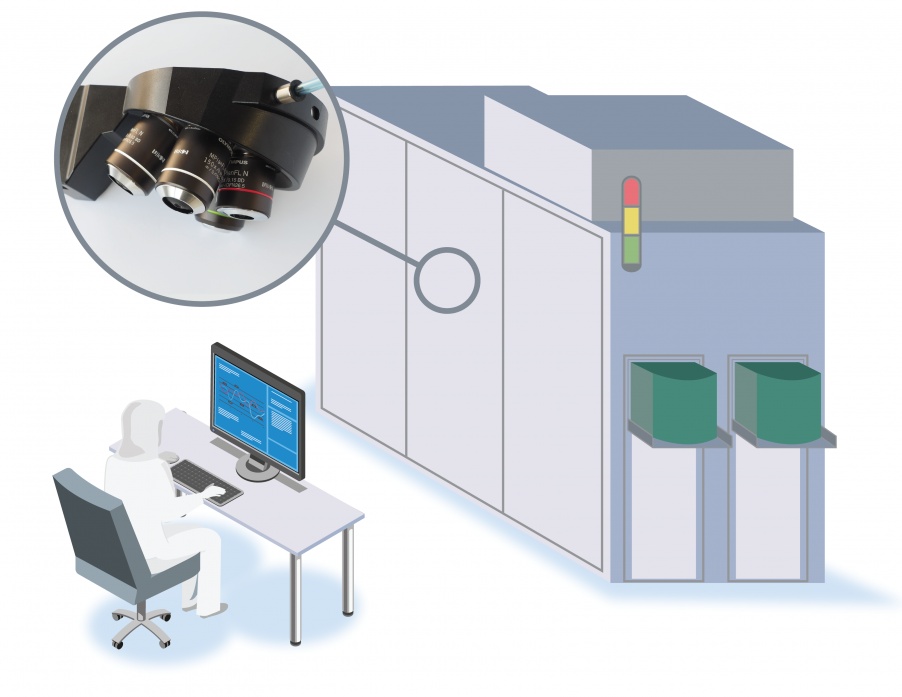

Designing metrology instruments that support high-throughput inspections (i.e., the number of inspections that can be processed per required time) is a common challenge in the semiconductor, flat panel display (FPD), and organic light-emitting diode (OLED) manufacturing industries.

As a leading supplier of OEM optics and components, Olympus provides high-quality microscope units to instrument designers that develop optical equipment for the inspection, production, and research fields. For quality inspection in the manufacturing industry, these units can improve yields (i.e., the percentage of non-defective items of all produced items) thanks to their thoughtful designs.

For instance, microscope units integrated into a high-throughput inspection device often need intuitive remote controls so that users of all skill levels can easily and accurately perform inspections. With simple controls, you can adjust the focus, sample observation location, observation methods, and magnification to quickly obtain an appropriate image for the inspection. We offer various units that enable motorized control, such as a motorized Z-driven microscope unit, motorized illuminator, motorized analyzer, control box, and hand switch.

