Periodic maintenance of nuclear power plants are critical health checkups that keep equipment running safely, prevent issues from arising, and help ensure safe and stable operation. To inspect complex parts of nuclear power plant equipment, we offer remote visual inspection solutions for primary systems (nuclear islands) and secondary systems (conventional islands).

Areas Where Visual Inspection Is Required

Select a button to see the remote visual inspection details for that part.

| ① Turbine② Steam Generator③ Reactor Vessel④ Condenser⑤ Pipes |

|---|

Our Solution

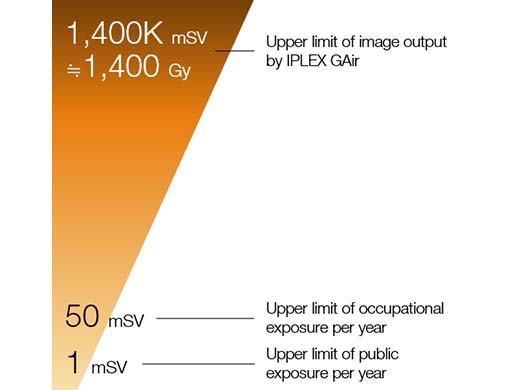

Radiation-Resistant DesignThanks to the rugged design of the LED illumination, the IPLEX NX and IPLEX GAir insertion tubes are resistant to high levels of radiation. They can deliver images even after being exposed up to 1,400 Gy* radiation doses, withstanding radiation exposure that far exceeds the established safe limits for workers. *Results for to the IPLEX GAir, based on research by Evident at a third-party facility. Please ask your Evident representative for details. |

Source: ICRP, 2007. The 2007 Recommendations of the International Commission on Radiological Protection. |

Fast and Accurate MeasurementAchieve fast and accurate measurement of cracks and corrosion with ease using the advanced stereo measurement capabilities of the IPLEX NX video borescope. 3D modeling enables you to see the details of your target from multiple angles, making it easier to specify the exact location of your measurement points. |

|

Replaceable Scopes for Inspection EfficiencyQuickly swap out the insertion tube without any special tools, using the interchangeable scope feature of our IPLEX GAir, IPLEX NX, and IPLEX GX/GT video borescopes. If an insertion tube becomes contaminated with radiation, save time and reduce costs by replacing the original scope with a spare. |

See Clearly from a Safer DistanceFor visual inspection of hazardous areas, maintain a safer distance using the video borescope's remote operation feature. With an optional transponder system, the IPLEX GAir video borescope can be controlled from up to 100 m (328 ft) away. This enables you to set up the IPLEX GAir system in one area and remotely operate its functions from a different location. You can also share live images of the inspection with offsite colleagues using the USB wireless LAN adapter.* *Using a recommended third-party USB wireless adapter. |

Precise Articulation Regardless of LengthThe IPLEX GAir video borescope’s pneumatic articulation system driven by air pressure provides fine control of the tip angle regardless of the unrolled scope length. Simply pull out the scope length needed for your inspection—up to 30 m (98 ft)—and maneuver the insertion tube. The pneumatic articulation is compact with an integrated air compressor for easy transportation throughout the plant. |

Know Your LocationThe gravity sensor automatically rotates live images regardless of the scope’s orientation, while the insertion length indicator tracks the insertion tube position within a pipe. These IPLEX GAir video borescope features help ensure that you always know which direction is up on the display, and you can identify the exact location of a defect within a long pipe. This information makes your follow-up inspection using flaw detection or thickness gauging equipment more efficient. |

Wide Range of ChoicesWhatever your borescope inspection needs are, we offer a long inspection camera with the right combination of features. With lengths from 2 meters (6.5 feet) to 30 meters (98 feet) and a range of advanced functionalities, choose the long video borescope that best suits your application. |

|

Learn More about Our Solutions

Blog Post Keeping a Safe Distance: Mitigating Radiation Exposure for Nuclear Plant Inspections Using Video Borescopes | View Blog Post |  |