Overview

Introduction to Visual Inspection Measurement SolutionsAdvances in 3D Stereo Measurement |  |

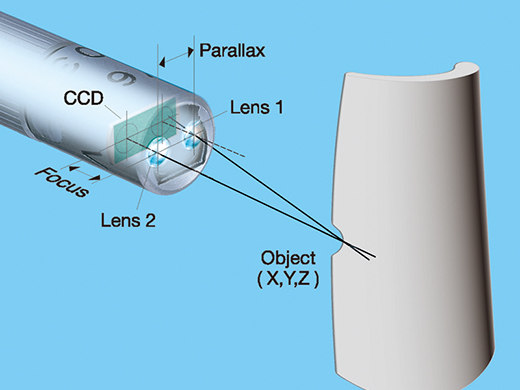

About 3D Stereo MeasurementWhat Is Stereo Measurement?Stereo measurement is an inspection technology based on parallax—the change in position of an object from two vantage points—to quantify small defects that can affect the function and safety of equipment. A videoscope built with this technology can quantitatively analyze defects for reliable visual inspection. Paired with the right optics, stereo measurement enables you to quantify defects in a three-dimensional space with any tip-to-target angle and defect type. |

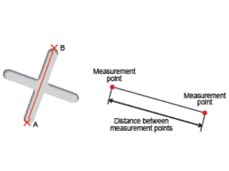

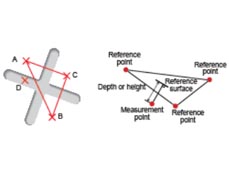

How Does Stereo Measurement Work?Pointed at the same target, the stereo lens system sees a subtle change in the target’s position with respect to the left vs. right lens. Parallax enables us to acquire the X, Y, and Z positions of each pixel from the target to calculate length, depth, and area. A videoscope with a stereo measurement lens system follows four steps to quantify flaws:

|

Watch this video to learn the stereo measurement principle. |

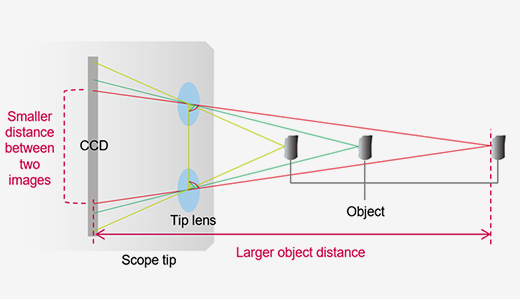

The Correlation Between Object Distance and Measurement AccuracyIncreased object distance causes lower measurement accuracy. The reason is that if an object is too far from the scope tip, the images transmitted onto the CCD through the two lenses will be placed too close to each other for measurement.

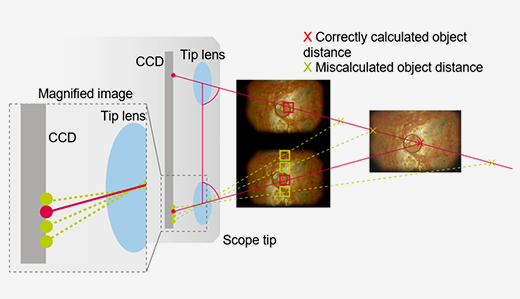

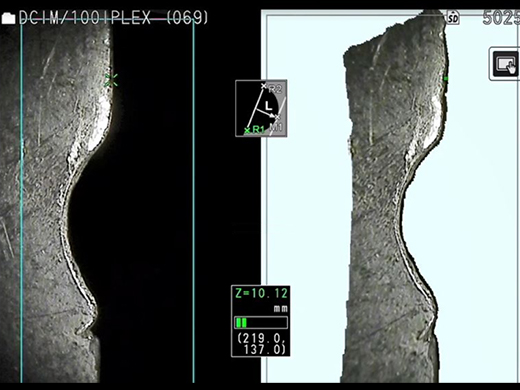

| Pixel Matching on the CCD/ImageThe ability to correctly match pixels is critical for measurement accuracy. Mismatching of the same target pixel between the left and right stereo images indicates a false representation of reality, causing an incorrect measurement result.

