The high demand for product reliability and quality assurance puts pressure on manufacturers to quickly obtain reliable cleanliness data. Yet, technical cleanliness inspections can be difficult to perform without the right equipment—especially for novice operators.

Read on to learn the challenges of technical cleanliness inspections and find out how our OLYMPUS CIX100 cleanliness inspector makes them easier.

The Challenges of Technical Cleanliness Inspections

Technical cleanliness inspections can be challenging to perform for a number of reasons: users must regularly review results during inspection, view multiple particles at the same time, and revise results for different standards.

This all must be done as fast as possible—and sometimes while production is running. Not to mention, the results must be shared quickly in a format compliant to industry and company standards, as well as stored right away for later reference.

Our OLYMPUS CIX100 system is a turnkey solution that helps solve these challenges with an intuitive workflow. Users of all experience levels can quickly and easily acquire, process, and document technical cleanliness data to meet industry and company standards.

Here are some of the system features that simplify cleanliness inspections:

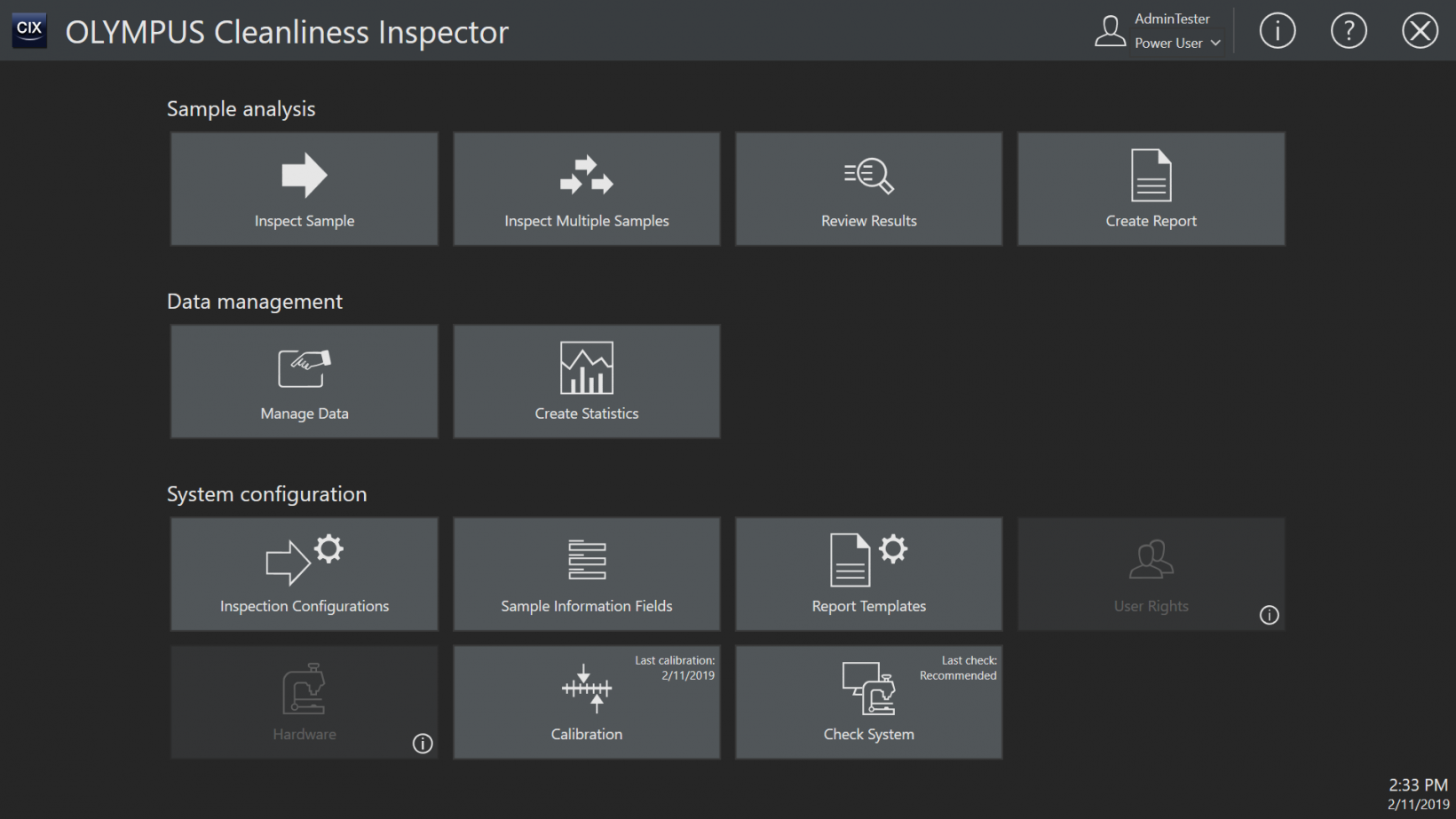

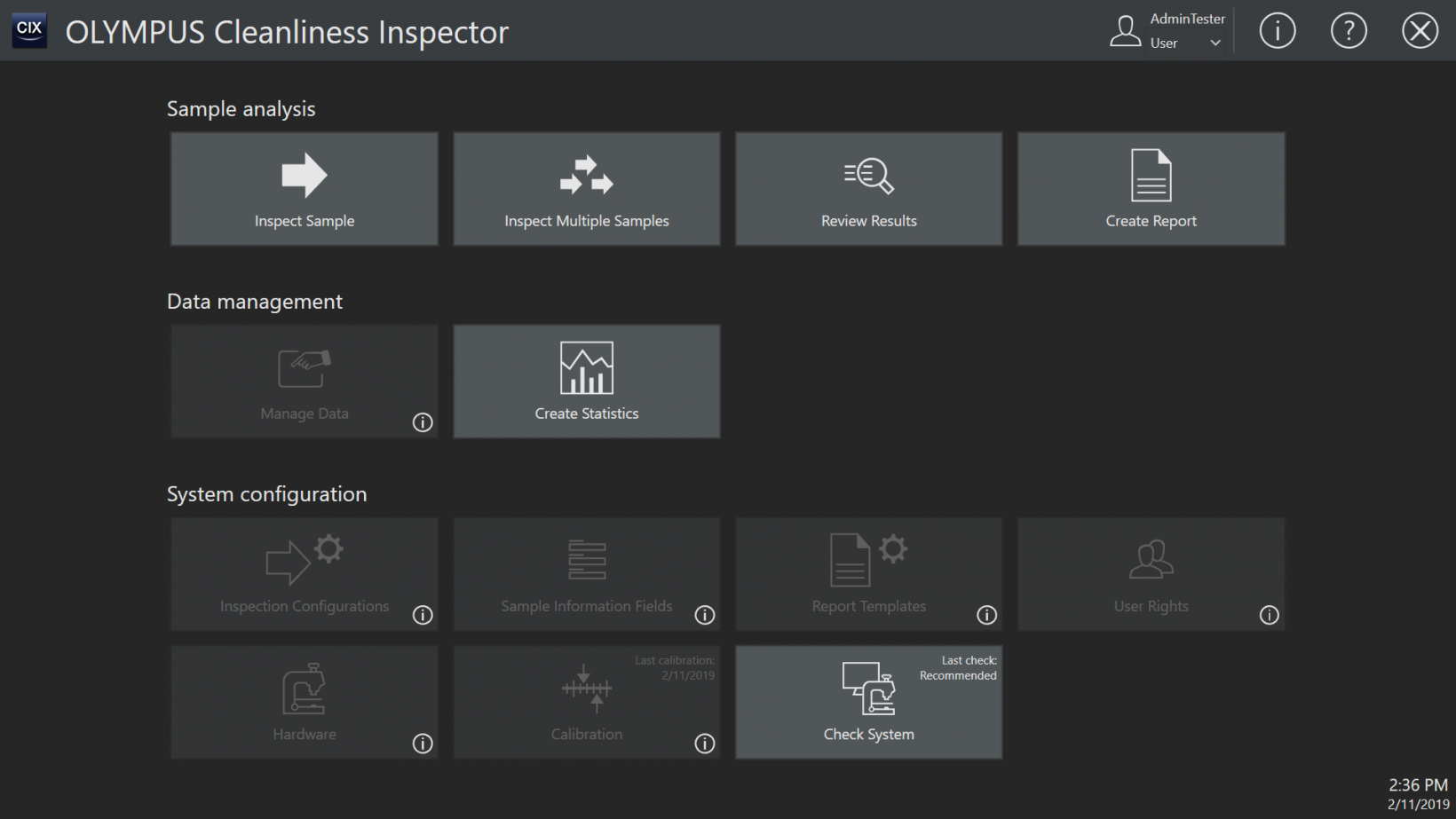

Tidy user interface with guided workflows.

First, our OLYMPUS CIX100 system is equipped with a neat and organized user interface to simplify the particle analysis workflow. The interface guides users through the complete inspection process in just three easy steps: Inspect Sample, Review Results, and Create Report.

