Application

Detection of laminar cracking in fiberglass structures, tanks, pipes, boat hulls, wind power blades, and similar applications.

Background

Because of its laminar layup structure, fiberglass is potentially subject to cracking parallel to the surface, either because of applied stresses or weaknesses resulting from manufacturing anomalies. These hidden internal cracks can have a significant impact on structural integrity and are normally not detectable by radiography or NDT techniques other than ultrasonics.

Ultrasonic flaw detection offers a simple method for locating internal voids. High-frequency sound waves coupled into the part by a small probe called a transducer will reflect from cracks and voids in a predictable way. Ultrasonic waves will travel through a material until they encounter a boundary, such as a far wall, but if there is a crack within the sound path, it will generate an additional echo where there should not be one. By observing echo patterns on a display screen, a trained operator can quickly and reliably verify material integrity.

Equipment

Any of the EPOCH® series flaw detectors can be used for this test, including the EPOCH 650 and EPOCH 6LT instruments. The type of transducer used in a given test will depend on the specific part geometry and thickness. The specialized M2008 delay line transducer (0.5 MHz, 1 in. diameter), designed for optimum performance on thick fiberglass and composites, is normally recommended for thicknesses greater than approximately 12.5 mm or 0.5 in. For thinner fiberglass, the M1036 contact transducer (2.25 MHz, 0.5 in. diameter) is commonly used.

Procedure

Ultrasonic flaw detection is a comparative process in which the echo pattern generated by a good part is compared with the echo pattern from a test piece. Since sound waves will reflect from voids or cracks, changes in the echo pattern indicate changes in the internal structure of a part. In testing fiberglass, the operator typically looks for the presence of echoes within a marked gate or window that represents the interior of the test piece. While the inhomogeneous nature of fiberglass frequently generates scatter noise reflections even from solid material, cracks whose area approaches the diameter of the sound beam typically return strong localized indications that will be recognized by a trained operator.

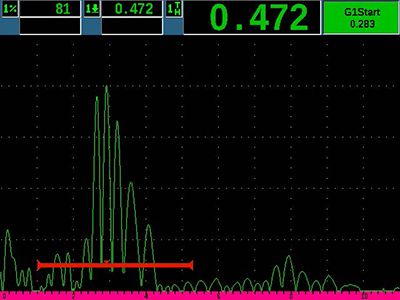

The example below shows detection of a large laminar crack void in a 50 mm (2 in.) thick fiberglass tank wall, using an EPOCH® 650 flaw detector and a 500 KHz transducer. The transducer is coupled to the top of the part. With a good part, the sound travels to the bottom surface and creates a reflection from a depth of 2 in. That is the peak at the right side of the image in the waveform below (left). But when a crack is present, the sound will reflect from the crack and create a peak within the zone on the screen that is marked with the red gate, representing the middle of the part. The presence of a strong echo in that area indicates a large discontinuity in the part. The inspection takes only a few seconds per test point.

|  |

Typical indication from good part  | Typical flaw indication, echo in red gate  |

A similar test can be applied to most types of fiberglass structures and parts. For further information, contact Olympus.