Analysis of coal using Olympus portable X-ray fluorescence (XRF) analyzers provides engineers with quick and accurate estimates of the ashing content (ash yield) and critical elements, such as sulfur. This information can be used to minimize shutdowns and improve the efficiency of maintenance activities.

Ash and Sulfur Evaluation in Coal-Fired Power Plants

In coal-fired power plants, it is important to know the amount of ash that will be produced during the coal combustion process as well as the sulfur content of the coal. This is because ash, which is rich in sulfur and phosphorous, can stick to the walls of the furnace, causing it to degrade.

Using Vanta Portable XRF to Estimate the Ash-Forming Material in Coal

Vanta portable XRF analyzers can be used on coal feed material to quickly and accurately estimate:

- Ashing content (ash yield)

- Sulfur content

Using this information, power plants can:

- Reduce the frequency of plant shutdowns by developing more appropriate coal blending strategies

- Increase productivity by planning maintenance activities in advance, since engineers can use the composition data of incoming coal to predict when shutdowns and maintenance may be required

- The Vanta analyzer automatically calculates the level of the ash-forming material, so users can quickly estimate the ash yield of their coal in near real time

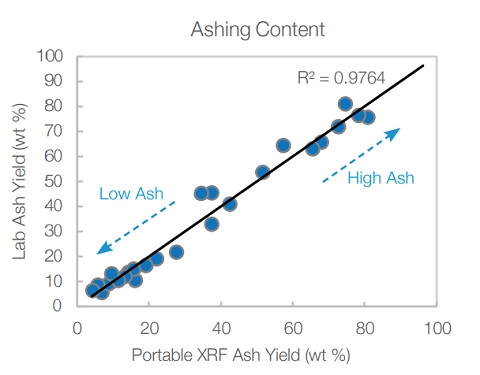

Figure 1. Olympus XRF analyzers provide excellent estimates of ashing content (ash yield) using a combination of light elements (Mg + Al + Si + P + S+ Ti + K + Ca + Fe). Data courtesy of School of BEES UNSW—ACARP Project Number C24025. |

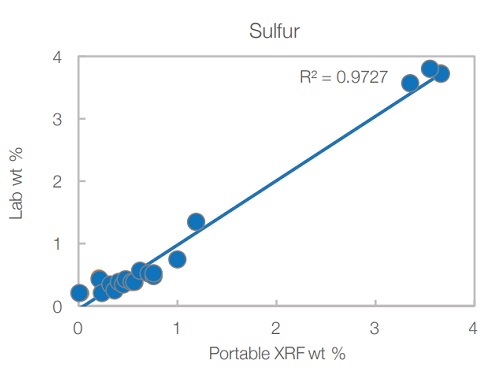

Figure 2. Excellent correlation between sulfur measured by portable XRF (x-axis) compared to coal certified reference materials (y-axis). |

Benefits of Vanta™ XRF Analyzers

Power generation plants can be hot, dusty environments. The Olympus Vanta XRF analyzer is able to operate in harsh working environments with features that include:

- Continuous operation at high temperatures up to 50 °C (122 °F)*

- IP55/IP54 rated to withstand dirt, dust, and rain

- Rugged—built to pass a 4-foot (1.2 m) drop test (MIL-STD-810G) to help prevent breakages

- Cloud data storage and real-time remote data viewing using the Olympus Scientific Cloud™