IPLEX FX

Discontinued Products

Overview

This product has been discontinued, please check out our current videoscopes >>

IPLEX FX Industrial Videoscopes Instructions >>

A high-end industrial videoscope system combining portability with advanced functionality, and ease of use with durability. From high image quality inspection to retrieval operation, the versatility achieves various benefits beyond your experience.

Durability

The IPLEX FX introduces new levels of durability to industrial videoscopes with its shock-resistant case design and wear-resistant scope exterior. Adding "strength-of-construction" to a frequently used, job-essential tool produces one tough, reliable and long-lasting piece of industrial inspection equipment.

Cast Magnesium-Alloy Chassis for Impact Resistance

The main component of the IPLEX FX base unit chassis is Magnesium - renowned for its strength and light weight. A typical material used for industrial environment equipment, Magnesium was chosen to provide the impact resistance and solid base that withstands the knocks and bumps that commonly occur to industrial videoscopes. In addition to a crush-resistant chassis each corner is protected by rubber bumpers, further softening a drop and maximising product reliability while reducing potential for damage. The IPLEX FX survived the repetitive 4 feet drop test for compliance to MIL-STD 810G.*

*MIL-STD (The United States Defense Standard) is used to help achieve standardization objectives by the U.S. Department of Defense.

| Rubber bumper Magnesium-Alloy chassis |

See the Durability Test Scene>>

Abrasion Resistant Insertion Tube

The most critical component of any remote visual inspection tool is the insertion tube. It performs the basic requirement of accessing the inspection area and frequently navigating through narrow paths with abrasive and rough surfaces.

Tough TaperFlex coil

The Olympus Tough TaperFlex coil features graduated flexibility for easy scope maneuverability and navigation.

Inside resin tube

Articulation wires and electronics only. With LED illumination at the scope tip, fiber optic bundles are not necessary.

High-density braided exterior

High density outer braid fulfills durability and 3x greater fray resistance without compromising the flexibility and ability to navigate through the most difficult inspections.

Pliable distal end

To navigate through tight bends or corners, minimum bend radius and shorter rigid tip sections are an essential design criteria for our scope tip, optics and tip adapters.

Portability and Ruggedness

The simplicity and portability of Olympus videoscopes has seen their usage extend to areas not considered 'traditional' application areas. Go to these harsher environments, but take a system designed for the job… IPLEX FX.

True Portability - Compact, Lightweight, Battery-Powered

Power is provided to the FX by an internally mounted, Lithium-Ion battery which provides over two hours runtime. The compact size of the FX makes portable operation a reality - either body-wear the light weight system or place it on a surface and allow the non-slip, rubber corners to hold it in place while you carry out your inspections.

Temperature Resistance

The FX scope units are resistant to insertion in higher temperature environments - now 100°C (210°F) meaning that inspections can take place sooner as you won't need to wait as long for the area to cool. Additionally the 6.0mm and 4.0mm diameter scope units both feature a temperature sensor to provide a two-stage visual warning to prevent reaching an over-temperature situation.

Resistance to harsh environments

To prevent the ingress of debris, all mechanical joints are hermetically sealed and input/output connectors are covered.

To prevent the ingress of debris, all mechanical joints are hermetically sealed and input/output connectors are covered.

IPLEX FX complies with internationally recognised Military Standards (MILSTD 810F/G*1). This compliance assures a greater level of environmental performance than regular industry standards and provides increased reliability against dust and fluid. The inventive design of the FX has removed the need for a cooling fan, and therefore no air intake is required. This results in even greater environmental resistance.

IPLEX FX is MIL-STD 810F/G and MIL-STD 461F tested.

| MIL-STD 810F Tests: MIL-STD 810G Tests: MIL-STD 461F Test: |

*1 MIL-STD (The United States Defense Standard) is used to help achieve standardization objectives by the U.S. Department of Defense. Reference specification page for MIL-STD compliance details.

*2 IPLEX FX is not explosion-proof.

In support of this enhanced environmental resistance, the new daylight-Viewing high resolution LCD monitor provides clear observation of the inspection result when working outdoors, in strong sunlight.

See the Durability Test Scenes >>

Excellent insertion characteristics

The new, ultra-thin videoscope with a diameter of 4.0mm * is now available, greatly enhancing insertability due to its narrow tip. Navigating tight paths such as the insides of engines has never been easier.

*IPLEX scope diameters are specified as the minimum ring gauge diameter that the scope can pass through.

Image Quality

With our leading-edge optical and imaging technology, Olympus understands what is needed to deliver accurate and colour-rich images and this experience continues to be transferred to Industrial inspection equipment.

Daylight-view High Resolution LCD Monitor

Image comparison under strong illumination | Clear observation in strong sunlight is made possible with the new 6.5" daylight-viewing LCD monitor - the minimum recommended screen size for accurate and reliable observation of fine detail. Color reproduction and contrast are maintained, ensuring the inspection decision is not compromised when working outdoors. |

Optimised optical system with interchangeable LED tip adaptors

To provide high quality, faithfully reproduced images and accurate colour, the IPLEX FX features an outstanding optical system, noise reduction and our unique WiDER™ (Wide Dynamic Extended Range) image processing technology. WiDER™ delivers bright, contrast-balanced images across the entire depth of field.

New LED illumination with SmartTip™ tip adaptors

Now the light source is in the SmartTip™ optical adaptor with LED's providing illumination, meaning lamp changes are no longer required.

