One of the oldest methods of modern transportation, the history of rail dates back nearly 500 years. With an expansive and aging infrastructure, railroads require constant support to maintain their integrity and operate safely.

Many types of nondestructive testing (NDT) techniques have been used to help ensure the quality of both the rail and the many components that make up a rail car. These methods range from the so-called “car knocker,” which uses acoustic resonance to detect cracked wheels, to the “oil and whiting” test used for fatigue crack detection in steam locomotive pins and axles. Currently, ultrasonic testing (UT) is the preferred method of NDT in the railroad industry.

Ultrasonic testing uses high frequency, directional sound waves to measure material thickness, find hidden flaws, or analyze material properties. UT requires the use of a transducer that transmits and/or receives the ultrasound signals being passed into the metal and a flaw detector to process the results. While UT is used in a range of applications, it is especially important for rail testing.

Rail Testing

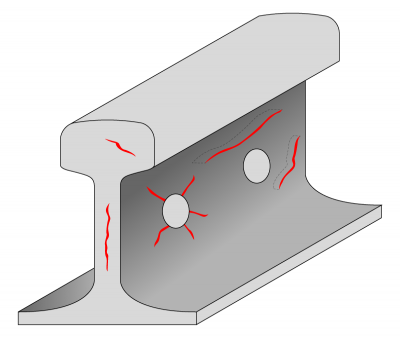

Over time, rails can develop discontinuities originating from either a manufacturing defect or from in-service use. These discontinuities can be disastrous if they go undetected and must be monitored through scheduled maintenance or safety programs. Today, the majority of rail testing is performed using the “chase car process,” consisting of a lead test vehicle that performs flaw detection that’s followed by a verification chase car. When the lead test vehicle encounters a potential flaw, the location is communicated to the chase car. It’s the chase car operator’s responsibility to verify if a defect exists and report any positive findings to the railroad for remedial action.

Another common rail testing method is the “portable test process,” which consists of an operator pushing a mobile test device over one rail individually or both rails simultaneously (at a walking pace) while visually interpreting test data on a monitor. Both the chase car and portable test methods utilize straight beam and angle beam transducers to detect possible flaws or discontinuities within the rail.

Detecting Discontinuities

Typical service-induced discontinuities that occur in rail sections are head and web separation, horizontal split head, detail fracture, transverse fracture, engine burns, shelling, and bolt hole cracks. Head and web separations, as well as horizontal split heads, can be easily detected using a UT flaw detector with a 2.25 MHz / 0.50 in. straight beam transducer (such as our A106S) positioned over the rail centerline. By observing the returned signal, head and web separations can be confirmed through the loss of the back echo, which represents the reflection of the UT signal off the base of the rail.

Bolt-hole and transverse discontinuities are typically detected using 2.25 MHz / 0.50 in. angle beam transducers (such as the A540S paired with the ABSA-5T-X). Bolt-hole cracks tend to propagate at a 45-degree angle, making them particularly sensitive to detection when using a 45-degree angle beam transducer. Detecting transverse discontinuities and detail fractures, however, requires angle beam transducers with higher refraction angles (typically 60 to 80 degrees). Detectability improves for discontinuities that are angled downward in the same horizontal direction as the flow of heaviest traffic.

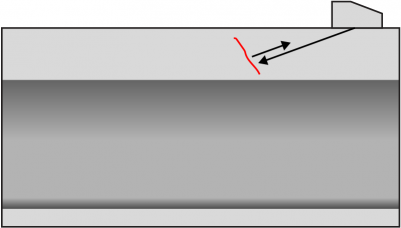

A side-skewed angle beam transducer operating in through-transmission is particularly effective for locating detail fractures. The transducers are nominally 60-degree angle beam types with the transmitting transducer skewed toward the gage side of the rail by 30 degrees and the receiving transducer located next to the gage side of the rail. With this arrangement, a signal arriving at the receiving transducer indicates a rail with no discontinuities. An interrupted signal would indicate a discontinuity. For maximum detection reliability, angle beam scanning must be applied in both directions.

Conclusion

Ultrasonic testing provides a fast, reliable way to inspect rails as well as the many components that make up rail cars. This technology helps keep the world’s rail systems operating smoothly and safely.

Get In Touch

.jpg?rev=911C)