OLYMPUS Inspector Series

Produits non poursuivis

Vue d’ensemble

The OLYMPUS Inspector Series provides accurate and reproducible particle size and distribution data in accordance with International Standards for quantifying residue on filters, advanced particle analysis and non‐metallic inclusion rating and is customizable for internal company standards.

- Automated & Accurate System Solutions

- Automating Typical Inspection Tasks

- Focus On Ease of Use

- Accurate and Reproducible: The Particle Detection

- Classification According to Standards

- Digital Documentation

- A Series of OLYMPUS Inspector

Automated and Accurate System Solutions

Product reliability and quality assurance is the focus for 21st century manufacturing and the acquisition of accurate and reproducible metrology data a top priority. Olympus expertise in imaging and metrology systems provides today's manufacturers with an experienced technology leading partner to provide solutions for particle counting, sizing and classification. The practical application of the particle size and distribution can directly impact the performance, life-time and reliability of many manufactured products. Current applications of OLYMPUS Inspector Series range from quantifying residual particulates on automotive components to analyzing defects and rating non-metallic inclusions in steel.

Olympus offers three different microscope-based turn key systems providing automated high throughput image analysis solutions: OLYMPUS Filter Inspector for automated residue analysis of circular filters; OLYMPUS Particle Inspector for advanced automated particle analysis; and the OLYMPUS Inclusion Inspector for automated rating of non-metallic inclusions in steel.

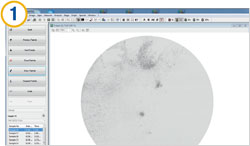

To quantify particles with high efficiency and reliability for manufacturing, quality control or in research and development laboratories, you need to process a high number of images both accurately and quickly. The OLYMPUS Inspector Series has been developed to provide accurate and

reproducible measurement results. Each system consists of the dedicated particle detection software, an Olympus microscope, digital camera, motorized stage with controller and PC.

To quantify particles with high efficiency and reliability for manufacturing, quality control or in research and development laboratories, you need to process a high number of images both accurately and quickly. The OLYMPUS Inspector Series has been developed to provide accurate and

reproducible measurement results. Each system consists of the dedicated particle detection software, an Olympus microscope, digital camera, motorized stage with controller and PC.

The systems are designed to provide you with an intuitive workflow from acquisition through standardized documentation. Accuracy of results is guaranteed with the use of motorized focus capabilities, a dedicated particle standard calibration slide and latest image analysis techniques. In addition, accuracy is validated post scan through go-back-to-particle function, driving the stage to the exact location of the particle in question.

OLYMPUS Filter Inspector Analysis of residue requires the determination of the number of residue particles on the entire filter. | OLYMPUS Particle Inspector Manufacturing defects like pores or blowholes influence the mechanical properties of materials. | OLYMPUS Inclusion Inspector The quality and properties of steel are highly depended on the non-metallic inclusions in steel. |

Automating Typical Inspection Tasks

Acquire Image

| Image acquisition is integrated in a simple workflow that reduces errors and improves reliability. Integrated tilt-compensation and predictive focus algorithms during the scan guarantee focused images. |

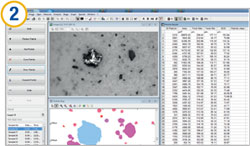

Process Results

| The frame-independent multi-image detection ensures full reconstruction of particles at image borders and a particle size independent image analysis from a few microns up to several millimeters. |

Analyze Data

| The OLYMPUS Inspector Series offers a selection of multiple complex particles (fibers, reflecting particles, stringers or globule) as well as the capability to create your own particle selection method. |

Create Report

| The OLYMPUS Inspector Series integrates a complete report tool for professional reporting without any user interaction and a powerful data management tool for automatic archiving and retrieval of data. |

Focus On Ease of Use

Single Source Solution

Olympus provides all software and hardware components, seamlessly integrated to provide highly accurate, fast and reproducible measurement results, as well as making standardization of inspection equipment for multiple sites efficient and straightforward.