The interface also has large buttons that are easy to click with a mouse or the touch screen monitor, making the workflow as straightforward as using your smartphone. Details can always be found with one click on the help button.

Pre-calibrated and pre-configured system.

The system is also pre-calibrated and pre-configured. Operators can immediately start performing the inspection without the need to adjust settings. Calibration verification is just as simple. The software regularly reminds the operator to perform system self-checks, which is easy to do thanks to the built-in particle standard device.

User rights management tools.

User rights management makes it even easier for operators to stay on task. Power users can limit inexperienced users to basic workflows by restricting certain functions.

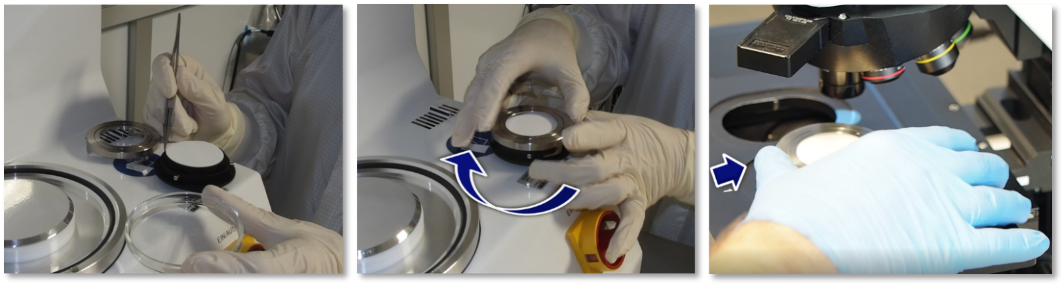

Easy sample positioning on the system.

Another intuitive feature is the easy sample positioning. After sample prep, users only need to place the filter on the microscope stage. The easy-to-use bayonet lock secures the filter holder without any tools, fixing the membrane without stretching or twisting it. The rest of the analysis is performed with full software control.

Maximized automation.

Automation makes analysis easy for users of all skill levels. When the operator begins the workflow, the OLYMPUS CIX100 system uses automation to scan the membrane and analyze the sample. It automatically counts, measures, and classifies particles according to the selected standard.

Users also have fully automated software control of every hardware component, from the nosepiece to the illumination. Not only does automation improve ease of use, but it minimizes human errors and the risk of contaminating the sample.

Thanks to live particle classification, the user can also interrupt the process at any time to immediately take action in case of a failed test. Direct visual feedback shows which particle classes exceed their limits and NOK overall approval, helping to support the operator in this possibly critical situation. Optionally, the system can emit an acoustic warning signal as soon as the safe threshold is exceeded.

One-click review of particles.

The review step is streamlined with the operator in mind. Data, images, and results are clearly organized for efficient analysis.

First, all particles, classification tables, the overall cleanliness code, the particle location, and the standard used appear in one view. You can also find an at-a-glance display of complete inspection data in various selectable views.

For instance, the images of particles are organized from largest to smallest for various types of particles. This means you can visualize all the reflective particles at once or view all the non-reflective particles in another view.

To make data review even easier, the thumbnail images of contaminants are linked with their locations and dimensions. The thumbnail also has a live image link for further analysis with a convenient visual. Selecting a thumbnail automatically drives the system to this contaminant.

Left: With the CIX100 cleanliness inspector, you can visualize particles from largest to smallest in one view. Right: The position of each thumbnail image is linked to the live image, automatically driving the system to this contaminant as soon as it’s selected.

The software also comes with handy tools like delete, split, and merge to make revising the data simple.

Compliant one-click reporting.

Predefined, professional templates make the reporting step easy. With a single mouse click, the system automatically generates a report according to the selected technical cleanliness standard. You can then export it to a Microsoft Word or PDF file depending on your requirements.

Reports are also sized for easy data sharing over email. And, if the predefined template needs to be customized to fit your company regulations, you can easily adapt the template features.

A Turnkey Solution for Technical Cleanliness Inspection

Intuitive features are just one part of the OLYMPUS CIX100 cleanliness inspector. The system is also optimized for reproducibility, compliance, data management, and fast result generation so you can deliver detailed information on particle contamination and meet high standards for technical cleanliness.

Related Content

5 Ways the OLYMPUS CIX100 Cleanliness Inspector Delivers Reproducible Results

Brochure: OLYMPUS CIX100 Cleanliness Inspector

Analyzing Metal Contamination in Piston Rings

Get In Touch