Last updated on June 25, 2024.

If you are one of the millions of people who wear contact lenses, an ultrasonic thickness gauge may have helped their manufacturer ensure that your lenses are the proper shape and thickness for your prescription.

Shortly after soft contact lenses were introduced in the 1970s, we developed a pioneering ultrasonic system that quickly and reliably measures the thickness and radius of curvature of soft lenses. Our current version of this specialized system is used by some of the world’s major contact lens manufacturers.

How Soft Contact Lenses Are Made

Most soft contact lenses are made in a multistep process using specialized polymers that undergo transformations from a liquid to a solid and then to a soft, strong gel.

In the first step, the liquid polymer is formed in a mold that shapes the radiuses and determines the thickness. The liquid is then hardened, either by curing with ultraviolet light or by cooling. The result is a hard lens which is then soaked in a warm saline solution. The polymer absorbs water, softens, and takes its final shape. Some specialized lenses are formed individually by machining a disk of hard polymer on a lathe and then softening it by the same soaking process.

Manufacturers need to verify lens thickness and curvature on a statistical sample of their production. This is difficult to do with mechanical tools; because the lenses are soft and flexible, they will be distorted by contact. This is where ultrasonic testing comes in.

Non-Contact Ultrasonic Testing of Contact Lens Thickness

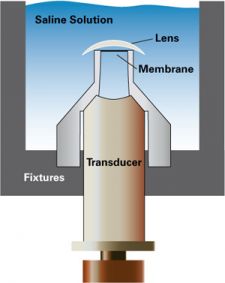

The solution we created is a non-contact ultrasonic test. The lens is positioned in a fixture filled with saline solution and centered over an ultrasonic transducer that generates a sharply focused sound beam. A 39DL PLUS™ precision thickness gauge detects echoes from the near and far sides of the lens, measures the time interval between them, and uses a programmed sound velocity to calculate lens thickness to an accuracy of +/- 0.01 mm.

At the same time, the gauge measures the distance between a reference membrane and the base of the lens (a dimension called sagittal height) and uses a simple mathematical formula to calculate the lens’ radius of curvature.

You can read more about this process in our application note, Base Curve and Thickness Measurement of Soft Contact Lenses. This is yet another way ultrasonic gauges help our customers maintain manufacturing quality.

Related Content

Ultrasonic Thickness Gauge Tutorial

Base Curve and Thickness Measurement of Soft Contact Lenses

.jpg?rev=8156)