The health of the environment is important, and a significant part of making our world safer involves making our world green. For many people, recycling is an easy way to help the environment, and it begins with placing plastic, paper, and glass into their respective curbside bins. For glass, in particular, it can be endlessly recycled with no loss of purity, and recycling it saves on raw materials, reduces the demand for energy, and helps cut CO2 emissions. However, glass recycling requires more than separating bottles by color. In fact, not all glass is the same, and separating it correctly can be a challenge.

Glass Recycling

Glass is recycled in a closed-loop system (meaning that it’s recycled back into glass), which saves raw materials needed for the creation of new glass. The environmental benefits of glass recycling are particularly advantageous because, unlike plastic, glass can be reused and recycled indefinitely, provided it contains no contaminants.

Unrecyclable glass materials such as ceramics, crystal, and clay garden pots are increasingly common in a variety of products including cookware, manufactured goods, and smartphones, and can contain contaminants—including lead—that are harmful to our health. Even if no harmful contaminants are present in the unrecyclable glass, most have different chemistries and a higher melting point than regular glass, which can potentially cause damage to the glass furnace and cutting systems and create impurities in new glass material. When an average of 33% of new glass containers consist of recycled glass, it’s especially important to separate contaminated waste from the recyclable glass. To make recycling practical, these materials need to be separated out using a fast, affordable, and reliable system. |

The Recycling Process

In modern single-stream recycling, all the recyclable material gets dumped on a conveyor, where it undergoes a multistep separation process. Paper, ferrous, nonferrous metals (like aluminum), and glass can all be reliably separated. At the end of the process, the glass is crushed into small pieces called cullet. The cullet moves on to the reclaiming facility where unrecyclable glass needs to be removed. Historically, glass recyclers may utilize magnetic or visual/infrared sorting, but there are some drawbacks to these methods. For example, ceramic glass and recyclable glass have similar physical properties and are distinguished only by their chemistry. So, how do we efficiently separate safe, recyclable glass from unsafe materials? |

The Answer: X-Ray Fluorescence (XRF)

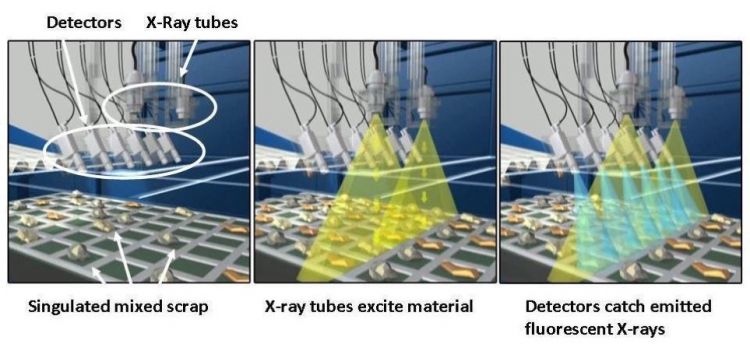

XRF is a technology that can be used to determine the material chemistry of a sample. The advantage of sorting glass using XRF is its ability to detect and separate the contaminated glass fragments from recyclable glass by chemical composition. For example, a handheld XRF analyzer (HHXRF) can recognize ceramic identifiers such as zinc, titanium, and lead in fragments of material as small as 1 mm (0.04 in.) in diameter, which then can be manually removed from the safe, recyclable glass. However, a glass recycling plant can process more than twenty tons of cullet per hour, making manual separation of the identified unrecyclable glass impractical. Fortunately, XRF can be scaled to high-speed, in-line systems.

Our X-STREAM™ in-line X-ray fluorescence analyzer can process as much as twenty-eight tons of glass cullet per hour, is designed for high volume, and uses multiple detector arrays so that even small fragments can be reliably separated. The X-STREAM: Glass sorts glass cullet as it passes under the arrays and separates contaminated fragments from safe glass using a blast of air. With the contaminated glass separated from the recyclable glass, the endless cycle of glass recycling can safely continue.

Related Content

Does this Glass Pass? Using XRF to Screen for Ceramic and Lead Contaminants