This application note explores how to measure the wall thickness of steam boiler tubes using electromagnetic acoustic transducers (EMATs). Learn all about EMATs in this application, including their advantages and limitations, how they work, and how to perform measurements using ultrasonic gauges and flaw detectors.

Importance of EMATs for Measuring the Wall Thickness of Steam Boiler Tubes

The very high temperatures found inside steam boilers (in excess of 800 degrees Celsius or 1472 degrees Fahrenheit) can cause the formation of a specific type of hard, brittle iron oxide called magnetite on the inside and outside surfaces of steel boiler tubing. The presence of this oxide layer on the outside of tubes can interfere with ultrasonic wall thickness measurements using common dual element transducers for two reasons: it can have a very rough surface that prevents proper sound coupling, and the oxide thickness is added to the steel thickness.

However, as its name implies, magnetite is magnetic, and that property permits the use of magnetostrictive electromagnetic acoustic transducers (EMATs), such as the E110-SB. EMATs offer several advantages over conventional dual element piezoelectric transducers: the need to remove oxide scale is eliminated, the scale thickness is not added into the wall thickness measurement, and measurements can be made quickly and without the need for liquid couplant.

The primary limitation of magnetostrictive EMATs is that they only work when scale is present and bonded to the outside of the boiler tube. Additionally, the minimum measurable wall thickness and measurement accuracy is not nearly as good as what can be achieved with a conventional dual element transducer, and EMATs are relatively insensitive to small internal pits. For these reasons, EMATs are often used for quick initial wall thickness surveys, while dual element transducers can then be used to take a closer look at areas of concern.

Theory of Operation

There are two types of EMATs used within the NDT industry. Those known as Lorentz EMATs do not require the presence of oxide scale, but they do require very high driving power. Magnetostrictive EMATs, such as E110-SB do require scale. However, these EMATs work at the much lower power levels typical of field-portable ultrasonic gauges and flaw detectors.

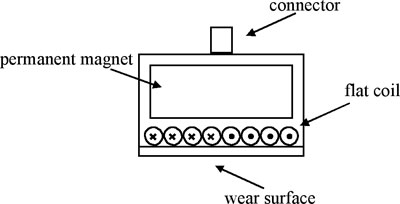

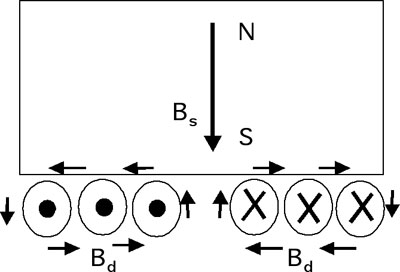

A magnetostructive EMAT consists of a strong permanent magnet and a coil, which acts as an electromagnet when driven by the excitation pulse from the test instrument, as seen in Figure 1. The permanent magnet creates a magnetic field perpendicular to the surface of the scale (Bs in the figure below), while the dynamic field created by the electromagnet (Bd) causes the scale to be pulled radially outward and inward as the coil is pulsed, as seen in Figure 2.

This motion generates a normal incidence shear wave in the scale, which then propagates into the steel. Essentially, the scale acts as the active transducer element to generate the sound pulse. The frequency of the sound pulse will vary as oxide thickness changes, increasing as oxide becomes thinner and decreasing as oxide becomes thicker. With typically thin scale buildups, the frequency will be approximately 5 MHz. The process also works in reverse to generate a voltage in the coil when the

returning shear wave echo vibrates the scale.

Figure 1. Cross section of a typical EMAT.

Figure 2. Method of sound wave generation.

Because the scale itself is the transducer element, scale roughness is not a coupling issue, and the scale is not added to the thickness measurement. The EMAT generates a shear wave, so the instrument must be calibrated to a shear wave velocity of approximately 0.1280 in./µs (3,240 m/s) in typical carbon steel. Typical measurement accuracy with the E110-SB EMAT is ± 0.010 in. (0.25 mm), with a minimum measurable thickness of at least 0.08

in. (2 mm) depending on material properties.

EMAT Setup and Measurement Procedures for Measuring the Wall Thickness in Steam Boiler Tubes

The quality of ultrasonic echoes in EMAT applications depends, in part, on the consistency of the oxide scale layer, which can vary from point to point on a given boiler tube. If usable echoes cannot be obtained at one point, try another point nearby. Also, the E110-SB transducer incorporates an adjustable standoff that varies the distance between the transducer face and the surface of the boiler tube. Adjusting this standoff distance helps optimize the echo response in many cases.

Here are two ways to set up the EMAT depending on your instrument:

1. Ultrasonic Thickness Gauge

The E110-SB transducer is used with the 39DL PLUS™ ultrasonic thickness gauge in conjunction with a 1/2XA/E110 adapter, which provides both probe recognition and the added high-pass filtering that is necessary for proper signal conditioning. When the adapter is plugged in, the gauge will automatically select the EMAT default setup of DEFM1-EMAT/E110.

As with any gauge setup, a two-point velocity/zero calibration should be performed on thick and thin reference standards of known thicknesses for optimum accuracy. If these standards are unavailable, the default settings are usually sufficient as a starting point.

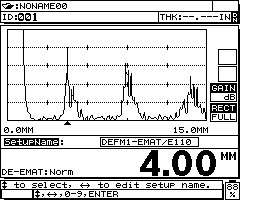

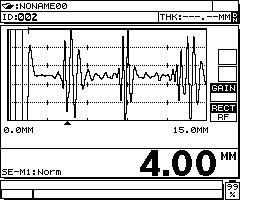

Instrument gain and echo blanking may be adjusted as necessary to optimize echo detection. Under the EMAT default setup, the 39DL PLUS gauge will display a full wave rectified waveform. Figure 3 shows a typical waveform display.

Figure 3. Typical rectified EMAT waveform. For a more detailed look at the shape of the waveform, which can be useful under challenging measurement conditions, select the RF display option on the gauge setup menu. Figure 4 shows a typical RF waveform from an EMAT measurement.

Figure 4. Typical RF EMAT waveform.

2. Ultrasonic Flaw Detector

Figure 5 shows a typical EMAT starting setup and waveform for an EPOCH™ series flaw detector, such as the EPOCH 6LT or EPOCH 650 instrument. Note that bandpass filtering must always be used to filter out low-frequency noise associated with EMATs. Also, because shear wave frequency varies with oxide scale thickness, the EPOCH flaw detector's square wave frequency should be adjusted as necessary to optimize the echo response.

Figure 5. Basic setup parameters: velocity, 0.1280 in./µs; zero, 0.650 µs; energy, 400 V; damping, 50 Ω; pulse frequency, 5.0 MHz; filter, 1.5–8.5 MHz.