Introduction

The analysis of wear metals or additives in lubricating oils and contaminants in fuels is crucial to the proper maintenance and functioning of many types of machinery. Heavy transportation and trucking, mining, aircraft, military, and marine equipment all have increasingly stringent testing requirements. Machine operators across many fields have a vital need for fast and accurate analysis of fuel and lubricating oils. Olympus has developed the Vanta™ handheld XRF analyzer and its oil analysis method to meet these requirements with high speed and minimal sample preparation. The Vanta XRF analyzer can provide operators real-time, on-site analysis and measure key wear metals—such as copper (Cu), iron (Fe), nickel (Ni), and chromium (Cr)—as well as several secondary or regulated metals, such as manganese (Mn), molybdenum (Mo), mercury (Hg), and cadmium (Cd). The Vanta analyzer can also measure the concentration of key fuel additives—including phosphorus (P), sulfur (S), calcium (Ca), and zinc (Zn)—in accordance with ASTM D6481. With routine testing provided by the Vanta analyzer, operators can identify small issues before they become costly failures.

Wear Metal and Secondary Metal Analysis

Wear metals analysis is one of the most effective ways to detect potential machine failures before they become serious and expensive. Metallic elements in engine and lubricating oil can help predict potential failures, as well as aid in identifying the failing component. Early and fast detection of elevated metal concentrations is vital to making such testing effective. There are also several secondary metals—including alloying elements like Mo and Mn and hazardous heavy metals like Hg and Cd—that operators typically monitor. These elements are indicators for both engine performance and regulatory compliance. In a matter of seconds, an operator can analyze for thirty-one separate elements to quickly identify potential failures in engine systems.

Oil Additive Analysis

To protect precision equipment operating under extreme temperatures or heavy loads, top quality lubricants depend on specially formulated blends of organometallic additives. These additives extend lubricant life, protect metal surfaces, and increase the range in which a lubricant can be used. Additive elements such as calcium and zinc contribute to key lubrication characteristics, while elements like sulfur and phosphorus are essential for extreme pressure lubricants. A robust maintenance program that routinely measures metals and additives in lubricating oils not only reduces the expense of routinely dismantling the components for visual inspection but also helps indicate and identify the worn component before it fails. ASTM D6481 provides guidance on monitoring these additive elements for potential depletion. The Vanta handheld XRF analyzer’s capabilities in sensitivity and repeatability are effective in accomplishing the criteria set by this standard.

VCA Model Oil Repeatability Comparison

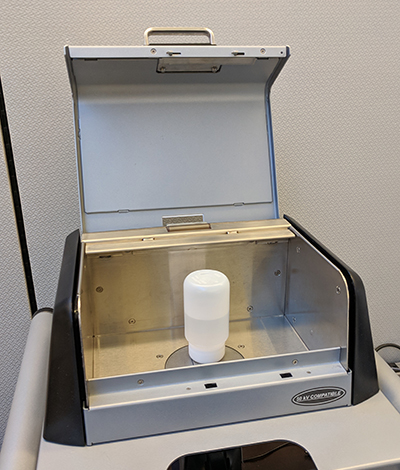

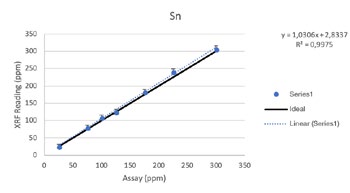

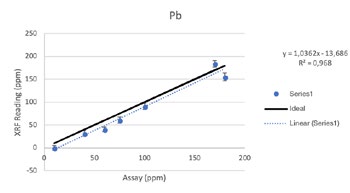

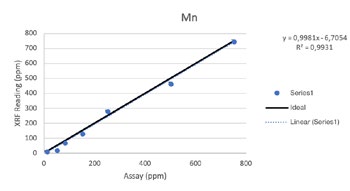

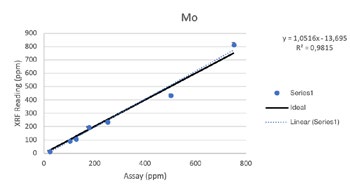

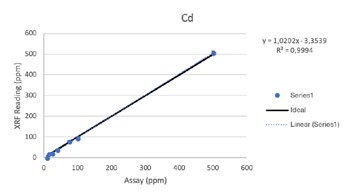

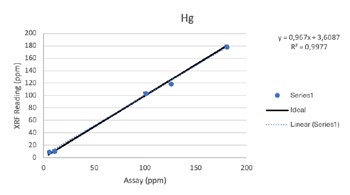

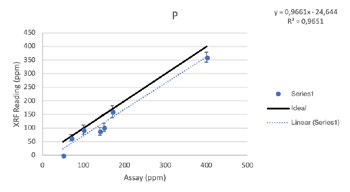

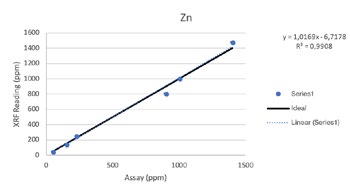

Vanta XRF Analyzer PerformanceTo demonstrate the Vanta analyzer’s performance capabilities, we tested several certified oil samples with various levels of wear metals, secondary metals, and additive elements, using a VCA model (Vanta C-series silver anode analyzer). Samples were collected as is in plastic bottles with Prolene® windows for XRF measurement. The measurement results shown are the averages of five repeated tests compared against the lab assay value. |  |

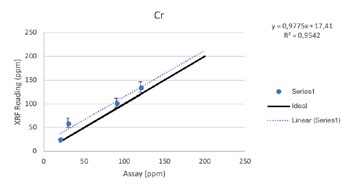

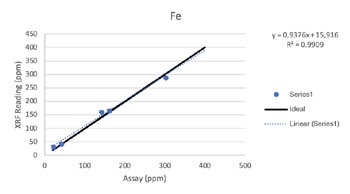

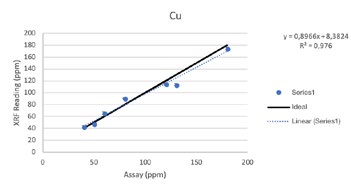

Wear Metals

|  |

|  |

|  |

Secondary Metals

|  |

|  |

Additive Elements

|  |

|  |

Oil analysis is prone to high variability because of the heterogeneous nature of metals in oil. Interelemental effects can also impact the accuracy and sensitivity of various transition metals and additive elements. Despite these limitations, the Vanta analyzer was able to test all the above elements with high repeatability and consistency (R2>0.95 for all elements). Trend lines were within 5% of the lab assay for wear metals and secondary metals and within 16% of the assay values for additives.

Conclusion

The Olympus Vanta handheld XRF analyzer can effectively and accurately measure wear metal and secondary metal content at low-ppm levels for accurate monitoring of engine oil. The Vanta analyzer can also test for fuel additive elements in accordance with ASTM D6481. Vanta XRF provides an effective combination of sensitivity, performance, and ease of use, helping give machine and engine operators the confidence they require.