This application note explores how to measure liquid levels in a container or pipe using the noninvasive method of direct level measurement. It also explains how to detect the presence or absence of liquid in a sealed container using the presence/absence test.

Methods for Measuring Liquid Levels

The simplest method of measuring liquid level is by direct observation using a dipstick or calibrated float. However, this method is not appropriate in some instances where a sealed container cannot be opened or its contents cannot be exposed to air. Ultrasonic liquid level measurement is often a good solution for situations that require fast, automatic measurement of the level in a large number of containers that are going through a filling process.

Ultrasonic liquid level measurement is also useful for the following areas:

- Measuring levels of caustic or reactive fluids in chemical processing applications where containers cannot be opened for safety reasons, and the nature of the chemical or the process prevents installation of an internal float gauge.

- Detecting the presence of standing fluids in a pipe, particularly to investigate pipes that are being opened or cut during maintenance procedures.

- Checking assembly line fluid levels in a variety of automotive components, such as fuel tanks, transmission assemblies, engine oil pans, and differentials, in which a fast and reliable noninvasive measurement is required. In some cases, the gauges are used in conjunction with an automated manipulator to position the transducer for online measurement of filled containers. The outputs of the gauges are used to activate paint sprayers to mark containers whose fill level is out of tolerance.

- Measuring a layer of oil floating over a layer of water in a petroleum processing system. In principle, it is possible to measure any single layer of liquid in situations where a liquid of different acoustic impedance floats on top of a second liquid.

In general, liquid level applications are divided into two categories: those requiring measurement of actual liquid level (depth or height), and those requiring detection of the presence or absence of liquid at a selected point. Both tests are described separately in the sections below.

Equipment Used for Direct Level Measurements

Liquid level is generally measured by conventional pulse-echo thickness gauging techniques, using standard ultrasonic thickness gauges or flaw detectors where greater range is required. Transducers are selected on the basis of particular application requirements but will usually be 1 MHz or 2.25 MHz. We recommend any of the following instruments:

- 39DL PLUS™ and 45MG thickness gauges with Single Element software can be set up for liquid level measurement. They provide high/low alarms and data storage for recording and documentation, in addition to a digital display. The measurement range is typically up to approximately 5 in. or 125 mm.

- EPOCH 650™ and EPOCH 6LT flaw detectors can measure very long liquid paths (potentially greater than 4 ft or 1.25 m).

For any of these instruments, range and accuracy are determined by specific test conditions and must be quoted on an individual case basis. Accuracies of ± 0.1 in. (± 2.5 mm) are possible in most liquids.

Procedure to Take Direct Level Measurements

The liquid level in a container is measured by coupling the transducer to the bottom of the container using couplant. An electrical impulse is transmitted from the thickness gauge to the transducer generating a short ultrasonic sound pulse, which is transmitted through the container wall and into the liquid. The pulse travels up through the liquid until it reaches the surface where it is reflected and returns through the liquid to be received by the transducer.

The echo from the liquid surface is precisely timed from an electronic zero time point that subtracts transit time through the container wall. The round-trip transit time of the pulse is converted to the liquid level by making the following computation electronically:

h = vt/2

Where:

h = liquid level

v = sound velocity in the liquid

t = round-trip transit time

The liquid level is shown on a digital display. Certain factors as listed below must be considered to make this measurement technique effective.

- Container material type and thickness: Consider these factors first in relation to the fluid properties and level range. Thick-walled steel containers may seriously limit the minimum level that can be measured due to wall ring down effects. Plastic containers have acoustic properties similar to many liquids and therefore provide efficient transfer of sound from the transducer to the liquid, minimizing ringdown.

- Surface condition of the container wall: Corroded or pitted container surfaces may distort the transmission of the sound pulse and make it difficult or impossible to measure.

- Curvature of the container: Sharply curved containers may distort the sound pulse or cause inadequate coupling of the transducer to the container, preventing reliable measurement.