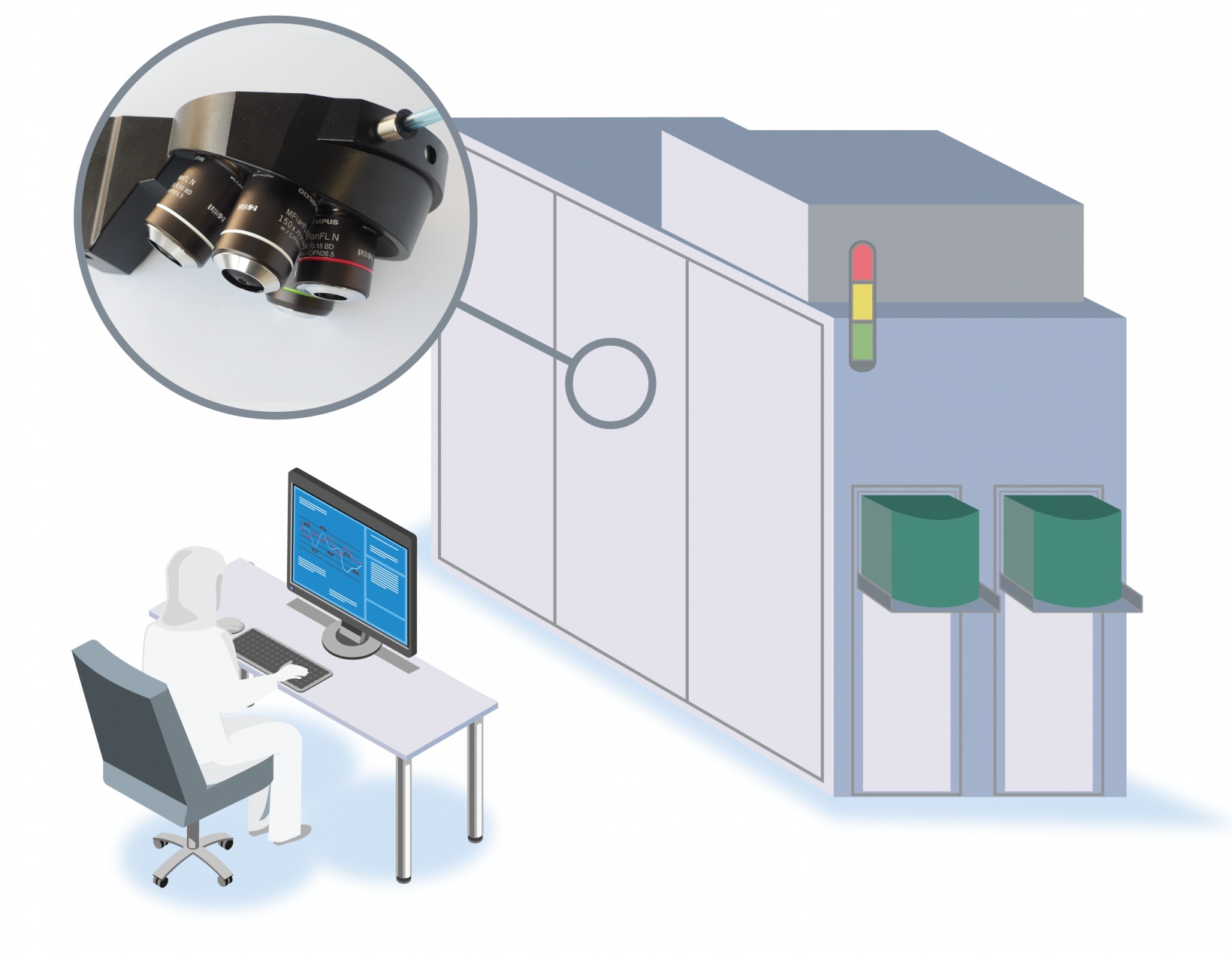

We are also introducing a motorized revolving nosepiece with a vacuum function (U-D5BDREMC-VA) that can improve cleanliness while offering speed and durability. For those who are unfamilar, a revolving nosepiece (also known as a revolving turret or objective revolving nosepiece) holds multiple objective lenses with different magnifications. By rotating the nosepiece, users can look at a sample using a different magnification as needed.

Motorized revolving nosepiece

Contamination Control in the Semiconductor, FPD, and OLED Industries

Cleanliness is a top concern for inspectors in the semiconductor, FPD, and OLED manufacturing industries to produce products that function properly. As a result, inspection equipment is used in enviornmentally controlled environments such as a cleanroom. Dust is not permitted to fall from the objective revolving nosepiece onto a sample, such as a semiconductor wafer. Even a tiny speck of dust can contaminate the wafer, destory its functionality, and impact the product yield.

Our motorized revolving nosepiece with a vaccum function (U-D5BDREMC-VA) uses low-pressure suction to reduce the amount of fine particles that fall when the revolving nosepiece rotates as well as capture any gas or dust created by the grease used to lubricate the system. This vacuum function makes the revolving nosepiece ideal for a controlled cleanroom environment. The revolving nosepiece can be used as a built-in microscope module for semiconductor and FPD inspection equipment.

Revolving nosepiece with vacuum function for contamination control

Various Revolving Nosepieces for Semiconductor Wafer Inspection and Beyond

We provide a wide range of revolving nosepieces that can integrate into systems for the inspection, production, and research fields. Our selection includes both manual and motorized options.

- Manual revolving nosepiece: Our range can support observation methods such as brightfield, darkfield, and differential interference contrast (DIC), can hold between four and seven objectives, meet ESD specifications, and more.

- Revolving nosepiece with a coding function: This type of manual revolving nosepiece can detect the objective mounting hole position of the nosepiece. Using software, you can match the objective's magnification information to its position on the nosepiece, enabling you to add the magnification information to the captured image faster while reducing the risk of manual data entry errors.

- Motorized revolving nosepiece: This type of revolving nosepiece moves five or six objectives electrically. A motorized revolving nosepiece with a vacuum function is also available.

- Revolving noisepiece with a centering function: This type of revolving nosepiece lets you center the optical axis of the objective lens manually or electrically. This changes the hole position of the revolving nosepiece to adjust for slight shifts in each objective lens. As a result, all the installed objective lenses can be aligned. With this adjustment, you can observe the exact same center position before and after changing the objective lens.

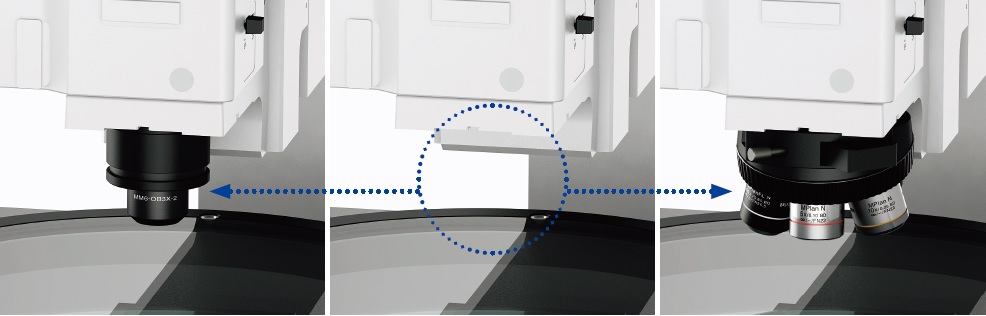

- Objective mount adaptor: This adaptor (STM7-MMOBAD) enables you to use just one objective lens. This is a cost-effective option if you don’t need multiple objective lenses for your application. Note that the adaptor only comes with the RMS screw W26 and does not have an optical path for darkfield illumination.

The objective mount adaptor (STM7-MMOBAD) provides flexibility by enabling you to attach just one objective lens to a system that suports multiple objectives. Left: a single objective lens is attached using the objective mount adaptor. Center: before attaching the nosepiece. Right: multiple objectives are attached using a revolving nosepiece.

To learn more about our OEM solutions, visit the OEM resource center on our life science site. Here you can download our device data sheets and 3D CAD data to get the specifications of our revolving nosepieces.

Related Content

Detecting Manufacturing Defects on Semiconductor Wafers Using a Digital Microscope

E-Book: Advanced Optical Metrology for Electronics

Circuit Pattern Inspection on Wafer Samples

Get In Touch