The Importance of Weld Inspection

The quality of welds is becoming increasingly important as customer expectations rise. Products and components are expected to be of a high quality and not to fail unexpectedly.

Such failures have large financial and social consequences that can often be avoided with the proper inspection techniques.

Inspecting welds can also reduce costs by detecting defects in the early stages of manufacture, reducing the cost of customer returns and extending the life of components by detecting and correcting any defects.

Eddy Current Non Destructive Testing is a reliable, quick and inexpensive way to carry out preventative maintenance and ensure safety. Our eddy current equipment has a world-wide reputation for its reliability and accuracy, while our service and support ensure that you make the most of your equipment.

Eddy Current Testing on Welds

In welding inspection there is a need to detect surface breaking defects. For magnetic material e.g. carbon steel, generally magnetic particle inspection is used. However, eddy current inspection offers a number of advantages:

• No consumables used - e.g. ink & contrast paint.

• Ability to test areas with poor access.

• No surface preparation required - e.g. paint doesn't need to be removed, saving time in preparation for the inspection and in any recoating of surfaces .

• Improved sensitivity - ability to detect smaller defects using specially developed Weld Probes.

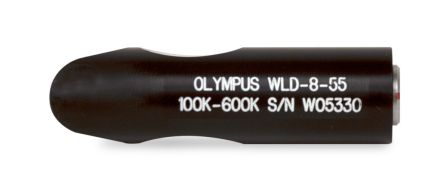

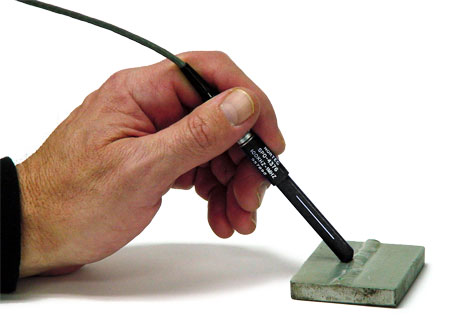

Weld Probes

The Weld Probe has been specifically developed to check welds for cracks and corrosion. Examples of areas where it is currently used include:

• Offshore platforms

• Buildings

• Bridges

• Amusement park rides

• Ships, boats, submarines etc.

• Cranes

• Utility poles

• Aircraft

Weld Probes have been designed to be extremely hard-wearing so that they can handle the rough weld surface while still picking up any faults in the weld.

NECP-1152L 45° Stainless Shaft Weld Probe