- Obstructions: The sound path between the bottom of the tank and the top of the liquid must be free of physical obstructions like baffles or fill pipes.

- Acoustic properties of the liquid: The degree of ultrasonic attenuation in the liquid often determines the maximum level measurement. Generally, high viscosity liquids and liquids with high concentrations of solids are most attenuating to ultrasound.

- Temperature effects: Temperature changes in liquid cause changes in the sound velocity of the liquid. If the instrument's velocity calibration is not readjusted to compensate for these velocity changes, the level readout will be incorrect.

- Gas bubbles: Bubbles of air or other gasses will scatter sound waves and can produce false readings or prevent any readings at all.

- Motion of the liquid surface: The liquid surface must usually remain motionless in the container to produce a readable surface echo.

- Liquid composition: The liquid must have uniform composition and temperature for accurate measurements.

- Coupling of the transducer to the container wall: Adequate coupling of the transducer to the container wall is necessary for the sound pulse to be transmitted from the transducer through the container wall and into the liquid.

Equipment Used for Presence/Absence Measurement

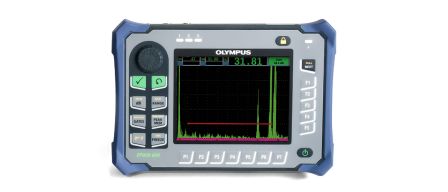

We recommend using a flaw detector such as the EPOCH series, all of which are suitable for pulse-echo presence/absence measurement. The type of transducer used will depend on the type of liquid and the sound path length.

Procedure to Take Presence/Absence Measurements

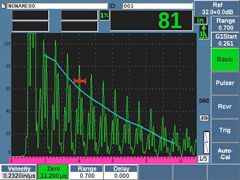

The specific test setup depends on the application. In general, we recommend a simple pulse-echo test when the application involves a container or pipe whose geometry permits transmission of an ultrasonic pulse across a column of liquid and reception of an echo from the far wall. Absence or presence can be indicated by visual or audio alarms. In the pulse-echo mode, the signal from the transducer is coupled into the container wall. If liquid is present at the point of measurement, a portion of the sound energy will travel through the liquid and reflect off the opposite wall of the container, traveling back through the liquid and through the container wall into the transducer. If no liquid is present, there will be no backwall echo, although there will be some echoes generated by the container wall that is in contact with the transducer. Low-frequency contact transducers are usually used for this test. In the figure below, a 2.25 MHz contact transducer is coupled to the wall of a steel tank approximately 45 mm (18 in.) wide. The echoes at the left side of the screen represent multiple reverberations in the tank wall, and no echo is present within the red gate. |

|

By setting a gate at the point in time where the echo from the far wall is expected, the operator can monitor the status of the liquid. If liquid is present, there will be an echo detected within the gate, as seen in the right figure.

In certain situations, the pulse-echo method cannot be used. When there is no clear sound path between the front wall and the back wall, liquid monitoring must rely on the ringdown method. This always requires a smooth, clean container surface for uniform transducer coupling. In this method, the instrument identifies changes in the echoes from the wall onto which the transducer is coupled. The effect is much like a ringing bell, suspended in air in one case and immersed in liquid in the other. Liquid will damp out the sound energy much more quickly than air. Similarly, the instrument "listens" to the type of echo and draws a pattern that can be used by the operator to determine the presence or absence of a liquid at a particular point. |

|

This type of test is normally performed with a delay line transducer. The figures below represent a typical ringdown test on a steel tank using a V206-RB delay line transducer (5 MHz). The upper waveform represents the echo ringdown pattern from a liquid-backed wall. The DAC function has been used to trace the echo envelope. The lower waveform shows the larger echoes received from an air-backed wall, where the damping effect of liquid on the inside surface is no longer a factor. By moving the transducer up and down the side of the tank and looking for the transition point between these two patterns, the operator can identify the point representing the top of the liquid contained inside.

|

|