™ handheld X-ray fluorescence (XRF) analyzers to determine the material chemistry of alloys, metals, and other materials, but did you know that you can also use your analyzer to measure the thickness of a coating? Vanta analyzers with Coating Method functionality can measure the thickness of coatings on metals, plastics, glass, and even wood.

|

| An automobile being painted. |

Benefits of using XRF for coating measurement

Accurate thickness measurements help manufacturers deliver quality products while also controlling costs. Coatings should be only as thick as they need to be to do their job; creating products with coatings that are too thick increases manufacturing costs. Customers also measure coatings for quality control on incoming materials by making sure that what they’re receiving is coated with the right materials and at the right thickness.

Using a tool that is fast, efficient, and nondestructive helps provide quality control both on the product line and in the field. A Vanta analyzer can provide test results in as little as 10 seconds, and the results can be refined with a one point calibration shot that can be completed in just 30 seconds. Handheld XRF also does not damage the material being tested. Because the analyzer is small, portable, and handheld, it’s easy to test large samples that would otherwise have to be cut to fit into a benchtop analyzer.

Coated materials are everywhere

|

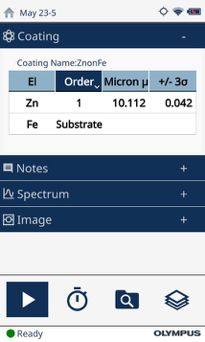

| A thickness measurement

on a Vanta analyzer. |

Coatings can serve a decorative, protective, or other functional purpose. For example, the automotive industry uses coatings for corrosion resistance, decoration, wear resistance, and to protect electronics. Similarly, the aerospace industry uses coatings that help minimize drag and prevent debris and build-up, saving on fuel consumption.

Coatings are so common because most have important benefits. Nickel is tough, durable, and ductile, making it a popular coating material. According to the ASTM recommended standards for quality finishes on steel, approximately 10 microns of nickel should be used on toasters, waffle makers, rotisseries, and similar appliances. For moisture resistance, nickel is applied to stove tops, furniture, bathroom accessories, and cabinets. Another popular coating, chromium, is similar to nickel but provides greater resistance to corrosion and abrasions.

Other common applications for coated material include:

- Shielding electronics: conductive coatings are used to help shield plastic equipment

- Architectural finishes: coatings protect iron and steel from rust, copper and brass from tarnish, and zinc and aluminum from stains

- Solar cells: many solar cells have thin alloy or polymer coatings

- Tool steels: titanium and tungsten carbides help increase wear resistance and durability

- Electrical wiring: zinc and nickel coatings are replacing older cadmium coatings

How XRF measures coatings

The Vanta handheld XRF analyzer can measure coating thickness from 0.00 to approximately 60.00 microns, depending on the material. X-rays are emitted from the analyzer, and they strike the sample, causing it to fluoresce. The analyzer detects the returning X-rays and uses the data to calculate the thickness of the coating or coatings.

According to ASM International's Surface Engineering for Corrosion and Wear Resistance, various surface engineering techniques that fall within this range are plating (mechanical, electroless, electrolytic), vapor (chemical, physical deposition), and bonding (resin or lacquer).