Fire and explosions are a major concern in many inspection applications, such as pipelines that carry gas or other flammable substances. No other aspect of industrial safety receives more attention in the form of codes, standards, technical papers, and engineering design. Industries that deal with hazardous materials or environments often impose strict processes, regulations, and equipment requirements for any potentially hazardous work, including routine nondestructive testing. In fact, even inspectors using regular flaw detectors are required to have hot work permits to inspect in certain locations.

To support our customers working in hazardous environments, we now offer three of our most popular instruments—the EPOCH® 650 flaw detector, the BondMaster® 600 multimode bond tester, and the NORTEC® 600 eddy current flaw detector—in versions that conform to the requirements of the ATEX directive. In addition to helping you save time and reduce cost, these EX series instruments can, most importantly, help keep you safe when working in certain hazardous environments.

What’s ATEX?

The acronym ATEX was originally derived from the French ATmosphères EXplosibles (or explosive atmospheres).

Today, ATEX is the name commonly given to the two European Union directives for controlling explosive atmospheres. The first is Directive 99/92/EX (also known as ‘ATEX 137’ or the ‘ATEX Workplace Directive’), and it regulates the minimum requirements for improving the health and safety protection of workers potentially at risk from explosive atmospheres. Directive 94/9/EC (also known as ‘ATEX 9’ or ‘the ATEX Equipment Directive’) regulates the equipment and protective systems intended for use in potentially explosive atmospheres. The regulations apply to all equipment intended for use in explosive atmospheres, whether electrical or mechanical.

What's an explosive atmosphere?

In simple terms, explosive atmospheres can be caused by flammable gases, mists, vapors, or combustible dust. When enough of these dangerous substances mix with air, they can explode if there’s an ignition source, such as a spark. Explosive atmospheres are a concern in the chemical, petrochemical, power generation, aviation, and mining industries. In some cases, a hot work permit or equipment that conforms to the ATEX directive may be required to complete the job.

Can Olympus’ ATEX-conforming instruments be used in any type of explosive atmosphere?

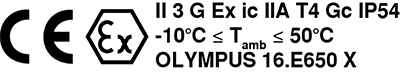

No. The requirements of the ATEX directive are complex, and the label on the instrument clearly explains what parts of the ATEX directive the instrument conforms to. The EPOCH 650 Ex, BondMaster 600 Ex, and NORTEC 600 Ex instruments all conform to the requirements of the ATEX directive with the same restrictions.

What do the letters and numbers on the instrument’s ATEX label mean?

The label tells you under what restrictions the instrument can be used in explosive atmospheres.

- CE: The instrument meets the safety, health, and environmental protection requirements of the European Economic Area

- Ex: Approved for use in explosive atmospheres

- II: Equipment group II, not approved for use in mines

- 3: Product category 3, approved for use in areas where flammable material is infrequently present or is present only for short periods of time

- G: Product category G, approved for use in gas, vapor, or mist-type explosive atmospheres (not dust)

- Ex ic: Intrinsic safety protection concept in normal operation (IEC Protection Level c)

- IIA: Gas group IIA, propane-type gases including acetone, petroleum fuel, ammonia, ethane, methanol, carbon monoxide, propane, n-butane, ethanol, diesel fuel, kerosene, avgas, and ethyl nitrate

- T4: Temperature class T4; exposed instrument components will not exceed 135 °C (275 °F)

- Gc: Equipment protection level Gc, for use in environments where explosive gases are present infrequently or for short periods only

- IP54: International Protection level IP54; instrument is protected from limited dust ingress and is protected from water spray from any direction

- -10 °C < T amb < 50 °C: Operating temperature range—EX instruments are rated for use in the previously specified hazardous environment from -10 °C to 50 °C (14 °F to 122 °F)

- OLYMPUS 16.EP650: Product ATEX certificate designation

- X: Equipment is intended for use only in the specific conditions described on the label

Is there a US equivalent to ATEX?

There is no direct equivalent. The US has a separate classification system based on the National Electric Code.

How does ATEX compare to intrinsically safe or explosion proof?

The phrase intrinsically safe is often used to describe products designed for hazardous (explosive) areas. Intrinsically safe is a protection concept based on limiting the available electrical energy to non-incendiary levels so that sparks that could cause an explosive atmosphere to ignite cannot occur.

Like intrinsically safe, explosion proof is a term that is often improperly used to describe industrial equipment. To earn an explosion proof rating, an enclosure must be able to contain any explosion originating within its housing and prevent sparks within the housing from exiting and igniting an explosive atmosphere surrounding the equipment.

EX series instruments can be considered intrinsically safe and explosion proof when properly operated within the environmental conditions specified on the ATEX label. It’s inaccurate to say that EX instruments are intrinsically safe or explosion proof without specifying the conditions under which the instruments conform to the requirements of the ATEX directive.

What’s the difference between ATEX, International Protection (IP) rating, and the MIL-STD-810 standard?

The International Protection (also known as ‘Ingress Protection’) rating consists of the letters IP followed by two numbers. The first number represents the degree of protection against the intrusion of solids (like dust) and the second number the degree of protection against the intrusion of water. The higher the number, the higher the level of protection (0–6 for solids and 0–8 for water).

ATEX goes beyond these standards and is geared specifically toward an instrument’s suitability for use in explosive atmospheres.

Are there any physical differences between a standard instrument and an ATEX instrument?

You may notice that the EX instruments are a little bigger and heavier than their non-EX counterparts. They also have an aluminum body instead of plastic, a damage-resistant screen protector, and their rubber bumpers are a different color. Perhaps most importantly, EX series instruments work exactly like the standard versions with the same features, functionality, and results you can trust.

Where can I use Olympus EX instruments?

EX series instruments are approved for use in environments where flammable propane-type gases (gas group IIA) are abnormally present at temperatures ranging from -10 °C to 50 °C. The EX instruments are not intended for use in atmospheres with explosive dust, environments where flammable gases are usually present, or mines.

How do I know if the areas where I work require the use of an ATEX-conforming flaw detector?

Determining the classification of a specific location requires a thorough understanding of the site. An exhaustive study of the site must be undertaken before a decision can be made as to what classification it should be assigned. Your local inspection authority is responsible for defining the classification of a specific area.

Want to learn more? Download the brochure

Get In Touch