PMI testing, or positive material identification, is a nondestructive testing (NDT) method used to verify the chemical composition of metals and alloys.

A common PMI testing approach is portable X-ray fluorescence (pXRF) since it can obtain immediate material identification on location for alloy manufacturing and installation. As a result, pXRF analyzers are sometimes referred to as PMI analyzers or alloy analyzers.

When properly set up, pXRF analyzers such as our Vanta™ handheld XRF help operators get the answers they need to make fast, informed decisions about critical components. Here are five tips to get your Vanta analyzer ready for efficient PMI testing:

Check the condition of your XRF analyzer window.

Before testing metal samples, perform a quick quality check on your analyzer window. Ask the following questions:

- Is the correct window installed? Vanta XRF analyzers come with different windows depending on the model and X-ray tube type.

- Is it intact? Does the window have any signs of puncture or tears? If you see any holes, make sure to install a clean window.

- Is it clean? If the window looks dirty, clean it with alcohol or a wet wipe to remove any dust or debris.

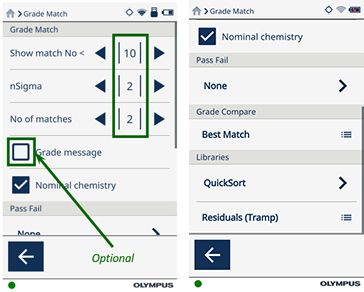

Configure your alloy grade match settings.

Alloy grade match settings control how alloy results are displayed on your analyzer’s screen. The factory settings for grade match are versatile but can be configured for specific applications. We suggest 10-2-2 for grade match settings in PMI testing, as shown below:

- Show match No: < 10

- nSigma: 2

- No of matches: 2

Recommended grade match configuration for PMI testing

These grade match settings (10-2-2) provide an optimal balance of grade matching to industrial specifications while also capturing common out-of-spec materials.

Make sure to use a version of the QuickSort grade library and use the Residuals (Tramp) residual library. The QuickSort grade library contains over 500 of the most common commercial alloy grades, optimized to give you the quickest grade match with maximum grade separation. Grade message, which displays any additional information about the grade, is optional.

Learn more about alloy grade match settings in the tutorial video below:

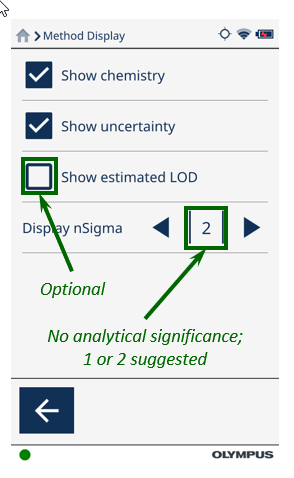

Check your method display settings.

In the method display settings, you can decide what information to show on the screen.

For PMI testing, show chemistry and uncertainty to see these results. Show estimated LOD, which displays the elements with results lower than the detection limits for the test, is optional. Checking this option is a great way to determine if a specific element is not detected above a specific threshold during a test.

Display nSigma has no impact on the grade matching or analytical results. You can select 1, 2, or 3 depending on the range of uncertainties that you want shown on the screen. A display nSigma of 1 or 2 is a common choice, but the Vanta analyzer’s precision is so high that the difference between the options is insignificant.

Recommended method display settings for PMI testing

Learn more about method display settings in the tutorial video below:

Optimize your test times for alloy analysis.

For efficient PMI testing, set your test times to get the alloy grade results you need in the shortest possible time. This can be done by simply selecting SmartSort, a rapid sorting method for alloy analysis.

Many alloys, such as aluminum, contain light elements (magnesium to sulfur) that need a longer, second beam test to be detected. Yet, light element analysis is unnecessary to identify the alloy grade in many cases. SmartSort automatically lengthens or shortens test times based on the material to help improve user productivity and throughput. Check out these examples for easy reference:

Recommended test times for PMI testing

Learn more about SmartSort in the tutorial video below:

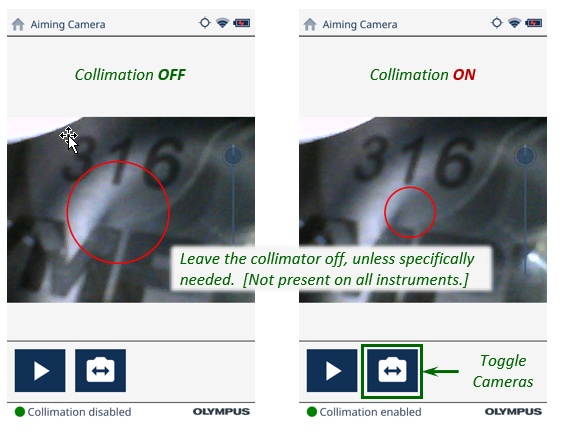

Confirm that the collimator is turned off.

The collimator narrows the X-ray beam to test a small area on your sample. This enables you to determine the chemistry of a specific area, such as a weld, and not the surrounding material. Turn off the collimator unless it is needed to take the fastest tests with the greatest precision.

Turning off the collimator broadens the testing area

The Importance of PMI Testing Using XRF Analyzers

Alloy mix-ups can lead to component failure in pipes, valves, welds, and other critical infrastructure. With XRF analyzers, inspectors can quickly determine the correct alloy installation at important locations to help prevent catastrophic or unplanned maintenance events. The Vanta handheld XRF analyzer provides alloy identification and chemistry results in seconds to help you meet quality control and safety compliance.

Related Content

Webinar: Basics of XRF for Positive Material Identification

API RP 578 Compliance and Training: Insights from a PMI Expert

Brochure: Vanta Handheld XRF for Positive Material Identification

Get In Touch