Calibration Certification

Calibration certification is the process of documenting the measurement accuracy of a thickness gauge under specific test conditions. Manufacturer's calibration certification is usually performed with thickness reference standards whose thickness is traceable to the National Institute of Standards and Technology (NIST). Measurement accuracy under documented test conditions is typically compared with the manufacturer's established tolerance for a given gauge, transducer, gauge setup, and material.

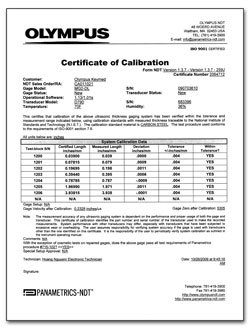

It is important to note that ultrasonic gauges must always be certified as part of a system that includes the transducer as well as the gauge setup, since the measurement accuracy of any ultrasonic gauge is dependent on the performance and proper usage of both the gauge and transducer. A calibration certificate is only a record of gauge performance under the stated conditions, using a specific transducer. System performance with other transducers may vary, especially transducers that have been subject to wear or overheating. Additionally, use of the gauge on materials other than the reference standards used for calibration certification will require a new velocity recalibration. If that process is performed incorrectly, inaccuracies will result. It is the responsibility of the user to verify measurement accuracy to whatever level they require for a given test. This is usually easy to do by simply checking readings with proper reference standards of known thickness.