Ceramic Parts, Coatings

Ceramic Parts, Coatings

New techniques in the manufacture of ceramics have led to many new high-performance and heat resistant ceramics that have found increasing use in the automotive, aerospace, and electronic industries.

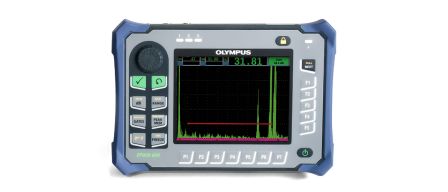

Most structural and electronic ceramic components are well suited for ultrasonic thickness gaging. Fired ceramics can generally be measured over a wide thickness range and with a great degree of precision. Ultrasonic gages can be used to measure the thickness of structural ceramic products such as turbine blades, valves, and other engine components. Elastic modulus can also be calculated through measurement of longitudinal and shear wave velocities.

In addition to basic wall thickness measurements, ultrasonic gages can measure ceramic coatings on most substrates. Ultrasonics is also a technique well suited the nondestructive detection of flaws, irregularities, and bond integrity in ceramic parts and components.

Because of the wide variety of physical properties in ceramic materials, it is recommended that a sales engineer be consulted for final selection of instrumentation.