Olympus propels eddy current technology into uncharted territory in the aerospace industry, with an innovative surface crack detection solution for lap-splice inspection. The structure of an aircraft contains thousands of fasteners, so ensuring their integrity can be an arduous process. Conventional inspection techniques are typically very time consuming and the probability of detection is highly dependant on operator skill. Nevertheless, for over a decade the technology has remained relatively stagnant ... until now.

Using eddy current array considerably reduces the duration of an inspection, and detection probability is increased. This solution not only saves man-hours, but its streamlined inspection process helps minimize the possibility for error.

Features

- Time-savings: up to ten times faster than EC pencil probe inspection, and up to 15 times faster than PT inspection.

- Avoids paint removal; faster and more streamlined process.

- Probe positioning not as critical as pencil probes or sliding probes.

- Omnidirectional detection.

- Great reproducibility.

- Already integrated into Boeing inspection procedures (757 Part 6 53-30-12).

- Intuitive and easy-to-read imagery.

- Data recording for professional reports.

- Replaces magneto-optical imaging (MOI).

High Resolution Scan

The recommended ECA probe, the SBBR-026-300-032, is 26 mm (1 in.) wide and features 32 coils arranged in two rows. This configuration provides increased resolution and clear imagery, which is suitable for very high resolution scans. Its small coils (1.6 mm diameter) and high frequency (80–1000 kHz) allows operators to detect very minute cracks. It can also be used to scan through thin coatings, including standard paint thicknesses. Crack orientation is irrelevant for this probe, as its detection is omnidirectional. Scanning is also effective over ferromagnetic fasteners.

SBBR026-ENC probe kit

Scan Through Thick Coating

Another probe is available that can scan fasteners through thick non-conductive coating: the SEB-064-005-032. Though it does not provide high resolution like the SBBR-026-300-032, its low-frequency range (0.5–50 kHz) and bigger coils can scan through thicker, nonconductive coatings like paint, stickers, and rubber. Due to its large coverage (64 mm), two rows of fasteners can be scanned at one time. And, cracks do not have to be oriented in a specific direction, as this probe is also omnidirectional.

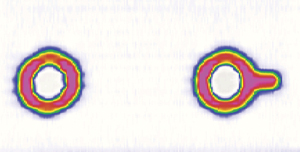

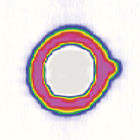

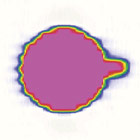

Intuitive imagery

Sample with EDM notch |

C-Scan |

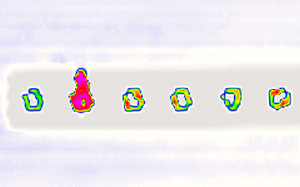

Performance for different notch lengths

1.5 mm

|

2.5 mm

|

4 mm

|

4 mm

|

Omnidirectional detection

No coating |

2.5 mm of nonconductive coating |

SEB064-ENC probe kit