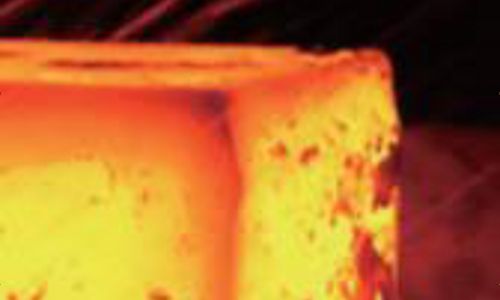

Metallic materials can be considered the most important inorganic engineering materials due to their excellent electrical conductivity and mechanical properties, such as tensile strength, fatigue strength, and ductility. These materials also show high flexibility in terms of their mechanical properties, as they can be adjusted through heat treatment or composition changes. Metallic materials are usually made by combining metallic elements, such as iron, titanium, aluminum and gold, with a small amount of nonmetallic materials, such as carbon, nitrogen and oxygen.

Common metal alloy classes include:

- Stainless steel, such as 316L

- Titanium-based alloys, such as Ti-6Al-4V, which is commonly used in the medical, automotive, and aerospace industries

- Nickel-based alloys, such as IN718 and IN625 used in the aerospace industry

- Aluminum alloys, such as AlSi10Mg used in the aerospace and automotive industries

Material Microstructural Properties

According to the industry, alloy type, and application, certain mechanical and microstructural properties are required for a product to perform safely in specific operational and environmental conditions.

The following analysis methods are commonly performed for microstructural and morphological inspections on metallic parts and materials to check their quality before and after manufacturing processes.

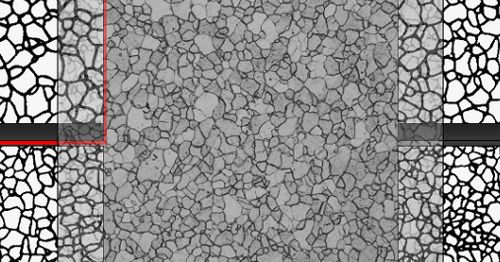

- Determination of grain size

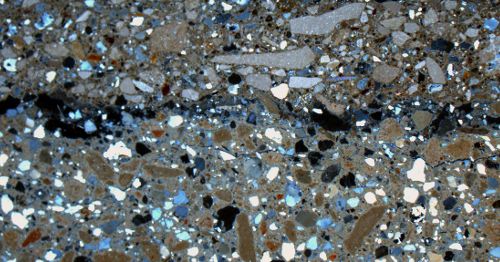

- Phase analysis

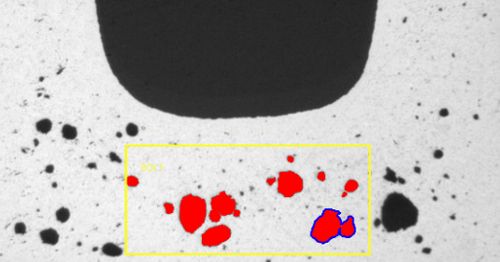

- Nonmetallic inclusion analysis

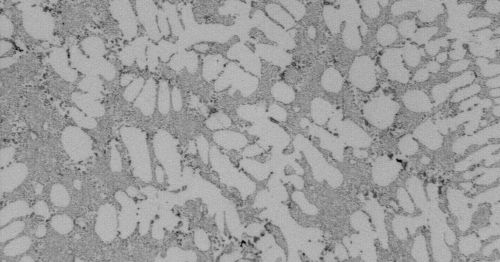

- Inspection on porosity

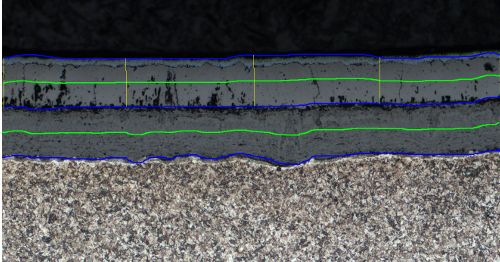

- Layer/coating thickness measurement

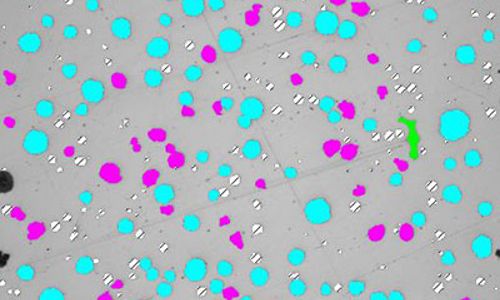

- Particle distribution analysis

- Graphite (morphological and quantification) analysis

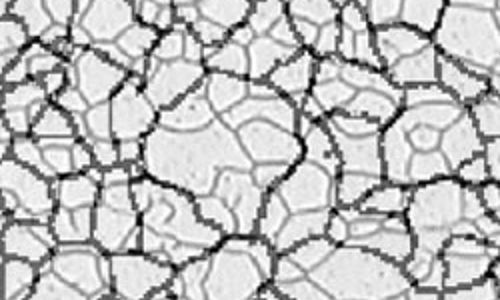

- Determination of dendrite arm spacing

Image Analysis Solutions for Materialography

Our industrial image analysis software has guided workflows to streamline material science analyses. These step-by-step instructions enable reproducible and reliable results. A range of optional Material Solutions can be added with dedicated workflows for material qualification and evaluation. These solutions enable you to conduct an analysis according to common international standards (ISO, ASTM, JIS, and DIN). Find solutions for a range of materials, including metal, ceramics, coatings, welds, aluminum alloys, and cast iron.

All material solutions can be implemented in PRECiV™ 2D image and measurement software and Stream Enterprise data management software.

PRECiV 2D Image and Measurement SoftwareSimple-to-use PRECiV software puts you in control of your microscope so that you can perform repetitive, 2D measurements during production, quality control, and inspection operations. | Stream Enterprise data management software (only available in EMEA region)Stream Enterprise data management software offers fast, efficient inspection workflows for all process steps for image acquisition, quantitative measurements and image analysis, reporting, and advanced materials science inspections tasks. |

Material Solutions

Grain Size |

Cast Iron |

Particle Distribution |

Non-Metallic Inclusion |

Porosity Analysis |

Phase Analysis |

Dendrite Arm Spacing |

Layer/Coating Thickness |

Chart Comparison |

Microscope Solutions for Materialography

We are a leading manufacturer of microscopes for materials science and industrial applications with over 100 years of experience in developing microscopes. Along with our image analysis software, we provide a wide range of microscopes for performing metallography and material analysis.

GX53 Inverted MicroscopeThe GX53 inverted microscope features exceptional image clarity and excellent resolution at high magnifications. With accessories such as a coded revolving nosepiece and software, the microscope's modular design makes it easy to customize for your requirements. |

BX53M Upright MicroscopeDesigned with modularity in mind, the BX3M series upright microscopes provide versatility for a wide variety of materials science and industrial applications. |

DSX1000 Digital MicroscopeThe DSX100 digital microscope combines ease of use with advanced features to streamline your inspection. The DSX100 system includes a large selection of the lenses that are easy to change, fast macro-to-micro viewing, and accurate measurements with a telecentric optical system. |

Digital Cameras for MicroscopesOur digital microscope cameras are designed exclusively for use with microscopes. Providing seamless compatibility with both our microscopes and image analysis software, our digital microscope cameras offer high live frame rates at full resolution. |

Materialography Applications

|

| ||||

|

| ||||

|

| ||||

|

|