|

The Benefits of Advanced Stereo MeasurementThe advanced stereo measurement capabilities in Olympus IPLEX™ NX, GX/GT, and G Lite videoscopes benefit inspectors in multiple ways: |

Measure Faster with Multi-Spot RangingTo measure faster is to measure once and obtain the most reliable result. The quality of stereo measurement results depends on the optimal tip-to-target distance, and modern videoscopes like the IPLEX NX can provide a real-time tip-to-target distance in a 3D space before you even start to perform a measurement. This function, called Multi Spot-Ranging, enables faster and more accurate measurement results. IPLEX GX/GT and G Lite videoscopes have a Single-Point Spot Ranging feature that works the same way as the IPLEX NX model. |

|

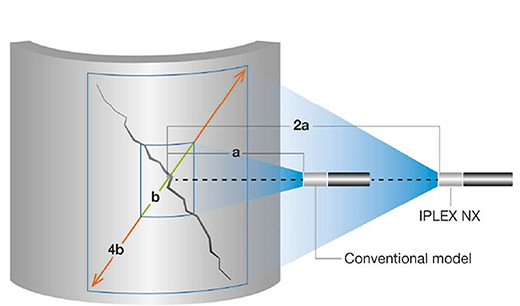

Get a Higher Probability of DetectionAn expanded field of view and depth of field mean you can see and measure defects from farther away compared to conventional scopes, giving you a higher probability of detection. After all, you can’t measure what you can’t see. |

Expanded measurement capabilities on our IPLEX NX industrial videoscope (4b) enable detailed measurements from greater distances (2a). |

3D Modeling for Accurate MeasurementsEven with advanced stereo measurement capabilities, accurate and precise measurements still depend on how precisely you set reference points and measurement points. Setting these parameters can be challenging in certain situations, such as measuring parts with complex scenes, difficult lighting conditions, and irregular surfaces. So, how do modern videoscopes enable precision in point selection? The answer is 3D modeling. For instance, the 3D modeling feature on our IPLEX NX videoscope makes it easier to visualize the precise shape of critical components. It gives you an enhanced knowledge of the target with various 3D views in addition to the standard 2D stereo images. |

|

To learn more about 3D modeling, check out the blog posts below: How to Confirm Videoscope Measurement Points with Confidence

|

|

|

| |||

|

|

|

|

|

|

3D Stereo Measurement FAQsHow can I confirm that the measurement points are accurately placed?Since stereo measurement technology is based on parallax, you can visually confirm whether the point is in the right position using two separate windows. You can also use the zoom function to get a closer look. Various 3D modeling views also enable more accurate placement of measurement points. How can I create better 3D models?To create a better 3D image, avoid strong reflection or halation by adjusting the illumination level and angle of the distal end to the target. Is it possible to re-measure images taken in the past?Yes. For every stereo measurement recorded, the videoscope records a screenshot of the measurement result and records the stereo image, which can then be remeasured on the videoscope or with our InHelp™ PC software. Can you re-measure on a PC?Yes. Use the free InHelp Viewer software to measure on your PC. Simply transfer the stereo image using any method to perform the re-measurement. Visit this link to download the InHelp Viewer software. How can I improve measurement accuracy with stereo measurement?Measurement accuracy can easily be affected by a target’s surface or image capturing conditions. In general, the closer you can approach the target, the better the accuracy. The Spot Ranging feature on IPLEX NX, GX/GT, and G Lite videoscopes is a useful tool to help you determine the optimal tip-to-target distance in real time. |

Learn More about Olympus VideoscopesWe offer a series of videoscopes with advanced stereo measurement features. Explore the videoscope models below to learn more: |

|

|

|

Need Assistance with Measurement Solutions?Contact Us |