Waveguides are important aerospace-related components installed on satellites (especially geostationary satellites) to transmit radio frequency (RF) signals with low loss and high power. These hollow metal tubes are necessary components for microwave and satellite communications.

In this post, we explore the challenges of inspecting the metallic pipes inside waveguides and share the capabilities of ultra-thin borescopes for effective waveguide inspection.

Challenges of Inspecting the Metallic Pipes Inside Waveguides

Waveguides have a dedicated tubular structure for high-frequency signal transmission. If burrs or dirt are left inside the waveguide during the waveguide manufacturing process, the waveguide won’t function correctly and signal transmission will be inefficient. This may affect communication with ground stations and coordination with other satellites.

In addition, since satellites use a variety of sensors to monitor their surroundings, a faulty waveguide can affect the sensors and cause erroneous data to be collected. This can lead to problems in attitude and orbit control.

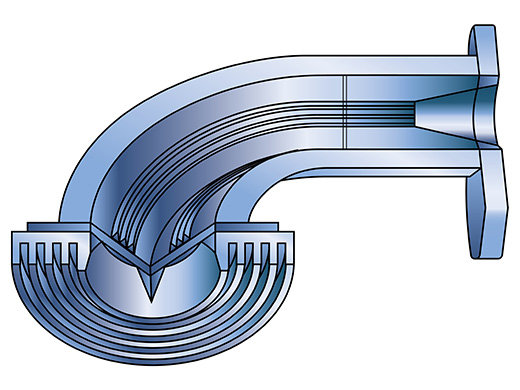

As a waveguide’s components must accurately function and efficiently transmit signals, internal inspections are critical. Any defects in the inner wall surface of the metal tube that transmits high-frequency signals can’t be overlooked (Figure 1).

Figure 1. Cross section of a waveguide.

When performing internal inspections of waveguides used in satellites, a standard borescope can have difficulty accessing the interior of the metallic tube. The diameter of the metal tubes used for satellite waveguides is about 3 mm to 5 mm. In comparison, the insertion portion of a borescope typically has an outer diameter of 6 mm or 4 mm, which is too large to easily access the inside area of a waveguide. This is where ultra-thin video

borescopes come in.

Borescope Capabilities and Techniques for Waveguide Inspection

A video borescope with an outer diameter of about 2 mm is recommended for internal inspection of waveguides as it can easily access the space.

In addition to a small diameter, the flexibility of the scope is important to maneuver through tight bends in the pipe. Waveguides may be in the simple form of thin straight lines or the more complex form of metal tubes with bends and branches.

Therefore, we recommend using an ultra-thin video borescope that can be inserted to accommodate the branches and bends of pipes. An articulation function helps the scope follow the bends and branches of metal pipes.

Another factor is durability, as the outer diameter of the insertion portion of an ultra-thin video borescope is smaller than that of a standard borescope. As a result, the outer braid of the scope may be damaged by rubbing against the inner wall of the metal tube or by contact with the edge or branching portion of the metal tube.

In particular, the articulation section of the scope is the part that’s most vulnerable during inspection. It’s essential to select an ultra-thin video borescope with a highly durable articulation structure.

To avoid missing any defects inside the metal pipe, we recommend selecting an ultra-thin video borescope with a wide 120-degree viewing angle and a large adjustment range for brightness settings. These features let users observe images of a wide observation area on a large monitor screen and adjust the brightness to see more during the inspection.

Learn More about Ultra-Thin Video Borescopes

One example instrument that offers these capabilities is our IPLEX™ TX II ultra-thin video borescope. With a small diameter scope, a durable articulation section, and a wide viewing angle with adjustable brightness, it is a highly capable instrument for detecting defects inside a waveguide. This visual inspection further improves the reliability of waveguides, one of the most important aerospace components onboard satellites.

To learn more about imaging in small spaces with borescopes, check out the video below. You can also reach out to us anytime with questions or to request a demo.

Related Content

Brochure: IPLEX TX II Video Borescope

Aviation Borescopes for Aircraft Inspection

Visual Inspection of Part Defects: Methods, Challenges, and Opportunities