Olympus’ Damien Blondel recently presented at the International WEEE and Battery Recycling Virtual Conference, an event that brings together industry professionals from across the world to discuss trends, insights, and best practices in the electronics and battery recycling industry.

Damien reviewed why portable X-ray fluorescence (pXRF) is a powerful technique to get on-site, fast, and easy chemical composition of a wide range of materials in electronics and battery recycling. If you missed the presentation or want a recap, this post will share highlights and lessons from the talk.

The Positive Benefits of Portable XRF for Electronics and Battery Metals Recycling

Portable XRF is a versatile tool for waste electrical and electronic equipment (WEEE) and battery recycling, including:

- Battery metals identification and quantification

- RoHS compliance testing

- Precious metals testing in electronics

Let’s explore each XRF application for battery metals recycling.

Identifying and Quantifying Battery Metals

pXRF analyzers provide key battery commodity concentrations for these elements:

- Cobalt (Co)

- Nickel (Ni)

- Manganese (Mn)

- Copper (Cu)

- Aluminum (Al)

- Rare-earth elements (REEs)

pXRF instruments such as our Vanta™ handheld XRF analyzers can help optimize the extraction, smelting, and refining processes, as well as reduce the number of lab tests. While pXRF analyzers can’t quantify lithium (Li), portable X-ray diffraction (pXRD) tools such as our BTX™ III or TERRA™ II instruments can complement pXRF and analyze lithium and other key materials in battery metals recycling or battery metal exploration.

RoHS Testing: Screening for Toxic Metals

pXRF analyzers can also screen for toxic metals in many consumer products, including electronics, enabling RoHS compliance.

Screening for toxic metals with the Vanta handheld XRF analyzer

For instance, the Vanta analyzer can screen for:

- Lead (Pb)

- Cadmium (Cd)

- Arsenic (As)

- Mercury (Hg)

- Chromium (Cr)

- Other toxic metals

Portable XRF analyzers are ideal tools for conducting a reasonable testing program (RTP)—a formal testing plan that you develop and follow to comply with regulations that apply to your product. An RTP can help you fulfill requirements for:

- Lead-free compliance in boards, cables, connectors, PCBs, metal components, and solders

- RoHS compliance

Vanta analyzers can be configured to provide RoHS pass/fail results

Precious Metals Testing in Electronics

In addition, pXRF analyzers can quantify precious and valuable metals from materials in circuit boards, connectors, and cables. These metals include:

- Gold (Au)

- Platinum (Pt)

- Palladium (Pd)

- Silver (Ag)

- Copper (Cu)

Precious metals testing using a Vanta analyzer

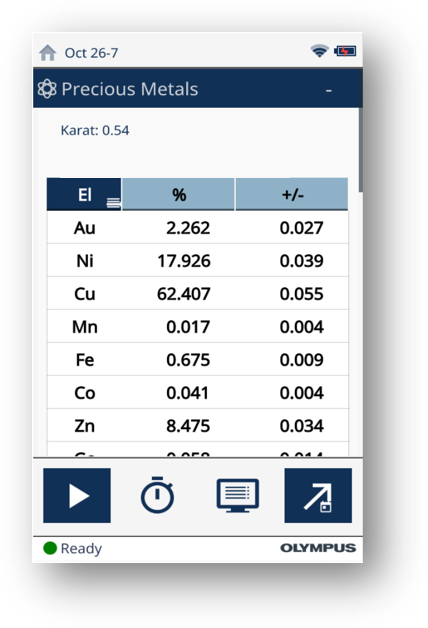

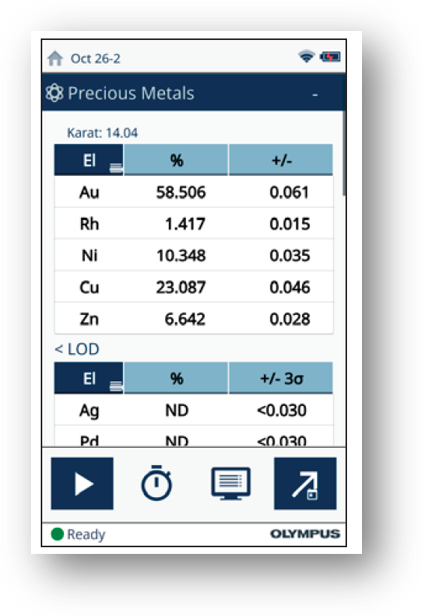

Vanta analyzers give you fast results to help you optimize your precious metals refining process and reduce the number of lab tests. For instance, you can quickly get gold analysis results directly on the analyzer, as shown in the images below.

Vanta analyzers alert you if gold plating is possible

Vanta handheld XRF analyzers identify 14 karat gold quickly and effectively

Why the Vanta Handheld XRF Analyzer Is Ideal for Battery Metals Recycling

Overall, Vanta handheld XRF serves a wide range of applications for electronics and battery recycling, including RoHS and regulatory applications, precious metals testing, and battery mineral testing.

Along with its rapid chemical composition results, the Vanta analyzer’s design makes it an ideal tool for battery metals recycling:

- Low cost of ownership: The Vanta analyzer is built rugged for testing in challenging environments. It also needs minimum maintenance, enabling maximum uptime.

- Designed for user productivity: Modern connectivity and data transfer make the results reporting process easy.

- Accurate chemical composition analysis: Olympus’ proprietary Axon Technology™ processing provides low element limits of detection (LODs) and repeatable tests for reliable results.

Learn more about Vanta handheld XRF to see how it can improve your productivity and deliver a fast ROI.

Related Content

The Role of Handheld XRF in the High-Power Lithium-Ion Battery Supply Chain

The Fault with Cobalt: Overcoming the Challenges of Battery Metal Exploration

Screening for RoHS Substances with XRF

Get In Touch

.jpg?rev=9096)