Predictive Software and Laser Autofocus

The laser autofocus unit is a fast, repeatable option for surfaces with low contrast. | OLYMPUS Inspector Series offers an integrated tilt compen-sation, that extrapolates the tilt of the sample, either linearly or non-linearly, during the scan. A laser-based autofocus can be integrated with the microscope's motorized focus to automatically lock in focus in real-time, ensuring all detectable particulates are properly in focus. |

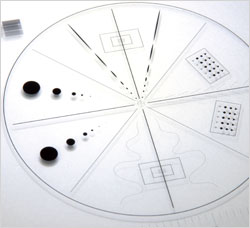

Performance Verification

Particle Standard | To ensure accurate measurements, Olympus offers a particle standard designed to verify system calibration for various particle shapes and sizes. |

Accurate and Reproducible: The Particle Detection

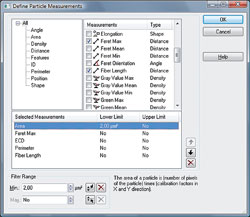

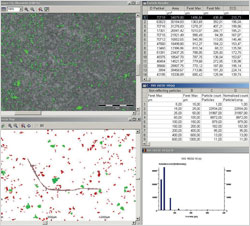

Powerful Particle Detection Engine

An extensive list of parameters for frame-independent particle analysis. | The OLYMPUS Inspector Series possess a powerful, fast and accurate frame independent multi-image detection of real particles, based on the gray level threshold together with a comprehensive set of morphological parameters. More than 100 standard parameters are implemented. |

Flexible Particle Identification

Direct particle identification. | To maximize efficiency, particles are detected immediately which gives you direct access to particle identification of fibers, reflecting and non-reflecting particles, stringers or globular particles. Moreover, the particle height can also be measured on manually selected objects. |

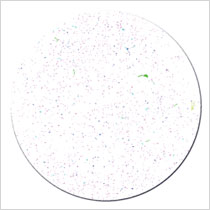

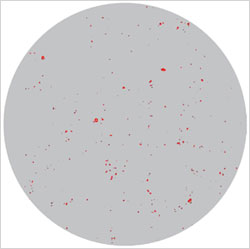

View Your Entire Sample

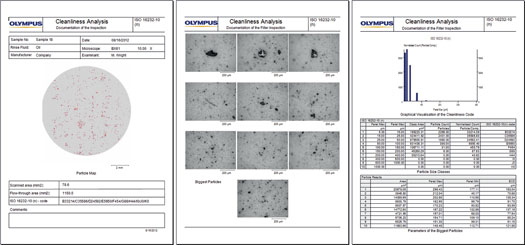

Automatically generated output documents. | The OLYMPUS Inspector Series reconstructs the entire sample and creates a complete particle map, independent of sample size. This image can then be used in a report, as required by national and international standards. |

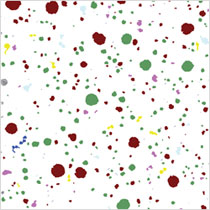

Display and Monitoring Results

Classification in accordance with all established standards. | The system automatically creates several standard documents: automatic acquisition of the largest particles, article result sheet, display of the particles in colors associated with the size classification and a particle map representing the whole sample. |

Classification According to Standards

Compliant with Industry Standards

The mandatory regulations for counting and classifying contamination are defined in corresponding international,

national, or company standards for the respective branches of industry such as ASTM, ISO, or JIS. With its extensive data

mining capabilities the OLYMPUS Inspector Series classifies the data according to these standards and norms. It is also

possible to create user-defined rules that can be utilized by customers or internal regulations.

