Conventional Transducer Construction

To understand how phased array transducers work, it is helpful to first consider the conventional monolithic ultrasonic transducers designed for NDT applications.

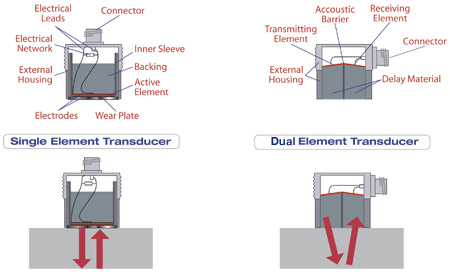

These transducers come in a wide variety of sizes, frequencies, and case styles, but most have a common internal structure. Typically, the active element of the transducer is a thin disk, square, or rectangle of piezoelectric ceramic that converts electrical energy into mechanical energy (ultrasonic vibrations), and vice versa. It is protected from damage by a wearplate or acoustic lens, and backed by a block of damping material that quiets the transducer after the sound pulse has been generated. This ultrasonic subassembly is mounted in a case with appropriate electrical connections. Common contact, delay line, immersion, and angle beam transducers utilize this basic design. Dual element transducers, commonly used in corrosion survey applications, differ in that they have separate transmitting and receiving elements separated by a sound barrier, no backing, and an integral delay line rather than a wearplate or lens.