This revolutionary new design contributes to reduction in overall system size and power consumption, while maintaining the ability to change direction of view and field of view.

Additionally, Hi-Beam mode boosts illumination up to 2x for expanded inspection capability.

Versatility

The IPLEX FX can perform almost any kind of inspection thanks to a wide range of interchangeable scopes, including models up to 18 m long and one with a working channel. More than just another inspection tool, the IPLEX FX is a reliable, feature-rich system capable of precise, real-time measurement and foreign object retrieval.

Measurement Accuracy

The IPLEX FX uses Stereo Measurement technology for easy, three-dimensional defect measurement at any target angle. With the addition of Olympus' unique Multi and Offset Measurement modes, the IPLEX FX offers a more intuitive measurement environment with eight different modes for accurate evaluation of most inspection targets

IPLEX FX Stereo Measurement Modes

| Multi Measurement |

- Distance

- Point-to-line - Depth - Area - Lines - Profile - Multi - Offset (New) |

Multi Measurement mode is a quick two-point defect identification technique that simultaneously calculates point-to-line, area and distance results.

See demonstration of all measurement modes >>

| Spot-Ranging™ | Our unique IPLEX Spot-Ranging™ feature provides the industry's only live, real-time tip-to-target distance measurement. As a rule, videoscope measurement accuracy is dependent on the scope's distance from the measurement target. With the IPLEX FX, the user can easily determine whether the scope tip is close enough to calculate the most accurate and confident measurement on the first try. |

Interchangeable Scopes

The IPLEX FX offers a range of interchangeable scopes, allowing you to choose the right one to fit the job. This means a single IPLEX FX can be configured for a variety of inspections. Scopes are available in diameters of 4.0 mm and 6.0 mm and in various lengths ranging from 2 m to 18 m.

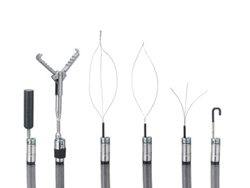

Foreign Object Retrieval

| Adding to the array of versatile IPLEX FX benefits is a 6.2 mm diameter scope featuring an internal working channel. Six retrieval tools allow you to remove foreign objects from inside inspection areas - ideal for helping avoid costly overhauls - and perform hook and drag inspections in engines. Both forward and side view Stereo Measurement tip adaptors are also available with the working channel scope, providing a complete inspection solution. |

See application images of the Retrieval tools >>

Image Management

These days, inspections don't end when you've packed up your borescope. It's just the beginning. The IPLEX FX is equipped with an array of recording options and external interface solutions for a seamless transition to post-inspection analysis, archiving and measurements.

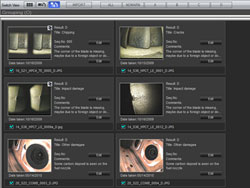

ImageNotepad™ for Extended Image Annotation

Information frequently needs to be added to a videoscope image to aid post-inspection diagnosis and report creation. IPLEX FX makes this process an integral part of the inspection, with the easy-to-use ImageNotepad™ tool. A title and multiple text fields are available for entering key words and phrases to enable extended descriptions of the inspected object to be documented.

|

Additionally, text input is simplified by displaying a list of predicted words each time a letter is entered. Connecting a USB keyboard to the IPLEX FX is also possible for further simplicity and speed of text entry.

This valuable data is then immediately available as part of the image when transferred to a PC. |

Inspection Recording Options

Archiving, sharing and reporting inspection results are made simple with the IPLEX FX. The IPLEX FX features still image and movie recording to internal memory, removable compact flash card or USB flash drive. Due to the rigours of the industrial inspection workplace, the IPLEX FX is designed to store images on solid-state media devices, ensuring that valuable data is not lost due to the instability of recording devices with movable parts. All recording formats are compatible with standard Windows operating systems and can be easily used in many report templates or attached to emails for instant sharing of inspection results. For other recording formats, the IPLEX FX is also compatible with many external recording devices through standard s-video and composite video outputs.

| CF Memory Card USB Flash Memory BNC output/ S-video output |

InHelp™ Inspection Assist Software

|

InHelp, the optional inspection data management and reporting software streamlines many aspects of remote visual inspections with the IPLEX. The software greatly improves work efficiency and simplifies inspections by organizing stored images on the IPLEX and generating detailed inspection reports on a PC with simple click-operation.

*Confirmed with Toshiba FlashAir Wireless LAN SD card |

Usability

With the IPLEX FX quick access control buttons and intuitive software menu, inspectors of all skill levels can easily utilise the advanced software features that produce accurate and confident inspection results.

One-handed scope control and interface

The ergonomic 750g scope handset is comfortable to use even during prolonged inspections and provides quick access to all frequently used menu commands. The unique IPLEX FX dual joystick design separates tip articulation and menu navigation, providing a more intuitive and comprehensible interface.

| TrueFeel ™ Scope Tip Articulation Quick-Access Hot Buttons |

SmartTip™ Automatic Recognition Technology

The IPLEX FX introduces the industry's first intelligent tip adapters. SmartTip optical tip adapters are uniquely identified allowing instant system settings change to match the tip adapter optics and features without the need for manual user selection.

With the mechanical reliability of double-threaded construction and the intelligence of automatic tip recognition, SmartTip™ adaptors also enable a warning message to be displayed should the tip start to become detached - giving you the opportunity to withdraw the scope and check the security of connection.