Classification in accordance with all established standards. | Cleanliness Standards ISO 4406:1987, ISO 4406:1999, ISO 4407:1991, ISO 16232, NF E 48-651, NF E 48-655, NAS 1638, SAE AS4059 Non-metallic Inclusion Rating in Steel ASTM E 45, EN 10247, DIN 50602, ISO 4967, GB/T 10561, NF A 04-106, UNI 3244, JIS G 0555 |

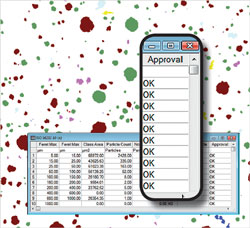

Approval Flag

Automatic approval of the results with a 'OK' or 'Not OK' designation. | The integrated approval test of the OLYMPUS Inspector Series software minimizes the time to determine if the part has passed or failed inspection. The system automatically assigns an 'OK' or 'Not OK' flag to a particular size class according to the user-defined limits of the measurement values and/or code numbers. This integrated approval test gives users a deeper view into the results, saving both time and money. |

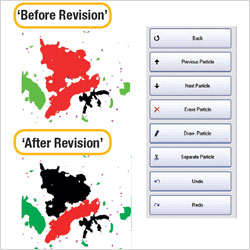

Revision and Re-Classification

User-assisted revision of detected particles | The revision mode gives direct access to each detected object. You can easily separate, delete and draw particles, or perform a complete re-classification. The OLYMPUS Inspector Series provides the ability to comply with internal company standards. It is also possible to re-process the existing data using different parameters or create a new classification scheme. Revision and re-classification are a no-risk operation. |

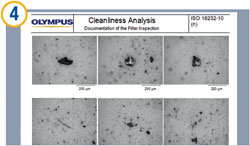

Digital Documentation

Reporting

The OLYMPUS Inspector Series integrates a complete report solution for professional reporting. Reports are automatically generated with all the relevant measurement results for the standard selected and report content can be fully customized to match the user's requirements.

The integrated report tool generates standardized documentation automatically based on standard or customized templates.

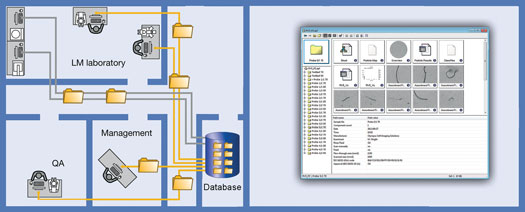

Archiving

The OLYMPUS Inspector Series integrates a powerful data management tool for automatic archiving and retrieving of all documents including images and data files. The database can be modified to suit the specific requirements and offers many advantages, including the ability to re-examine stored samples if new or updated standards are available.

All documents can easily be archived with all corresponding image and data files in the integrated database.

A Series of OLYMPUS Inspector

OLYMPUS Filter Inspector

Cleanliness analysis on filter media. | Filter residue analysis is an essential part of analyzing cleanliness for liquids and high precision parts. Detecting, visualizing, identifying and reporting residual particles found on filter media help automotive and aerospace engineers quantify contamination, that in turn affects the performance, lifetime and reliability of final products. Microscope-based residue analysis helps determine the size of particulate contamination down to the micron level. Particles are measured and then classified in compliance with relevant standards. |

OLYMPUS Particle Inspector

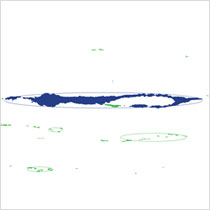

Particle inspection is of interest for advanced material research applications. | The OLYMPUS Particle Inspector addresses the need for advanced image analysis in addition to classical particle detection and analysis. The integrated focus-mapping function improves particulate detection and measurement accuracy for advanced materials with varying topographies. |

OLYMPUS Inclusion Inspector

Steel microstructure with superimposed reference image as overlay for live evaluation. | The purity of steel depends highly on the content of non-metallic inclusions coming from the production process. Reliable and accurate monitoring of these non-metallic inclusions is an important quality factor as demand for high quality steels rises every year. OLYMPUS Inclusion Inspector provides a reliable and accurate analysis and rating of non-metallic inclusions in steel, without tedious manual observation work. |